In the modern narrow-web printing environment, achieving microscopic detail is no longer a luxury. It is a baseline requirement. Brands in the pharmaceutical, cosmetic, and premium beverage sectors demand crisp text, intricate gradients, and flawless barcodes. At the heart of this high-definition output lies a critical chemical and mechanical process: UV curing.

Understanding how UV curing influences print sharpness requires a look beyond the lamp itself. It involves the interaction between ink chemistry, substrate behavior, and the physics of light. Whether you operate a flexographic press or a high-speed offset line, the curing stage determines if your dots stay sharp or bleed into a blurry mess.

The Mechanics of Ink Migration and Dot Gain

To understand sharpness, we must first address dot gain. In traditional solvent or water-based printing, ink dries through evaporation or absorption. This takes time. During those fractions of a second, the ink droplet spreads across the substrate. In high-resolution designs, even a few microns of spread can ruin the legibility of a 2-point font or a dense QR code.

UV-curable inks change this dynamic entirely. These inks consist of liquid monomers, oligomers, and photoinitiators. They do not “dry” in the conventional sense. Instead, they undergo polymerization. When the ink hits the substrate, it remains a liquid until it passes under a UV light source.

The “instantaneous” nature of UV curing is what preserves sharpness. By transitioning the ink from a liquid to a solid state in milliseconds, the technology “freezes” the dot in its intended shape. This minimizes mechanical dot gain. In narrow-web flexo printing, where anilox rollers deliver precise volumes of ink, UV curing ensures that the volume stays contained within the specified area.

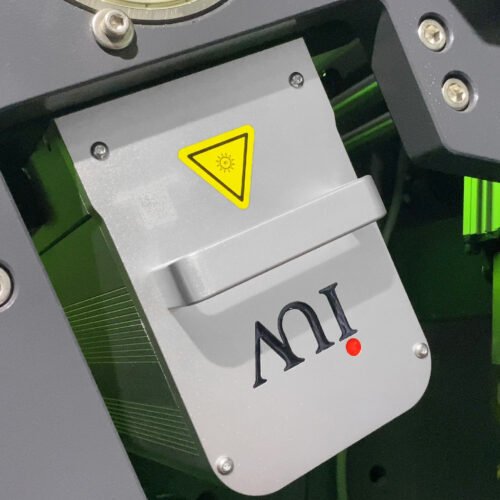

LED UV vs. Mercury Vapor: Precision in Curing

The printing industry has seen a massive shift toward LED UV curing, and for good reason. Traditional mercury vapor lamps emit a broad spectrum of light, including significant infrared radiation. This heat can cause thin film substrates to stretch or distort. If the substrate moves or deforms during the printing of multiple colors, registration suffers. Loss of registration is the primary enemy of sharpness in high-resolution designs.

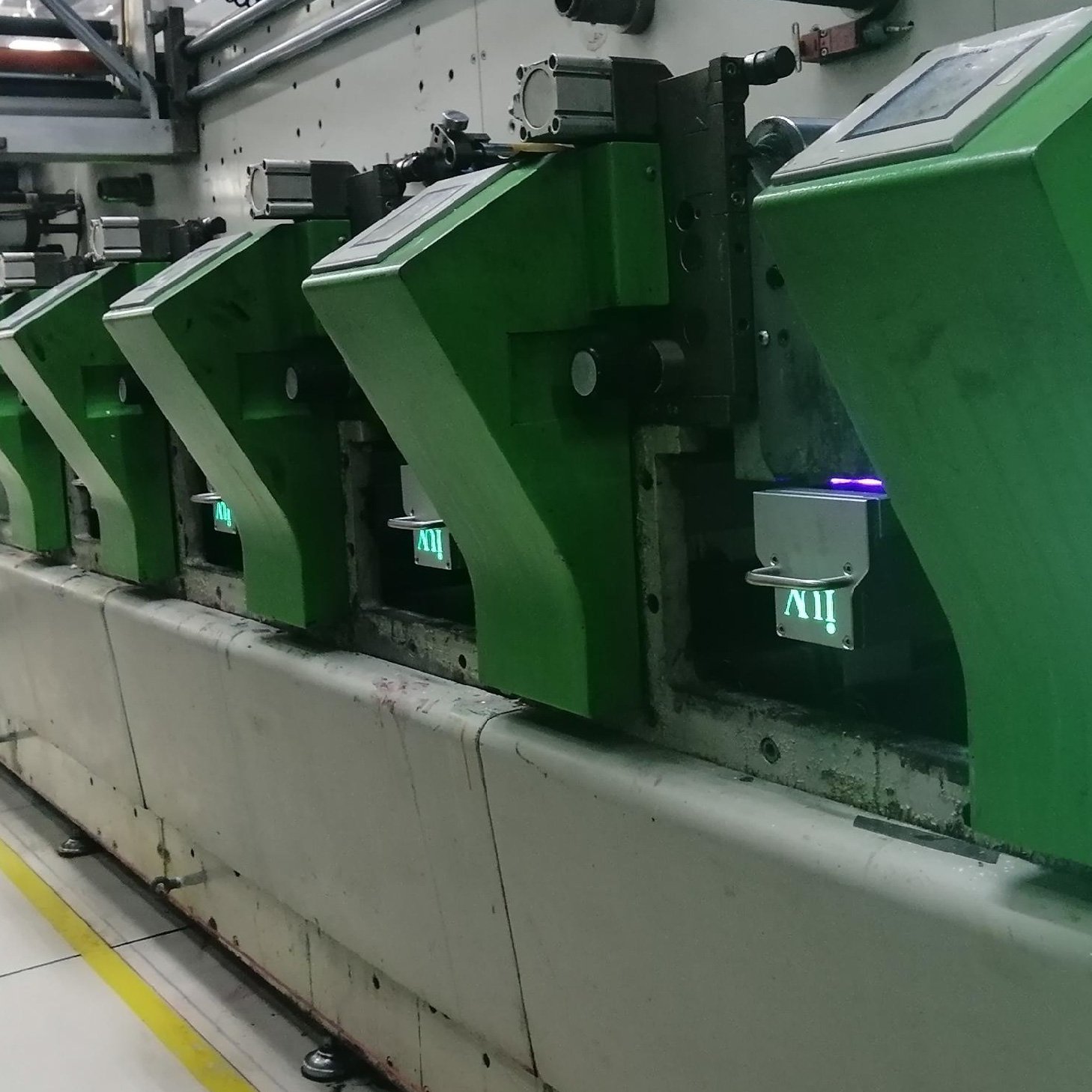

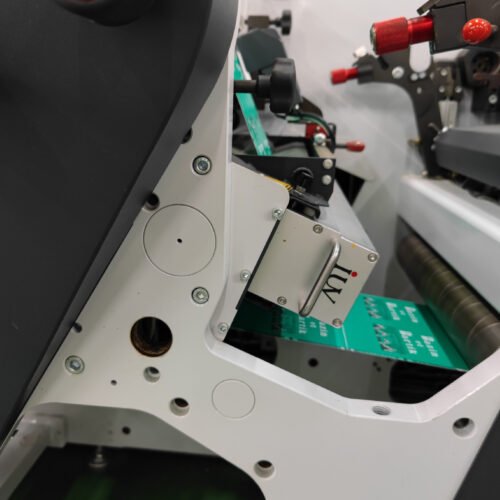

LED UV systems provide a monochromatic output, typically at 385nm or 395nm. More importantly, they operate at much lower temperatures. By keeping the substrate cool, LED UV prevents the “web-stretch” common in narrow-web applications. This thermal stability allows for tighter registration across eight, ten, or twelve color stations. When every color sits exactly where it belongs, the resulting image appears significantly sharper to the naked eye and under a loupe.

Furthermore, LED units provide consistent intensity across the entire web width. Traditional lamps degrade over time, leading to “soft” cures in certain zones. Inconsistent curing results in varying dot structures, which destroys the uniformity required for high-end labels.

Flexographic Printing and High-Resolution Detail

Flexography has evolved from a simple packaging process to a high-precision method capable of competing with digital and offset. This evolution is tied directly to UV ink performance. In flexo, the pressure between the plate and the substrate is a variable that engineers must control.

UV inks possess a higher viscosity compared to water-based alternatives. This higher viscosity, combined with rapid curing, allows for the use of high-count anilox rollers. You can deliver a thinner, more concentrated layer of pigment. Because the UV light solidifies the ink immediately after the nip point, the “squish” effect—where ink is pushed to the edges of the plate relief—is mitigated. This results in cleaner edges on text and finer highlight dots in four-color process work.

Offset Printing and the Pursuit of Lithographic Sharpness

In narrow-web offset printing, the ink film is much thinner than in flexo. Offset is prized for its ability to produce incredibly smooth vignettes and photographic quality. Here, UV curing plays a role in “trapping”—the ability of one ink layer to accept another.

When printing high-resolution designs on an offset press, the “wet-on-wet” UV process requires precise lamp calibration. If the first color is not pinned or cured correctly, the subsequent colors will blend at the edges, leading to a loss of definition. Advanced UV systems allow offset printers to maintain the integrity of 175 or 200-line screens without the risk of ink emulsification or smearing.

Substrate Interaction and Surface Tension

Sharpness is not just about the light; it is about how the substrate accepts the ink. High-resolution labels often use synthetic films like BOPP or PE. These materials have low surface energy, which can cause ink to “bead up” or crawl before it reaches the curing lamp.

Professional engineers use UV curing in conjunction with corona treatment to manage this. However, the speed of the UV cure is the final safeguard. By curing the ink before it has the opportunity to retract or spread due to surface tension imbalances, the equipment maintains the “edge definition” of the design. In high-resolution work, the transition between the inked area and the substrate must be a hard line. Any “wicking” or feathered edges will make the label look low-quality.

Oxygen Inhibition and Surface Cure

One technical hurdle in achieving sharpness is oxygen inhibition. In very thin ink films, oxygen in the atmosphere can interfere with the polymerization process at the very surface of the ink. This results in a “tacky” finish or slightly blurred surface details.

High-end UV systems, particularly those used in narrow-web applications, are designed to deliver high peak irradiance. This overwhelms the oxygen molecules and ensures a complete cure from the base of the ink film to the surface. For high-resolution labels, this means the fine details are physically robust. They won’t smudge or blur during the finishing stages, such as die-cutting or rewinding.

The Role of Wavelength and Photoinitiators

The chemistry of the ink must be tuned to the output of the UV lamp. If the photoinitiators in the ink do not match the wavelength of the LED or Mercury lamp, the cure will be incomplete. An incomplete cure leads to “dot gain under stress,” where the ink remains soft internally.

When the label passes through the rest of the press, rollers can slightly deform these soft dots. This leads to a subtle ghosting effect that ruins high-resolution clarity. Engineers must ensure that the spectral output of the curing system penetrates the entire ink layer. This is especially challenging with opaque whites or high-pigment blacks. Achieving sharpness in a high-density black background requires a UV system with enough “punch” to reach the bottom of the ink film instantaneously.

Impact on Barcodes and Micro-Text

In many label designs, sharpness is a functional requirement, not just an aesthetic one. Micro-text used for anti-counterfeiting and high-density barcodes for logistics require 100% accuracy. A barcode with soft edges may fail a verification scan.

UV curing provides the dimensional stability needed for these elements. Because the process is digital—either the light is on and the ink is cured, or it isn’t—there is very little “gray area” in the production of line work. This binary transition from liquid to solid is what allows narrow-web converters to hit the strict tolerances required by the GS1 standards for barcode quality.

Troubleshooting Sharpness Issues in the Pressroom

If a high-resolution design appears blurry despite using UV technology, engineers look at three main factors:

- Lamp Intensity vs. Press Speed: If the press is running too fast for the lamp’s output, the ink won’t solidify at the point of impact. This allows for microscopic spreading.

- Distance from Substrate: The “focal point” of the UV lamp is vital. If the lamp is even a few millimeters out of position, the irradiance drops, leading to a slower cure and loss of detail.

- Ink Viscosity: UV inks are temperature-sensitive. If the pressroom is too hot, the ink thins out, increasing the likelihood of dot gain before the curing unit.

By monitoring these variables, printers can maximize the capabilities of their UV hardware.

The Future of High-Resolution Curing

As we push toward even higher resolutions, the integration of UV sensors and “smart” curing systems is becoming common. These systems adjust power in real-time based on press speed and ink density. This level of control ensures that every label, from the first to the hundred-thousandth, maintains the same level of sharpness.

For the narrow-web industry, UV curing is the bridge between digital design files and physical reality. It allows the complex, high-resolution visions of brand owners to be realized on a wide variety of substrates without compromising on speed or quality. The sharp edges, vibrant colors, and fine details that define premium labels are all products of this controlled, light-speed chemical reaction.