Managing heat load during the UV curing process is one of the most persistent challenges in high-speed narrow web printing. As brand owners demand thinner, more sustainable films, the margin for thermal error shrinks. High-performance films like PE, BOPP, and shrinkable PVC or PETG react poorly to excessive infrared (IR) radiation. If the temperature exceeds the substrate’s threshold, you face registration shifts, web stretching, or even melting.

Controlling this heat load requires a deep understanding of the interplay between UV lamp physics, press mechanics, and ink chemistry. Whether you operate a flexographic press or a specialized offset line, the goal remains the same: achieve full polymerization without compromising the structural integrity of the film.

The Thermal Challenge in UV Curing

Conventional mercury vapor lamps are efficient at emitting the UV-A, UV-B, and UV-C wavelengths needed for curing. However, they also emit significant amounts of IR radiation. This IR energy translates directly into heat on the substrate surface. In narrow web flexo printing, where the distance between the lamp and the web is minimal, this heat can be intense.

The heat load isn’t just a byproduct of the lamp. The curing process itself is exothermic. When UV energy hits the photoinitiators in the ink, a chemical chain reaction begins. This reaction generates internal heat. When you combine the lamp’s IR output with the exothermic heat of the ink, thin films can quickly reach their glass transition temperature.

LED UV vs. Conventional Mercury Systems

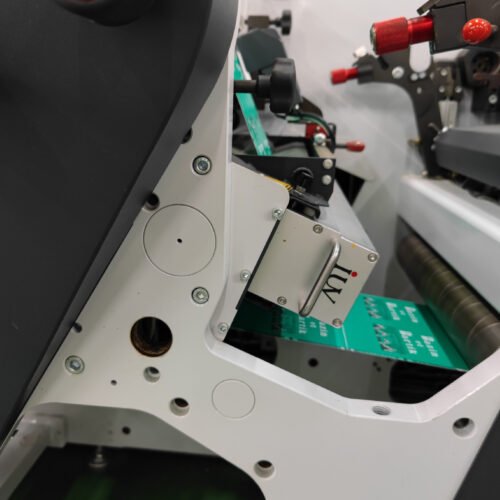

The industry has seen a massive shift toward LED UV curing for heat-sensitive applications. LED lamps emit a narrow band of UV light, typically around 385nm or 395nm. Unlike mercury lamps, LEDs do not emit IR radiation toward the substrate. This makes them inherently “cooler” from a radiative perspective.

However, a common misconception is that LED systems are heat-free. While the light itself lacks IR, the LED chips generate significant heat at the back of the lamp head. This heat must be managed via water-cooling systems. Furthermore, the high intensity of LED light can still trigger a rapid exothermic reaction in the ink. If you are running high-opacity whites or heavy ink loads on thin shrink sleeves, the temperature rise can still cause film distortion.

For printers using offset or flexo processes, switching to LED often allows for faster production speeds on films that were previously too “difficult” for traditional UV.

The Role of Chill Rollers in Heat Management

In any narrow web environment, the chill roller is the primary defense against heat-related defects. These rollers are positioned directly under or immediately after the UV lamp station. Their job is to pull heat out of the web as quickly as it is applied.

Effective chill roll management involves more than just turning on a water circulator. The temperature differential between the roller and the web must be precisely calibrated. If the roller is too cold, you risk condensation, which ruins ink adhesion. If it is too warm, it fails to “quench” the heat from the UV lamp.

In flexographic printing, the contact arc between the film and the chill roller is vital. Maximizing this contact area ensures better thermal transfer. Some modern presses use “active” chill drums where the UV lamp shines directly onto the film while it is backed by the cooled drum. This configuration provides the most consistent temperature control for ultra-thin films.

Optimizing Lamp Geometry and Reflectors

For those still using conventional mercury UV systems, reflector technology is a major factor in heat control. Standard reflectors bounce both UV and IR toward the web. Dichroic reflectors, often called “cold mirrors,” are designed to reflect UV light while absorbing or transmitting IR radiation away from the substrate.

Using dichroic reflectors can reduce the heat load on the web by up to 40%. Additionally, the focus of the lamp matters. An out-of-focus lamp spreads energy over a wider area, often requiring the operator to increase power to achieve a cure. A tightly focused beam delivers the necessary UV dose quickly, allowing the web to move past the heat source before the temperature spikes.

Airflow also plays a role. High-velocity air cooling within the lamp housing removes ozone and helps dissipate some of the ambient heat. However, the airflow must be balanced. Too much air can cool the lamp bulb itself, causing it to “drop out” of its optimal operating temperature and leading to under-cured ink.

Ink Chemistry and Cure Speed

The sensitivity of the film often dictates the chemistry of the ink. Low-migration inks and high-reactivity flexo inks are designed to cure with less total energy. The faster an ink cures, the less “dwell time” the web spends under the heat source.

When printing on heat-sensitive labels, the “dosage” of UV is more important than the “intensity.” Dosage is the total energy accumulated over time. By using highly reactive inks, you can run the lamps at lower power settings. This directly reduces the IR output and the thermal stress on the film.

In offset printing, where ink films are much thinner than in flexo, the heat load is generally lower. However, the complexity of the offset press means there are more rollers and components that can hold residual heat. Keeping the entire press environment stabilized is essential for maintaining consistent ink tack and preventing film stretching.

Monitoring and Process Control

You cannot control what you do not measure. Advanced label converters use wireless telemetry sensors or thermal labels to monitor the actual temperature of the web during a production run. Infrared thermometers (IR pyrometers) installed after the last curing station provide real-time data to the operator.

If the web temperature begins to creep upward, the operator can take several actions:

- Increase the press speed (reducing dwell time).

- Decrease UV power (if the cure remains stable).

- Lower the chill roll set point.

- Check the condition of the reflectors.

In many narrow web setups, “shuttering” systems are used during ramp-up or ramp-down. When the press slows, the UV lamps are either dimmed or mechanically shuttered to prevent a heat spike that would melt the stationary web.

The Impact of Substrate Choice

Not all “sensitive” films are created equal. PE (Polyethylene) is notoriously prone to stretching under heat. BOPP (Biaxially Oriented Polypropylene) is more stable but can still suffer from “oil canning” or puckering if the heat load is uneven. Shrink films like PETG are designed to react to heat; if your UV system pre-activates the shrink properties, the label will not fit the container correctly later in the process.

When working with these materials, the surface tension and the heat-sink properties of the film must be considered. Thicker films can absorb more heat before distorting, while 12-micron or 15-micron films have almost no thermal mass. On these thin gauges, LED curing combined with high-efficiency chill rolls is no longer optional; it is a requirement.

Practical Steps for Heat Reduction

To improve your results on sensitive films, start by auditing your current UV output. Often, lamps are run at 100% power simply because “that’s how we’ve always done it.” Testing to find the minimum viable power setting for a specific speed can significantly prolong lamp life and protect your substrate.

Regular maintenance is the second pillar of heat control. Dust on reflectors or clouded quartz plates forces the system to work harder. This leads to more heat for the same amount of usable UV light. Cleaning your reflectors weekly and replacing them according to the manufacturer’s schedule ensures that the energy hitting the web is high-quality UV rather than wasted IR.

Finally, consider the layout of your press. If you have several high-power UV stations in a row, the heat accumulates. Incorporating “cooling zones” or longer web paths between stations can allow the film to dissipate heat naturally into the ambient air before it hits the next lamp.

Achieving the Perfect Balance

Controlling UV heat load is a balancing act between physics and chemistry. The goal is to maximize the UV output needed for cross-linking while minimizing the thermal energy that threatens the film. By leveraging LED technology, maintaining high-performance chill rolls, and optimizing ink reactivity, printers can handle even the most delicate narrow web applications.

As the industry moves toward thinner and more sustainable materials, the ability to manage this thermal footprint will define the success of a printing operation. Precise control over the curing environment ensures that the final product—whether it’s a high-shrink sleeve or a clear-on-clear label—maintains its visual and structural integrity from the press to the shelf.