Registration stability is a primary quality metric in label manufacturing. Misregister leads to visible color shifts, wasted substrate, and costly rework. Narrow-web presses and high-speed flexo lines magnify small instabilities. LED UV curing introduces process advantages that directly reduce registration errors and improve overall run consistency.

Common registration challenges in label production

Web stretch and thermal expansion create misalignment across multiple colors. Ink film movement after print, before full cure, causes dot gain and edge haloing. Variable substrate tension and fluctuating dryer temperatures change web dimensions. High machine speeds reduce available dwell time for ink set, increasing the need for immediate fixation. Register problems are often a combination of mechanical, thermal, and fluid-dynamics factors.

Fundamentals of LED UV curing

LED systems emit narrow-band UV light, typically near 365–405 nm, with a majority of narrow-web applications centered at 395–405 nm. LEDs deliver high irradiance while producing minimal infrared output. Photoinitiators in ink formulations absorb the LED wavelength to initiate polymerization. Cure energy depends on intensity and exposure time, which must match press speeds and ink chemistry.

How LED UV curing improves registration stability

Immediate surface cure: LED systems create a rapid skin or gel on the ink surface. This stops lateral ink flow and tack build-up. As a result, printed edges remain sharp and registration-sensitive traps maintain their geometry.

Reduced thermal load: LEDs emit substantially less heat than mercury or medium-pressure lamps. Lower radiant heat minimizes substrate expansion and shrinkage. Reduced dimensional change on films and paper keeps color-to-color registration tighter.

Faster machine readiness: Immediate tack reduction allows for quicker winding, laminating, and overprinting. Minimizing the post-print dwell window reduces opportunities for web distortion.

Consistent output: LED modules age slowly and maintain stable irradiance. Consistent light delivery supports repeatable cure profiles across long runs. Stable curing helps keep registration consistent between job runs.

Lower ozone and IR: Absence of ozone generation and reduced infrared heating improves substrate dimensional stability. This is especially valuable on heat-sensitive facestocks and adhesives used in label stocks.

Process-specific benefits

Flexographic printing

Flexo relies on precise anilox metering and plate impression. LED curing reduces ink film reflow caused by heat, preserving dot shape. This is helpful with fine line work and reverse-out type. Rapid cure improves multi-pass and multiple-station jobs where set-off risk is high. LED systems enable tighter registration across repeat stations.

Gravure and rotary screen

Gravure prints high-density solids and is sensitive to ink transfer dynamics. Instant cure at the cylinder exit reduces leveling and web stretch. For rotary screen coatings, LED curing locks in coating edges and prevents bleed between adjacent varnish areas. The result is crisper sealing edges and better color placement.

Plate-based and letterpress processes

Plate impression and substrate resilience determine registration here. LED curing minimizes impression-related distortion by reducing heat buildup under impression rollers. Photopolymer plates and rubber counters face less heat fatigue with LED systems, maintaining stable press geometry over long runs.

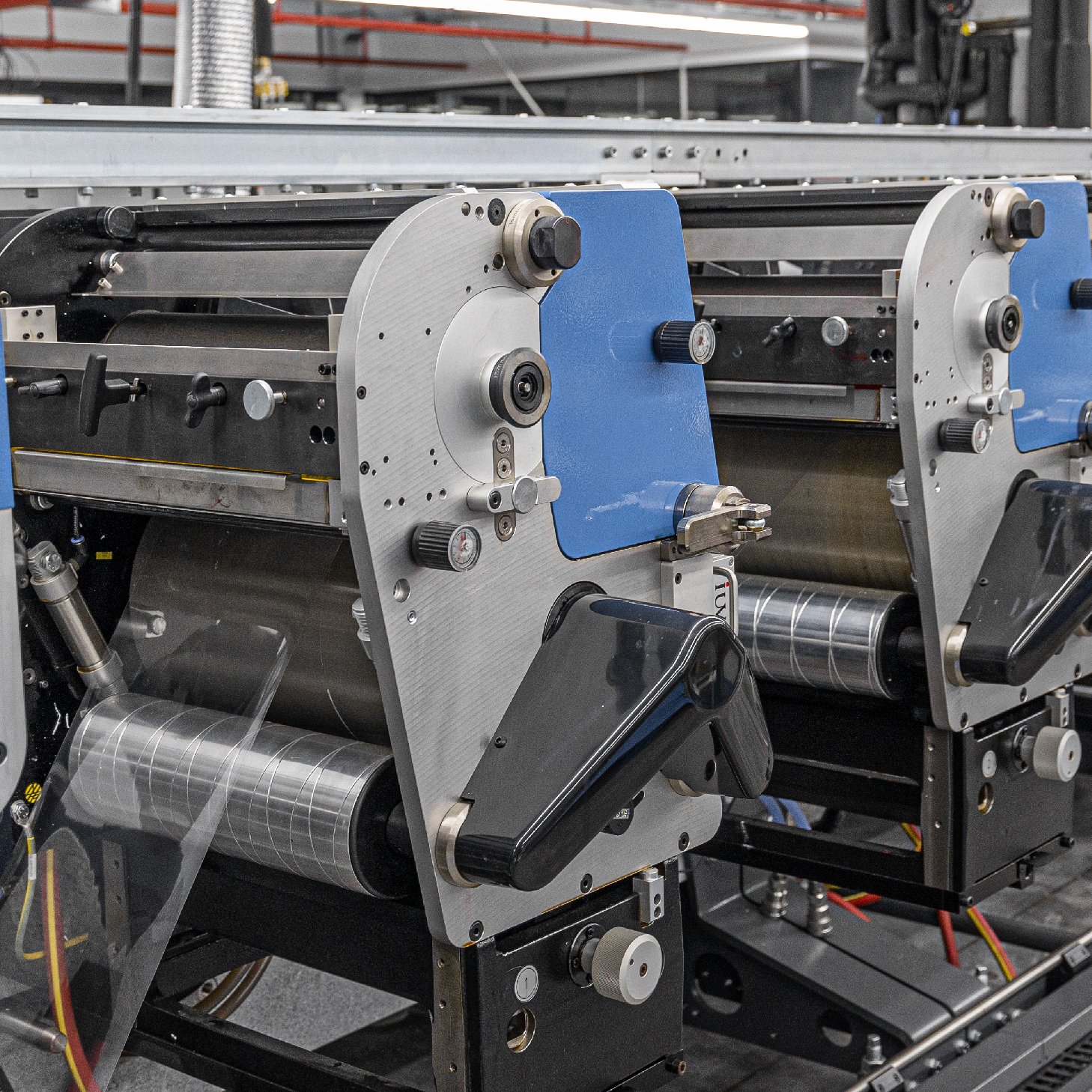

Narrow-web operations

Narrow-web presses run at high speeds and often handle delicate liner-backed facestocks. LED curing’s low heat output preserves liner adhesives and prevents curl. The compact size of LED modules allows placement close to the print nip, maximizing irradiance at the cured ink film and minimizing open time where misregistration can occur.

Ink and coating formulation considerations

LED-curable inks must contain photoinitiators tuned to the LED emission spectrum. Modern formulations use Type I and Type II photoinitiators to balance surface cure and through-cure. Pigment loading and opacity affect cure depth; heavier inks need adjusted energy or thinner layers. UV varnishes and cold-seal coatings should be tested for LED compatibility. Collaboration between ink supplier and press engineer accelerates optimization.

Substrate effects and control

Different facestocks respond differently to LED curing. PET and BOPP exhibit low thermal expansion, but they can show elastic stretch under tension. Paper stocks absorb ink and may deform slightly when wet; LED curing reduces wet-state deformation time. Proper tension control and unwind/rewind geometry remain critical even with LED systems. LED curing reduces a major source of dimensional change, but mechanical precision completes the solution.

Press setup and integration tips

Positioning LED modules close to the nip reduces required exposure time and helps consistent cure. Evaluate irradiance uniformity across the web width to avoid banding or variable cure. Implement inline intensity meters for real-time monitoring. Pair LED curing with stable, closed-loop tension control and high-precision servo-driven registration systems. Consider adding cooling for heat-sensitive components, although overall system heat is lower than conventional lamps.

Maintenance and operational advantages

LED modules require less maintenance than mercury lamps. They do not require warm-up and offer instant on/off control. No ozone extraction systems are typically necessary, simplifying ventilation design. Reduced maintenance downtime improves overall press uptime and helps maintain consistent registration over multiple jobs.

Troubleshooting common issues

Underexposure symptoms include tacky surface, blocking in rewinds, and poor adhesion. Verify photoinitiator compatibility and increase dose or reduce web speed. Overexposure can cause brittleness or increased haze; tune intensity and conveyor speed to balance. Non-uniform cure across width often stems from mismatched LED array alignment or aging modules; inspect irradiance profiles regularly.

Economic and sustainability implications

LED systems typically lower energy consumption and extend consumable lifetimes. Running at lower temperatures can reduce substrate waste caused by misregistration. Faster job turnarounds and lower scrap rates improve cost per label. Environmental benefits include elimination of mercury and reduced volatile emissions tied to heat-driven processes.

Case applications and performance metrics

Manufacturers often measure press performance in parts per million (ppm) of misregister or in repeatability over a run. Implementing LED curing frequently reduces color-to-color shift variance by measurable margins. Typical improvements include fewer rewinds, lower scrap, and faster line speeds without compromise. Metrics should include irradiance stability, on-press registration shift, and post-process curl or shrink.

Best practices summary

Select inks and coatings engineered for the LED spectral output. Place modules close to the point of transfer for maximal effectiveness. Maintain strict tension control and alignment across the web path. Monitor irradiance and replace modules on a scheduled basis. Run substrate compatibility trials before full production scale-up.

Final thoughts

Replacing or integrating LED curing into label presses addresses multiple root causes of registration loss. The combination of rapid surface cure, reduced heat, and consistent irradiance creates a more stable printing environment. When paired with precise mechanical control and matched consumables, LED UV curing delivers clearer edges, tighter traps, and fewer reprints on narrow-web and wide-label platforms.