The flexographic printing industry is undergoing a significant transformation. For decades, flexo presses have been the backbone of narrow-web label printing, flexible packaging, and various other applications. However, traditional UV curing methods, while effective, often come with substantial energy consumption and environmental considerations. This is where LED UV retrofit solutions enter the picture, offering a compelling pathway toward greater efficiency and sustainability.

The Evolving Landscape of UV Curing in Flexography

UV curing has long been a favored technology in flexographic printing due to its ability to achieve high print speeds and produce durable, high-quality results. Traditional mercury vapor lamps have been the standard for many years. These lamps utilize a broad spectrum of UV light, requiring significant electrical input to generate the necessary energy for ink polymerization. While effective, this broad spectrum also means a considerable amount of energy is converted into heat, which can impact the substrate and increase the demand for cooling systems. Furthermore, mercury lamps have a finite lifespan and pose disposal challenges due to their mercury content, raising environmental concerns for print shops striving for greener operations.

Understanding LED UV Technology

Light Emitting Diode (LED) UV technology represents a paradigm shift in UV curing. Unlike mercury lamps, LEDs emit UV light within a very narrow wavelength band, typically in the 395nm or 405nm range. This targeted emission is precisely matched to the absorption peaks of many UV-curable inks, coatings, and adhesives. This specificity is a key factor in its energy efficiency.

The operational mechanism of LEDs is fundamentally different. They generate light through the movement of electrons in a semiconductor material. This process is inherently more efficient in converting electricity into light, with less energy wasted as heat. This characteristic translates directly into lower power consumption compared to traditional UV lamps.

The Advantages of LED UV Retrofitting for Flexographic Presses

Migrating from traditional mercury lamps to LED UV systems on existing flexographic presses, often referred to as retrofitting, brings a cascade of benefits. The most immediate and impactful advantage is energy savings. Studies and real-world applications consistently show that LED UV systems can reduce energy consumption by 50% to 80% compared to conventional mercury lamp systems. This significant reduction directly lowers operational costs, a critical factor in today’s competitive print market.

Beyond cost savings, the environmental benefits are substantial. Reduced energy consumption means a smaller carbon footprint for the print operation. Furthermore, LED UV systems do not contain mercury, eliminating the hazardous waste associated with lamp disposal and aligning print businesses with increasingly stringent environmental regulations and customer demands for sustainable practices.

Enhanced Productivity and Print Quality

The benefits of LED UV retrofitting extend beyond just energy and environmental gains. The instant on/off capability of LEDs allows for immediate start-up and shutdown, eliminating the warm-up and cool-down periods associated with mercury lamps. This can lead to faster job changeovers and reduced waste during makeready.

Print quality can also see an improvement. The consistent and precise UV output from LEDs ensures reliable and thorough curing of inks and coatings. This leads to enhanced scratch resistance, chemical resistance, and overall durability of the printed product. For narrow-web label and packaging printers, where vibrant colors and sharp details are paramount, the consistent curing performance of LEDs can result in superior finished goods. The reduced heat generated by LEDs also means a wider range of heat-sensitive substrates can be printed without deformation or damage.

Key Considerations for LED UV Retrofit Options

When considering an LED UV retrofit for a flexographic press, several factors warrant careful evaluation. The primary consideration is the compatibility of the existing press with LED UV technology. This includes assessing the available space for the new curing units, the power supply capabilities of the press, and the exhaust/ventilation systems.

The choice of LED UV system itself is crucial. Different manufacturers offer various configurations, power outputs, and wavelength specificities. It is vital to select an LED system that is precisely matched to the UV inks, coatings, and adhesives being used. This often involves consulting with ink and LED system suppliers to ensure optimal performance and curing efficiency. The wavelength of the LED output is particularly important; 395nm and 405nm are common, but the exact formulation of the inks will dictate the best choice.

Implementing LED UV Retrofitting: A Practical Approach

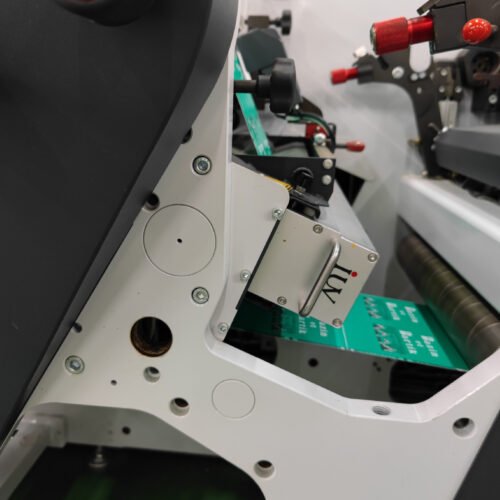

The process of retrofitting typically involves removing the old mercury lamp curing units and installing new LED UV curing modules. These modules are designed to integrate seamlessly into the existing press structure, often at each printing station or at the end of the press. Proper installation by experienced technicians is essential to ensure optimal alignment, airflow, and electrical connections.

For narrow-web flexographic presses, which are common in label and flexible packaging printing, LED UV retrofits are particularly well-suited. The compact nature of LED curing systems allows them to be easily integrated into the tight confines of these presses without significant modifications. The immediate curing capability is also highly beneficial for the high-speed production often seen in this sector.

The Economic Case for Going LED

While the initial investment in LED UV retrofit equipment might seem significant, the long-term economic benefits are undeniable. The substantial energy savings translate into reduced electricity bills, offering a clear return on investment (ROI). The extended lifespan of LED lamps (often tens of thousands of hours compared to a few thousand for mercury lamps) also reduces replacement costs and associated downtime.

Furthermore, the enhanced productivity, reduced waste, and potential for printing on a wider range of substrates can open up new business opportunities and increase overall profitability. As the market increasingly values sustainability, adopting LED UV technology can also serve as a powerful differentiator, attracting environmentally conscious clients and enhancing brand reputation.

Looking Ahead: The Future of Flexographic Curing

The trend towards energy efficiency and sustainability in the printing industry is undeniable. LED UV technology is at the forefront of this movement, offering a cleaner, more efficient, and often more effective solution for UV curing in flexographic printing. As the technology continues to mature and become more accessible, expect to see even wider adoption across all segments of the flexographic market, from narrow-web labels to wider packaging applications.

For printers looking to modernize their operations, reduce costs, and improve their environmental impact, exploring LED UV retrofit options for their flexographic presses is no longer just an option – it’s a strategic imperative for future success. The ability to achieve high-quality results while minimizing energy consumption and waste positions print businesses for a more sustainable and profitable future.