Enhanced print consistency has become a key focus in modern flexographic and narrow-width printing. Achieving uniform color, sharp details, and precise registration depends heavily on the curing process, which directly influences the final product’s quality. Among various curing methods, LED UV systems have emerged as revolutionary tools that bring unprecedented precision, stability, and efficiency to the industry.

The Role of LED UV Curing in Flexographic and Narrow-Width Printing

Flexographic printing involves transferring ink from an engraved plate onto substrates like labels, tags, and flexible packaging. Its reliance on quick drying and high-quality output places strict demands on the curing process. Traditional UV or hot-air drying methods often encounter issues such as inconsistent curing, extended processing times, and energy inefficiency.

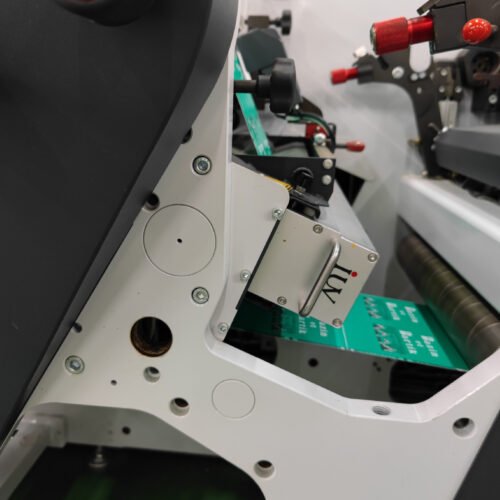

LED UV curing offers a compelling alternative by providing instant, uniform energy delivery that optimizes ink curing. Its compact form factor and low heat emission enable improvements in conveyor speeds and reduce substrate distortion, which are critical in thin or delicate substrates common in labels and narrow-width printing.

Why LED Curing Systems Improve Print Consistency

Consistent curing translates directly into consistent color density, sharper graphics, and stable registration. LED curing systems excel by maintaining a steady intensity over longer periods. Unlike traditional mercury vapor lamps that fluctuate in output and require frequent replacements, LEDs deliver consistent illumination, reducing variability between print runs.

This stability results in fewer curing-related issues like ink smudging, blocking, or incomplete curing. For flexible and label printing, where fine details and vibrant colors are vital, such precision ensures each print maintains its quality from start to finish.

Advantages of LED UV Systems in Label and Flexible Packaging Printing

LED UV units excel in curing a wide range of inks, varnishes, and adhesives tailored to label production. Their ability to cure at specific wavelengths enhances the adhesion and durability of printed images and coatings.

Energy efficiency is a major benefit. LED curing consumes significantly less power than traditional systems, reducing operational costs. Plus, the instant on/off feature means no warm-up time, improving throughput and minimizing downtime.

LED UV systems emit less heat, protecting sensitive substrates. This means labels and flexible packaging can be printed with high fidelity and minimal distortion, particularly on thin or heat-sensitive materials.

Enhancing Flexibility and Speed in Narrow-Band Printing

In narrow-width and specialty printing applications, speed and precision are vital. The rapid cure times provided by LED systems enable higher press speeds, boosting productivity without compromising quality.

Furthermore, the directional nature of LED light minimizes curing inconsistencies often caused by shadowing or uneven lamp coverage. This uniform curing ensures sharp registration, which is crucial in multi-color jobs and intricate designs common in labels and narrow-width applications.

How LED UV Curing Improves Color Consistency and Sharpness

Color accuracy is paramount in label printing, where branding relies heavily on precise tones. LED UV curing stabilizes ink radicals at the molecular level, reducing color variation caused by uneven drying or ink bleed.

In addition, the controlled energy ensures faster surface drying and deeper curing, leading to sharper edges and crisper images. The result is high-definition prints with vibrant colors and fine details that stay consistent throughout the production cycle.

Benefits for Sustainable and Eco-Friendly Packaging

LED curing systems play a key role in meeting sustainability goals. Their lower power consumption and absence of mercury or other hazardous materials make them safer for operators and more compliant with environmental standards.

Moreover, the ability to cure quickly with minimal energy reduces overall carbon footprint. These advantages support manufacturers aiming for eco-friendly label and flexible packaging production.

Future Trends and Innovations in LED Curing Technology

Advancements in LED UV technology continue to evolve, with innovations focusing on increased wavelength control, higher intensity outputs, and smart integration with digital workflows. These improvements will allow even finer control over curing parameters, further enhancing print quality and substrate compatibility.

Smart LED systems can dynamically adjust cure intensity based on ink type, substrate, and environmental conditions, ensuring optimal results at all times. As the industry leans toward automation, integrating LED UV systems with web-fed presses and digital printing modules will redefine efficiency standards.

Concluding Remarks

Implementing LED UV curing technology in label, flexographic, and narrow-width printing streamlines processes and elevates quality. The heightened consistency, speed, and environmental benefits position LED curing systems as indispensable assets for forward-looking printing operations. Through precise and stable curing, manufacturers can confidently deliver vibrant, sharp, and durable prints that meet the highest standards.