The label printing industry thrives on speed, precision, and adaptability—but sustainability is no longer optional. As brands demand eco-friendly solutions, LED UV curing has emerged as a game-changer for flexographic, offset, and narrow-web printing. Let’s cut through the noise and explore why this technology isn’t just a trend but a strategic upgrade for forward-thinking printers.

1. Slash Energy Costs Without Sacrificing Speed

Traditional mercury-arc UV systems guzzle energy. They run hot, require warm-up time, and waste power during idle periods. LED UV lamps, by contrast, operate at near-room temperature and activate instantly. No preheating. No standby mode. Just 70-80% less energy consumption.

For label converters running 24/7, this translates to lower utility bills and a smaller carbon footprint. A mid-sized narrow-web press switching to LED UV can save roughly 15,000 kWh annually—enough to power three households for a year.

2. Print on Anything (Yes, Even Compostable Materials)

PET labels? Recycled paper? Heat-sensitive substrates? LED UV’s cold-cure process handles them all. Unlike thermal curing methods, which can warp thin films or melt adhesives, LED UV instantly cross-links inks without excess heat.

This unlocks opportunities in sustainable packaging:

- Biodegradable labels for organic products

- Wash-off tags for glass recycling

- Compostable wine bottle sleeves

No more compromising material choices to accommodate curing limitations.

3. Ditch Hazardous Waste—Inks That Stay Put

Solvent-based inks release volatile organic compounds (VOCs). Even conventional UV inks contain photoinitiators that can migrate over time. LED UV formulations are leaner—fewer additives, zero solvents.

The result?

- No VOC emissions to scrub from exhaust systems

- Inks that cure fully, eliminating washup solvents

- Safer working conditions for press operators

California’s SCAQMD already classifies LED UV as a “near-zero” emission technology. Regulatory compliance just got simpler.

4. Turn Presses into Profit Engines with Faster Turnarounds

Time is money. LED UV’s instant curing slashes production bottlenecks:

- Print → Cure → Convert in a single pass

- No drying tunnels needed

- Immediate die-cutting or lamination

A flexo printer using LED UV reported a 40% throughput increase—translating to 12 extra jobs per month. For short-run labels (craft beer, limited editions), this agility is pure competitive edge.

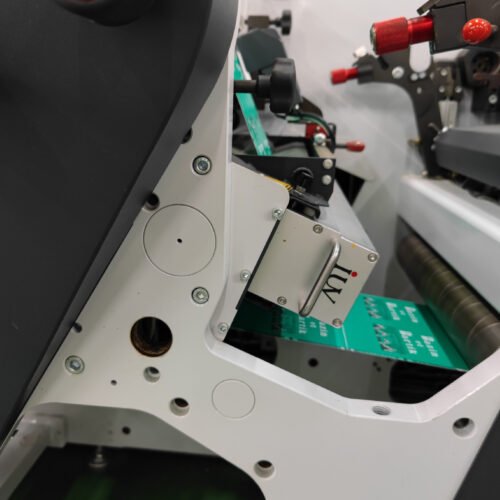

5. Future-Proof with Modular Upgrades

Retrofitting old kit? Most UV systems bolt onto existing presses. LED arrays fit into tight spaces—perfect for narrow-web gear. Maintenance is minimal: swap lamps every 20,000 hours (vs. 1,000 for mercury bulbs).

Key specs to evaluate:

- Wavelength compatibility (385-405nm suits most inks)

- Irradiance levels (higher = faster cure)

- Cooling requirements (air vs. water)

The Bottom Line

LED UV curing isn’t about being “green” for PR points. It’s about cutting costs, expanding capabilities, and meeting buyer demands for cleaner supply chains. Brands like L’Oréal and Patagonia now mandate sustainable labeling—can your shop afford to ignore that pull?

For converters straddling offset, flexo, and digital workflows, LED UV bridges the gap between high-quality print and planetary responsibility. The ROI isn’t hypothetical: one Wisconsin label plant recouped their LED investment in 14 months through energy savings alone.

Still clinging to thermal curing? Your competitors aren’t.

Need to optimize your UV curing setup? Let’s talk wavelengths, ink chemistry, and press configurations. The right tweaks can turn your labels into sustainability statements—without bleeding profit margins.