Efficiency on a narrow web press often comes down to the smallest components. As press speeds increase and job changeovers become more frequent, the demand for reliable, high-speed curing grows. Traditional mercury arc lamps served the industry for decades. However, the engineering shift toward Compact LED UV Curing Modules is no longer a trend; it is a standard for high-performance label and flexible packaging production.

This review examines the technical integration, performance metrics, and operational advantages of these modules from the perspective of a pressroom engineer.

The Engineering Logic Behind Compactness

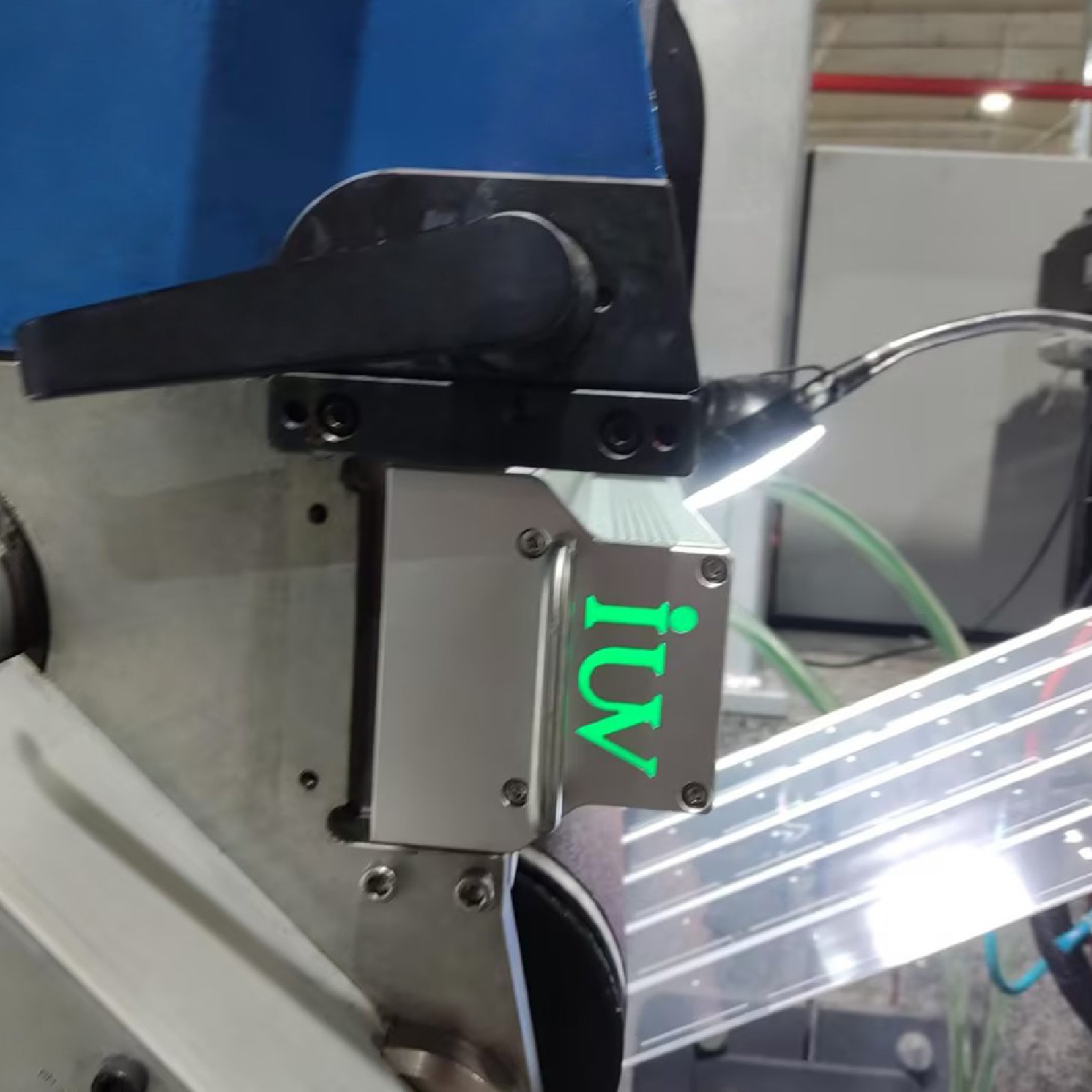

Space is the most valuable commodity on a narrow web press. Whether you operate a Mark Andy, Nilpeter, or Gallus, the bridge between printing stations is limited. Compact LED modules solve a primary mechanical problem: integration. Traditional UV housings are bulky, requiring massive shutter mechanisms and extensive ducting for ozone extraction.

Compact LED units eliminate these requirements. By removing the shutters and the large cooling blowers, engineers can fit curing power into tight spaces that were previously inaccessible. This small footprint allows for better web paths and shorter leads between stations. Shorter web paths lead to less waste during setup, directly impacting the bottom line.

Spectral Output and Ink Chemistry

UV LED technology operates on a narrow spectral band, typically centered at 385nm or 395nm. Mercury lamps provide a broad-spectrum output. Switching to LED requires an understanding of how photoinitiators react.

In flexographic and offset printing, the ink must be formulated to match the LED wavelength. When the peaks align, the polymerization process is nearly instantaneous. Because LED modules emit a concentrated “peak irradiance,” the surface cure of the ink is often harder and more scratch-resistant than what we see with mercury.

For engineers, this means consistency. A mercury lamp degrades over its 1,000-hour life, shifting its output. An LED module maintains its spectral integrity for over 20,000 hours. You get the same cure on Monday morning as you do on Friday night.

Thermal Management in Narrow Web Applications

Heat is the enemy of thin film substrates. In label printing, materials like PE, PP, and shrink sleeves are prone to warping or melting under the intense infrared heat of mercury lamps. Mercury lamps emit about 70% of their energy as heat.

LED modules are different. They are “cold” curing sources. While the LEDs themselves generate heat on the backside of the board, the light directed at the substrate contains no infrared radiation.

We manage this heat through two primary methods:

- Air-Cooled Systems: These are easier to install. They use high-velocity fans within the compact housing. They are ideal for standard label stocks and moderate speeds.

- Water-Cooled Systems: For high-speed wide-format or heavy-ink-laydown flexo, water cooling is superior. It keeps the module at a constant temperature, extending the life of the diodes and allowing for a smaller lamp head.

From a maintenance standpoint, water-cooled systems require a chiller, but they eliminate the risk of dust being sucked into the lamp housing, which is a common failure point in dusty print shops.

Performance in Flexo and Offset Environments

Flexographic printing relies on high-volume production. Compact LED modules provide the “instant-on/off” capability that mercury systems lack. There is no warm-up or cool-down cycle. When the press stops, the light shuts off instantly. This prevents the web from burning while stationary.

In offset printing, the challenge is oxygen inhibition. Because offset ink films are very thin, oxygen in the air can interfere with the curing process at the surface. Modern compact LED modules overcome this by using high-peak irradiance. By hitting the ink with a massive amount of photons in a tiny fraction of a second, the polymerization outpaces the oxygen interference. This results in a high-gloss finish without the “tacky” feel often associated with poorly cured UV offset.

Peak Irradiance vs. Energy Density

When evaluating these modules, engineers must distinguish between peak irradiance and energy density (dose).

- Peak Irradiance is the intensity of the light at its strongest point. This is measured in W/cm². High peak irradiance is what starts the curing reaction.

- Energy Density is the total amount of energy the web receives as it passes under the lamp. This is measured in mJ/cm².

Compact LED modules are designed to maximize peak irradiance. Because the diodes are positioned very close to the web—often within 10mm to 20mm—the light does not scatter. This proximity allows a 12W or 16W LED module to outperform a 400W/inch mercury lamp in terms of actual curing efficiency.

Maintenance and Operational Longevity

The shift to LED significantly changes the maintenance schedule of a narrow web press. Traditional systems require bulb changes, reflector cleaning, and shutter calibrations. If a shutter jams, the press goes down.

LED modules are solid-state devices. They have no moving parts (except for external fans in air-cooled models). The diodes do not “burn out” suddenly. Instead, they very slowly lose intensity over several years. This predictable decay allows for planned upgrades rather than emergency repairs.

For a pressroom manager, this translates to increased “Up-Time.” You no longer need to keep a cabinet full of expensive, fragile mercury bulbs. You also eliminate the hazardous waste disposal costs associated with mercury.

Integration with Smart Press Controls

Modern compact LED modules are designed for the “Industry 4.0” era. They feature digital interfaces that communicate directly with the press PLC (Programmable Logic Controller).

Engineers can program the lamps to scale their output automatically based on press speed. If the press slows down for a roll change, the LED intensity drops proportionally. This prevents over-curing, which can make labels brittle and lead to die-cutting issues. Furthermore, these modules provide real-time feedback on the health of individual diode segments, allowing for proactive monitoring of the curing system.

ROI: The Business Case for Engineers

The initial capital expenditure for LED is higher than mercury. However, the Return on Investment (ROI) is usually realized within 12 to 18 months in a multi-shift operation.

The savings come from three areas:

- Energy Consumption: LED systems use 50% to 70% less electricity. You aren’t paying to power a lamp during make-ready or when the press is idle.

- Scrap Reduction: Instant curing and lower heat mean fewer ruined rolls during startup and stops.

- Insurance and Safety: Removing high-voltage mercury systems and ozone emissions creates a safer work environment. This can lead to lower insurance premiums and fewer regulatory hurdles regarding air quality.

Selecting the Right Module for Your Press

Not all compact LED modules are created equal. When reviewing specifications, engineers should look at the “window” of the lamp. A wider curing window allows for more dwell time, which is helpful for heavy whites or thick varnishes.

Check the cooling manifold. Is it made of high-grade aluminum? Is the protective glass easily replaceable if ink splatters on it? These small design details determine how much frustration the crew will face during a busy shift.

Furthermore, consider the “form factor.” Some modules are designed to be “plug-and-play” replacements for existing mercury housings. These are excellent for retrofitting older narrow web presses that still have plenty of mechanical life but outdated curing technology.

Technical Outlook

The engineering behind compact LED UV curing has reached a level of maturity where the risks are minimal. We are seeing a move toward “hybrid” systems where a press can run both LED and mercury, but as ink technology improves, the need for mercury is vanishing.

For the narrow web industry—specifically labels and packaging—the compact LED module is the heart of a modern, efficient production line. It provides the thermal stability required for thin films, the speed required for high-volume flexo, and the precision required for high-end offset.

Upgrading to these modules is a strategic technical decision. It moves a facility away from the maintenance-heavy, energy-draining methods of the past. It positions the plant to handle more complex substrates and more demanding client specifications with confidence.

As a process engineer, my review is clear: the integration of compact LED UV modules is the most effective way to modernize a narrow web operation today. The technical benefits in heat control and spectral consistency far outweigh the transition costs, leading to a more stable, profitable, and clean printing environment.