Optimizing UV Curing for High-Speed Variable Data Label Printing

Variable Data Printing (VDP) has transformed the narrow-web label industry. It allows for unique barcodes, serial numbers, and personalized graphics on every single label. However, the success of a VDP run depends heavily on the curing stage. If the UV ink or coating does not cure instantly, the variable information smudges or bleeds. This ruins the entire batch.

Achieving a perfect cure at high speeds requires a deep understanding of UV LED technology and traditional mercury systems. You must also consider how these systems integrate with flexographic and offset presses. This guide provides a technical roadmap for setting up your UV curing environment specifically for variable data.

Assessing Your Press Configuration

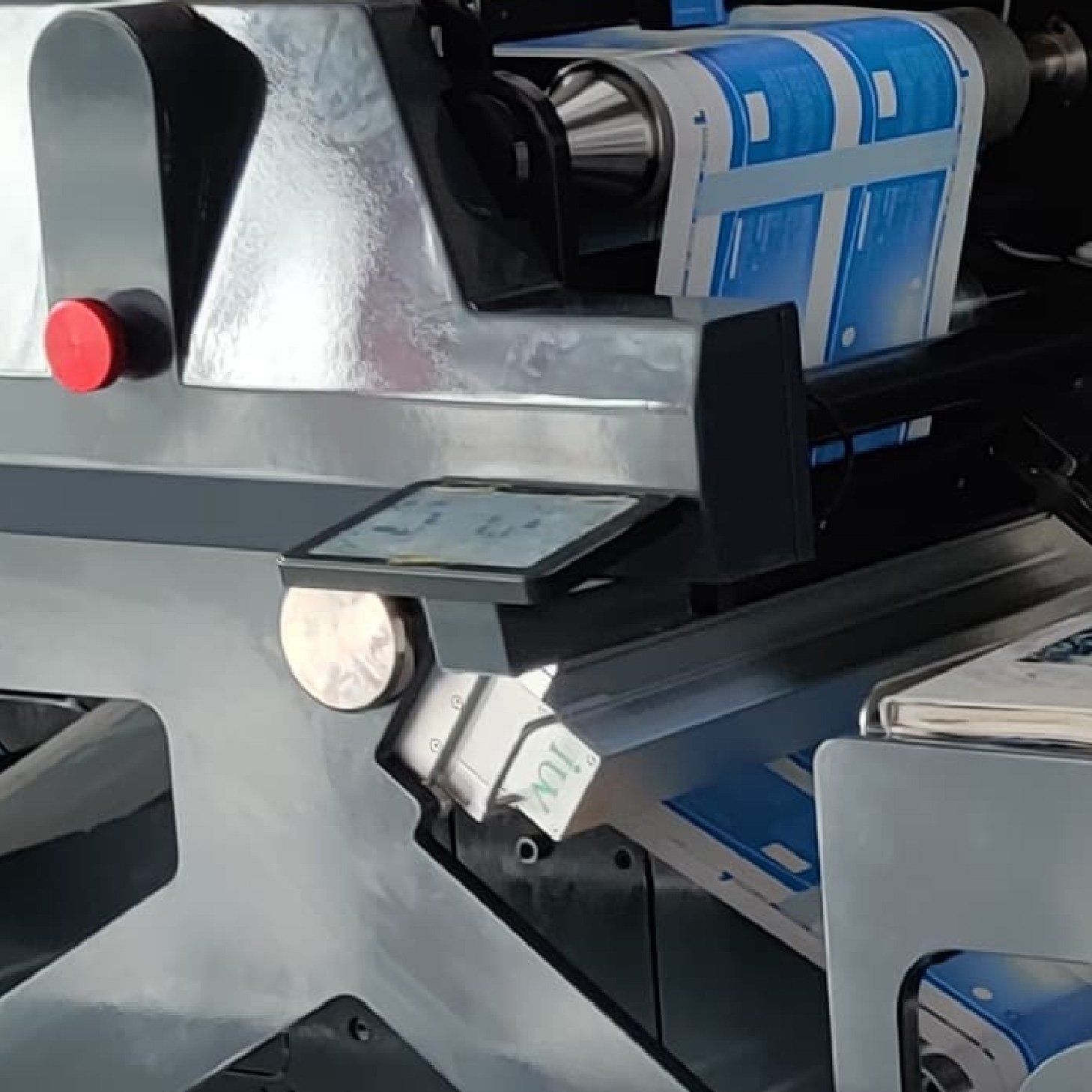

Before installing any curing hardware, evaluate your current narrow-web setup. Most VDP applications involve an inkjet engine integrated into a flexo or offset press. This hybrid approach combines the speed of traditional printing with the flexibility of digital data.

Flexographic presses use anilox rollers to transfer a specific volume of ink. This results in a consistent ink film thickness. Offset presses, conversely, use a complex series of rollers to achieve a very thin ink layer. VDP inkjet heads often deposit more ink than offset units. This higher volume requires more UV energy to reach the bottom of the ink layer.

Ensure your press has enough space for the curing lamps. In narrow-web setups, space is tight. Compact UV LED arrays are usually the best fit. They offer a smaller footprint compared to bulky mercury lamp housings and shutter systems.

Selecting the Right UV Light Source

You have two primary choices: UV LED or traditional Mercury Vapor lamps. For variable data, UV LED is rapidly becoming the industry standard.

UV LED Curing

LED systems emit a narrow band of UV light, typically at 365nm, 385nm, or 395nm. The 395nm wavelength is common for thick inkjet inks used in VDP. It penetrates deeper into the ink film. LED units offer instant on/off capabilities. This is vital for VDP because it eliminates the warm-up and cool-down cycles associated with mercury lamps.

Mercury Vapor Lamps

These lamps provide a broad spectrum of UV light. They are effective for curing a wide variety of coatings and inks simultaneously. However, they generate significant heat (infrared radiation). This heat can distort thin films and heat-sensitive label stocks. If your VDP job uses specialty plastics, Mercury lamps might require expensive chill rollers to protect the substrate.

Managing the Wavelength and Ink Chemistry

UV curing is a photochemical reaction. The photoinitiators in the ink must match the wavelength of the light source. If you use a 395nm LED lamp, your VDP ink must be “LED-tuned.”

Using standard UV inks with an LED system leads to “tacky” surfaces. This happens because the photoinitiators are not receiving the specific wavelengths they need to trigger polymerization. Always verify the technical data sheet (TDS) of your ink. Ensure the absorption peaks align with your lamp’s output.

In flexo-hybrid VDP, you might have a flexo-printed background cured by mercury lamps and digital text cured by LED. This “mixed-lamp” environment requires careful ink management to avoid cross-contamination between different ink types.

Positioning and Focal Distance

The physical placement of the UV lamp determines the “irradiance” reaching the substrate. Irradiance is the intensity of the light at the surface.

For LED systems, the light is usually non-focused. You should place the LED head as close to the substrate as possible, typically between 5mm and 10mm. If the gap is too wide, the light scatters. This reduces the energy density and leads to incomplete curing.

For mercury lamps, the bulb sits inside a parabolic or elliptic reflector. This reflector focuses the light into a high-intensity “stripe.” You must position the web exactly at this focal point. An incorrectly positioned lamp results in wasted energy and wet ink, even if the lamp is running at 100% power.

Speed Synchronization and Power Control

VDP jobs often vary in speed. The press might slow down for complex data processing or ramp up for simple serial numbering. Your UV system must be “slave” to the press speed.

Modern UV controllers use an encoder signal from the press. As the web speed increases, the controller automatically boosts the lamp power. If the press stops, the UV LED should turn off instantly. This prevents the web from burning or melting.

For high-speed narrow-web applications, look for systems that offer “proportional power control.” This ensures the “dose” (total energy delivered) remains constant regardless of the meters-per-minute rate.

Surface Tension and Adhesion

Variable data often involves printing on top of pre-printed flexo inks or coatings. This brings up the challenge of surface energy. If the base layer has a low dyne level, the VDP inkjet ink will “bead up” or crawl. This destroys the legibility of barcodes.

Test your substrate with dyne pens before starting the run. Most UV inkjet inks require a surface tension of at least 38 to 42 dynes. If the level is too low, consider adding a corona treater before the VDP station. Alternatively, use a “prime coat” that is compatible with both the flexo base and the digital top layer.

Heat Management on Narrow-Web Presses

Narrow-web printing often uses heat-sensitive materials like PE, PP, and BOPP. Excessive heat causes these films to stretch. This ruins the registration between the flexo colors and the VDP data.

UV LED is the superior choice here. LEDs emit almost no infrared radiation. The substrate stays cool. If you must use mercury lamps, ensure your cooling fans and water-cooling systems are functioning perfectly. Monitor the temperature of the web as it exits the curing station. If the film feels hot to the touch, you are likely over-curing or using unnecessary power.

Oxygen Inhibition in Thin Film VDP

Oxygen in the air can interfere with the curing process, especially in free-radical UV inks. This is called “oxygen inhibition.” It often results in a greasy or sticky surface layer, even if the ink underneath is hard.

This is a common problem with very thin ink layers used in high-resolution VDP. Some high-end setups use nitrogen purging. By flooding the curing zone with nitrogen, you displace the oxygen. This allows for a much faster and more complete cure with less UV energy. While nitrogen systems add cost, they are sometimes necessary for food-grade label applications where low migration is mandatory.

Validation and Quality Control

How do you know the VDP data is cured? You cannot rely on visual inspection alone. Use these three standard tests:

- The Tape Test: Apply a high-tack tape to the cured VDP area. Rip it off quickly. If any ink transfers to the tape, the cure is insufficient.

- The Thumb Twist: Press your thumb firmly into the print and twist. If the ink smudges or moves, the “through-cure” is failing.

- The Solvent Rub Test: Use a cotton swab soaked in Isopropyl Alcohol (IPA) or Methyl Ethyl Ketone (MEK). Rub the print with consistent pressure. Count the number of rubs until the ink wears through. Establish a “pass” number based on your customer’s requirements.

Digital microscopes are also helpful for VDP. Check the edges of the variable characters. If the edges look “fuzzy,” the ink might be spreading before it hits the UV light. This suggests you need to move the curing lamp closer to the inkjet printhead.

Maintenance for Longevity

UV systems are “set and forget” until they fail. To avoid downtime during critical VDP runs, follow a strict maintenance schedule.

For LED systems, keep the outer glass or quartz lens clean. Ink mist from the VDP heads can settle on the lens. This blocks the UV light. Clean it daily with a lint-free cloth and approved solvent.

For mercury systems, track the bulb hours. Mercury bulbs lose intensity over time, even if they still look bright. Replace them according to the manufacturer’s recommendations. Check the reflectors for any signs of dulling or warping. A dirty reflector can reduce UV output by 50% or more.

Integrating the System for Future Scalability

The label market is shifting toward more personalization. Your UV setup should be modular. If you start with a single VDP station for black text, choose a power supply that can handle additional lamps if you later add full-color digital units.

By focusing on wavelength matching, heat management, and precise mechanical alignment, you ensure your variable data is as durable as the rest of the label. This technical approach reduces waste and keeps your narrow-web operation competitive in a digital-first market.