High-speed narrow web flexo printing demands absolute control over ink behavior. When running multi-color jobs on filmic substrates or high-gloss papers, ink droplets tend to spread or bleed before they reach the final curing station. This phenomenon, often called “image bleed” or “dot gain escalation,” compromises print clarity. LED UV pinning offers a technical solution to stabilize these droplets between print stations. This tutorial examines the mechanics, integration, and process advantages of implementing LED UV pinning in modern flexo and offset environments.

Understanding the Mechanics of UV Pinning

UV pinning is not a full cure. It is a process of partial polymerization where the ink is exposed to a low dose of UV energy immediately after it hits the substrate. This exposure increases the viscosity of the ink, transforming it from a liquid to a “gel-like” state. By “freezing” the dot in place, the ink loses its ability to flow or spread.

In a multi-color flexo press, pinning lamps sit between individual print stations. As the substrate moves at high speeds, each color is stabilized before the next color is applied. This prevents the “wet-on-wet” mixing that often leads to muddy colors or loss of detail in highlight areas. The final full cure still happens at the end of the press, but the internal structure of the print remains crisp because of the inter-station pinning.

LED Technology vs. Traditional Mercury Lamps

Traditional mercury vapor lamps generate significant infrared heat. In narrow web label printing, heat is the enemy of thin, heat-sensitive films like PE or shrink PVC. Mercury lamps also require shutters and warm-up times, making them inefficient for inter-station use where space is limited.

LED UV systems provide a monochromatic output, typically at 385nm or 395nm. This specific wavelength penetrates the ink layer effectively without heating the substrate. The instant on/off capability of LED allows for precise control. Engineers can sync the lamp intensity with the press speed, ensuring consistent energy delivery regardless of whether the press is ramping up or running at full production speed.

Optimizing Dot Gain and Color Trapping

Dot gain is an inherent challenge in flexo printing. The pressure of the plate against the substrate naturally flattens the ink. Without pinning, the ink continues to spread after the impression. LED UV pinning arrests this movement instantly.

For multi-color work, “trapping” is the ability of one ink layer to accept another on top of it. If the first layer is too liquid, the colors mix and blur. If the first layer is fully cured (over-cured), the second layer will not adhere properly, leading to flaking. Pinning creates the perfect “tacky” surface. It provides enough structural integrity to hold the dot shape while remaining chemically active enough to bond with the subsequent ink layer. This balance is vital for achieving high-density solids and sharp screened images simultaneously.

Technical Integration in Narrow Web Presses

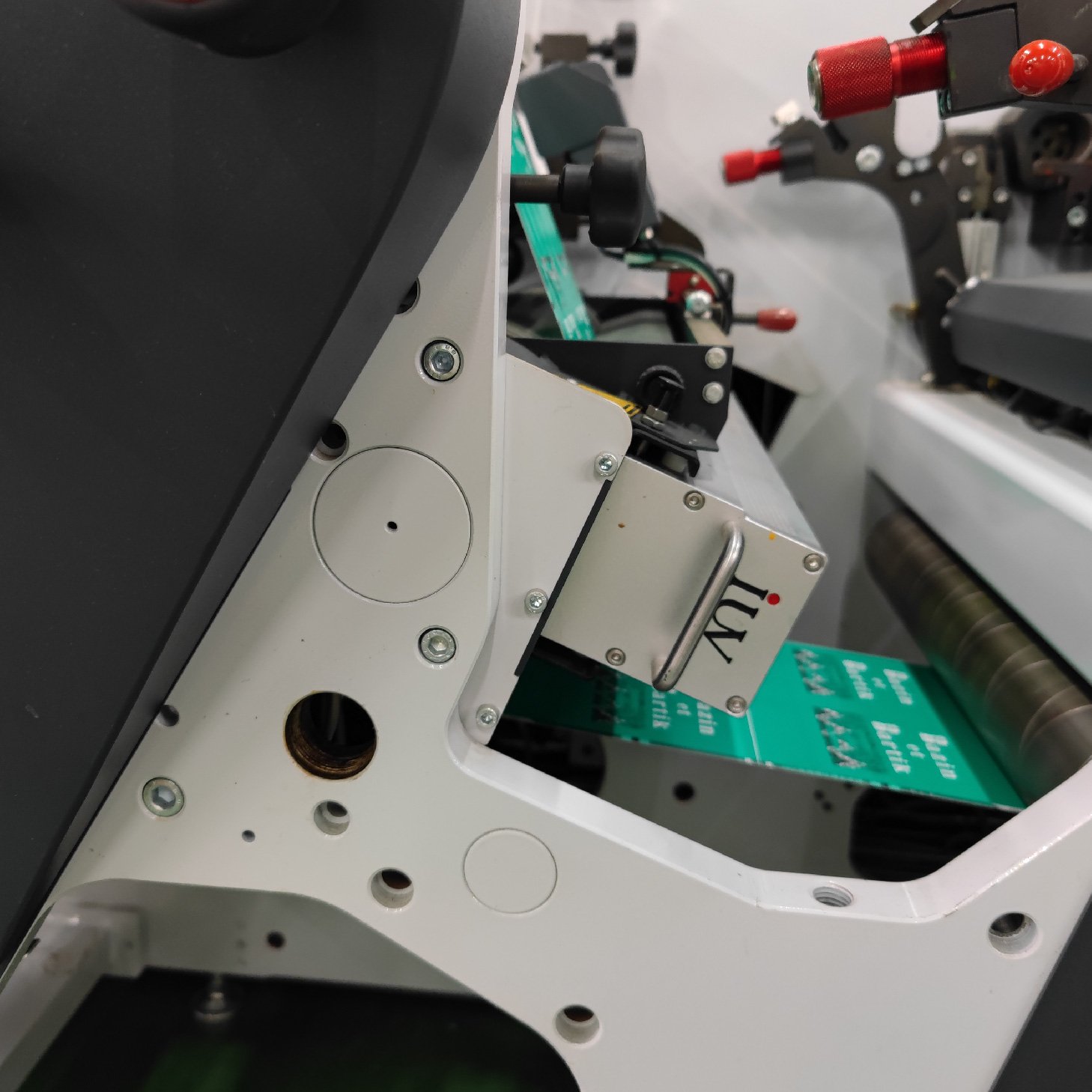

Integrating LED pinning into a narrow web press requires careful mechanical positioning. The lamp head must be compact enough to fit between the print cylinder and the next color station. Usually, a distance of 10mm to 20mm from the substrate is optimal for maximizing irradiance.

The irradiance (measured in W/cm²) determines how quickly the “skin” of the ink forms. For pinning, we generally look for lower dosage (mJ/cm²) compared to full curing. If the dosage is too high, the ink surface hardens too much, causing inter-coat adhesion failure. Engineers must calibrate the power output based on the specific ink chemistry and the opacity of the pigments. Black and opaque white inks, for instance, require slightly more intensity due to their UV-absorbing properties.

Ink Chemistry and Photoinitiator Response

LED UV pinning works because of specialized photoinitiators within the ink. These chemicals react specifically to the long-wave UV-A output of LED chips. In a standard UV ink, the photoinitiators are tuned for the broad spectrum of a mercury lamp. For successful pinning, the ink supplier must ensure the formulation matches the 395nm peak of the LED lamp.

When the LED light hits the ink, a free-radical polymerization starts. Because the pinning dose is low, only a fraction of the monomers are converted into polymers. This creates a high-viscosity matrix. This matrix holds the pigments in place but leaves enough unreacted acrylate groups for the final curing station to complete the molecular cross-linking.

Impact on Label and Packaging Production

In the label industry, visual pop and fine text are benchmarks of quality. LED UV pinning allows converters to use higher-strength inks with lower film weights. Because the dot does not spread, you can achieve higher optical density without the risk of “filling in” small reverse text or fine screens.

For offset printing applications on plastic cards or specialized labels, pinning prevents “set-off.” Set-off occurs when wet ink transfers to the backside of the next sheet or the next layer of the roll. By pinning the ink, the sheet becomes handleable almost immediately, significantly reducing waste during high-speed transitions.

Heat Management and Substrate Stability

One of the most significant advantages of LED pinning is the reduction of thermal stress on the substrate. In multi-color printing, passing under four or five mercury lamps would cause thin films to stretch or warp. This makes registration (the alignment of colors) nearly impossible to maintain.

LED lamps are “cold” sources. While the LED chip itself generates heat, it is managed through water-cooling or air-cooling systems on the back of the lamp head. No infrared radiation is directed at the web. This stability allows for the use of thinner, more economical films, which reduces material costs and improves the environmental footprint of the production run.

Troubleshooting Common Pinning Issues

While LED pinning simplifies many aspects of printing, it requires precise calibration. A common issue is “over-pinning.” If the inter-station lamps are set to 100% power, the ink surface becomes too smooth and chemically inert. The next ink station will “bead up” on the surface, a defect known as crawling.

Conversely, “under-pinning” occurs when the intensity is insufficient to stop ink migration. This usually happens if the lamp windows are dirty or if the press speed has exceeded the lamp’s dosage capacity. Regular maintenance of the LED protective glass and the use of integrated UV sensors can prevent these shifts in quality.

Enhanced Productivity and Press Speed

Traditional UV systems often act as a bottleneck. If the lamps cannot cure fast enough, the press speed must be reduced. LED UV pinning removes this limitation by sharing the curing load. By starting the polymerization process early, the final curing station doesn’t have to do all the work.

This distributed energy approach allows presses to run at speeds exceeding 200 meters per minute while maintaining premium print quality. Furthermore, the lack of ozone production from LED lamps eliminates the need for complex extraction ducting, simplifying the pressroom environment and reducing energy consumption by up to 50% compared to conventional UV setups.

Future-Proofing the Flexo Process

The transition to LED UV pinning is a strategic move for narrow web converters. As brand owners demand higher resolutions and more complex designs on difficult substrates, the ability to control ink rheology at every step is essential.

The technical synergy between LED hardware and modern ink chemistry provides a stable, repeatable process. By mastering the variables of irradiance, wavelength, and mechanical placement, engineers can ensure that multi-color flexo printing remains competitive against digital alternatives. The precision offered by pinning technology ensures that every dot placed on the substrate remains exactly where it was intended, resulting in the sharpest possible image in the narrow web industry.