In the dynamic world of label printing, staying ahead means embracing innovation. One of the most significant advancements in recent years is the integration of LED UV curing technology. This powerful method offers a host of advantages, from faster drying times to enhanced print quality and reduced environmental impact. For narrow web, flexographic, and offset label printers, understanding how to best incorporate LED UV curing can unlock new levels of efficiency and profitability.

The Power of LED UV Curing in Label Production

Traditional UV curing systems have long been a staple in the printing industry. However, LED UV curing represents a leap forward. Unlike conventional mercury lamps, LED systems emit a more focused spectrum of UV light. This targeted emission means less wasted energy and a more efficient curing process. For label applications, this translates to sharper images, vibrant colors, and durable finishes that can withstand challenging environments.

The benefits extend to operational efficiency. LED UV lamps reach full intensity almost instantly, eliminating the warm-up time associated with mercury lamps. This immediate on-demand capability is particularly valuable in high-speed narrow web printing environments where every second counts. Furthermore, LED UV systems generate significantly less heat, which is a crucial consideration when printing on heat-sensitive substrates commonly used for labels, such as certain plastics and foils.

Seamless Integration into Your Workflow

Integrating LED UV curing into your existing label printing workflow requires careful planning. The process involves understanding your current setup and identifying the most suitable points for conversion.

For Flexographic Printing

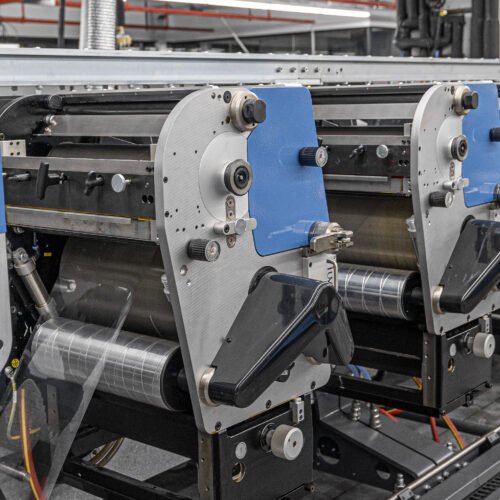

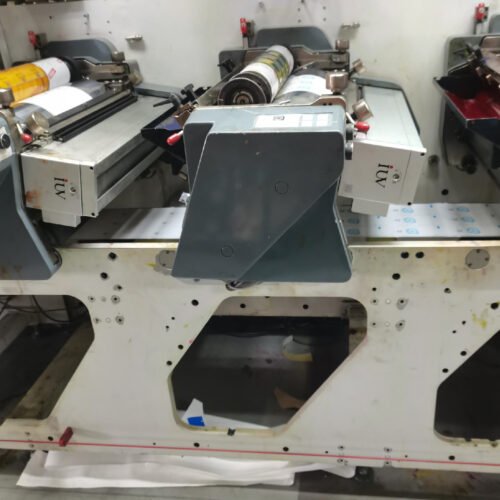

Flexographic printing is a dominant force in narrow web label production. Integrating LED UV curing in flexo can dramatically improve throughput. The quick curing nature of LED UV allows for faster press speeds, enabling printers to meet demanding production schedules. When moving from conventional UV or IR drying, consider the following:

- Ink and Coating Compatibility: Ensure your flexographic inks and coatings are specifically formulated for LED UV curing. While many traditional UV inks can be adapted, dedicated LED UV formulations often provide superior performance and faster cure speeds. Work closely with your ink suppliers to select the right products.

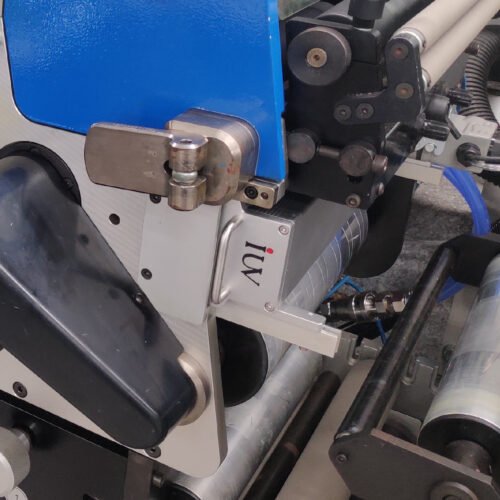

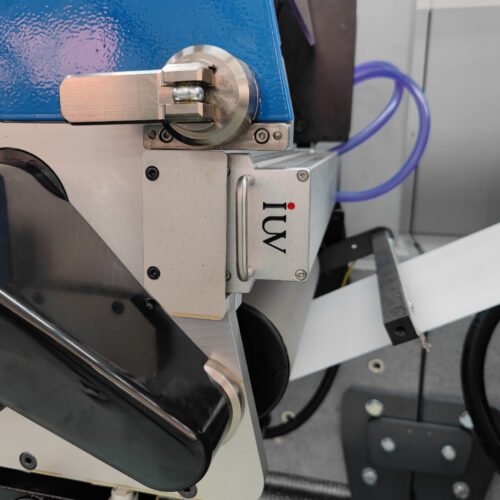

- Press Modifications: Depending on your press age and configuration, you may need modifications to accommodate LED UV curing units. This typically involves installing the LED lamps between printing stations or at the end of the press. Considerations include proper ventilation, power supply, and mounting.

- Substrate Considerations: The reduced heat output of LED UV is a significant advantage for sensitive flexo substrates. This opens up possibilities for printing on a wider range of materials without risking distortion or damage.

For Offset Printing

Sheetfed and web offset printing also benefit from LED UV technology, especially in the label sector where high-quality graphics are paramount. Offset printers can achieve instant drying of inks and coatings, enabling immediate finishing operations and reducing the need for special anti-set-off powders.

- Ink Formulation: As with flexo, using offset inks specifically designed for LED UV curing is key. These inks are formulated to react rapidly to the specific wavelengths emitted by LED lamps, ensuring a complete and robust cure.

- Press Integration: Offset presses often require retrofitting or the purchase of new units equipped with LED UV dryers. These are typically placed after the last printing unit. The compact nature of LED UV systems can sometimes make integration simpler than with older, bulkier UV dryers.

- Handling and Finishing: The instantaneous cure means labels can be handled, stacked, or sent to finishing processes like die-cutting or embossing immediately after printing. This eliminates waiting times and reduces the risk of smudging or scratching.

Narrow Web Printing Specifics

Narrow web printing, often associated with flexography, is where LED UV curing truly shines. The high speeds and continuous production common in this segment make the efficiency gains of LED UV particularly impactful.

- Inline Curing: The most effective integration is often achieved with inline LED UV curing units positioned between printing stations. This allows for wet-on-wet printing of multiple colors with a full cure after each station or a final cure at the end of the press. This capability is invaluable for creating complex, multi-layer label designs.

- Energy Efficiency: Compared to traditional UV, LED UV systems consume significantly less energy. This translates to lower operating costs, a vital factor for label printers operating on tight margins. The longer lifespan of LED lamps also reduces maintenance and replacement expenses.

- Reduced VOCs: LED UV curing, when used with appropriate inks, can help reduce or eliminate Volatile Organic Compounds (VOCs) compared to some conventional drying methods. This contributes to a healthier working environment and helps printers meet stricter environmental regulations.

Key Considerations for Success

Beyond the technical integration, several strategic considerations will ensure a smooth transition and maximize the benefits of LED UV curing.

Understanding UV Curing Principles

While LED UV is advanced, a foundational understanding of UV curing principles is beneficial. UV curing relies on photoinitiators within the ink or coating that absorb UV light. This absorption triggers a chemical reaction, causing the ink or coating to polymerize and solidify almost instantly. LED UV lamps emit specific wavelengths that are highly efficient at activating these photoinitiators, leading to a rapid and thorough cure.

- Wavelength Matching: Different LED UV lamps emit light at specific wavelengths (e.g., 365nm, 385nm, 395nm, 405nm). It’s critical to match the lamp’s wavelength to the photoinitiators present in your inks and coatings for optimal curing. Your ink supplier will be the best resource for this information.

- Irradiance and Energy Dose: The intensity of the UV light (irradiance, measured in W/cm²) and the total energy delivered (dose, measured in J/cm²) are crucial for a complete cure. LED systems allow for precise control over these parameters, ensuring consistent results.

Substrate Flexibility

One of the most compelling advantages of LED UV curing is its ability to handle a wide range of substrates without excessive heat. This is particularly relevant for label printing, where materials like thin films, foils, and even some recycled papers can be challenging for high-heat drying methods. The low thermal output of LED UV prevents distortion, shrinkage, or degradation of these delicate materials, expanding your printing capabilities and material options.

Ink and Coating Selection

The success of your LED UV integration hinges on selecting the right inks and coatings. Modern formulations are specifically engineered to work with LED UV technology, offering enhanced adhesion, scratch resistance, and chemical resistance.

- Performance Characteristics: Discuss your specific label application requirements with your ink supplier. Do you need high rub resistance for a product that will be handled frequently? Is chemical resistance necessary for labels on cleaning products? LED UV formulations can be tailored to meet these demands.

- Color Gamut and Brightness: LED UV cured inks often exhibit exceptional vibrancy and color saturation. This can lead to more eye-catching labels that stand out on the shelf.

Operational Adjustments

Adapting your operational procedures is as important as the technical setup.

- Training: Ensure your press operators are adequately trained on the new technology. This includes understanding the specifics of LED UV curing, proper machine operation, and troubleshooting common issues.

- Maintenance: While LED UV lamps have a longer lifespan than traditional UV lamps, they still require maintenance. This includes keeping the lamps clean and ensuring proper ventilation. Consult the manufacturer’s guidelines for specific maintenance schedules.

- Quality Control: Establish robust quality control procedures to monitor the cure of your labels. This might involve rub tests, adhesion tests, and visual inspection for any signs of uncured ink or coating.

The Future of Label Printing is Here

The integration of LED UV curing technology into label printing workflows represents a significant step forward for the industry. For flexographic, offset, and narrow web printers, embracing this technology offers a pathway to improved efficiency, enhanced print quality, greater substrate flexibility, and a more sustainable operation. By understanding the principles, planning the integration carefully, and selecting the right partners and materials, you can successfully leverage LED UV curing to elevate your label printing business and stay competitive in a rapidly evolving market.