The printing industry is constantly evolving, driven by the need for faster production, higher quality, and greater efficiency. In the realm of label printing, particularly within narrow web applications like flexographic and offset printing, the adoption of LED UV curing technology represents a significant leap forward. This advanced curing method is fundamentally reshaping how label printers achieve speed and maintain exceptional output quality.

Understanding UV Curing Technologies

Before delving into the specifics of LED UV, it’s helpful to understand traditional UV curing. This process uses ultraviolet light to initiate a photochemical reaction, instantly drying (or “curing”) inks, coatings, and adhesives. Traditional UV lamps, often mercury vapor lamps, have been the standard for decades. However, they come with certain limitations: high energy consumption, significant heat generation, a limited lifespan, and the need for frequent replacement.

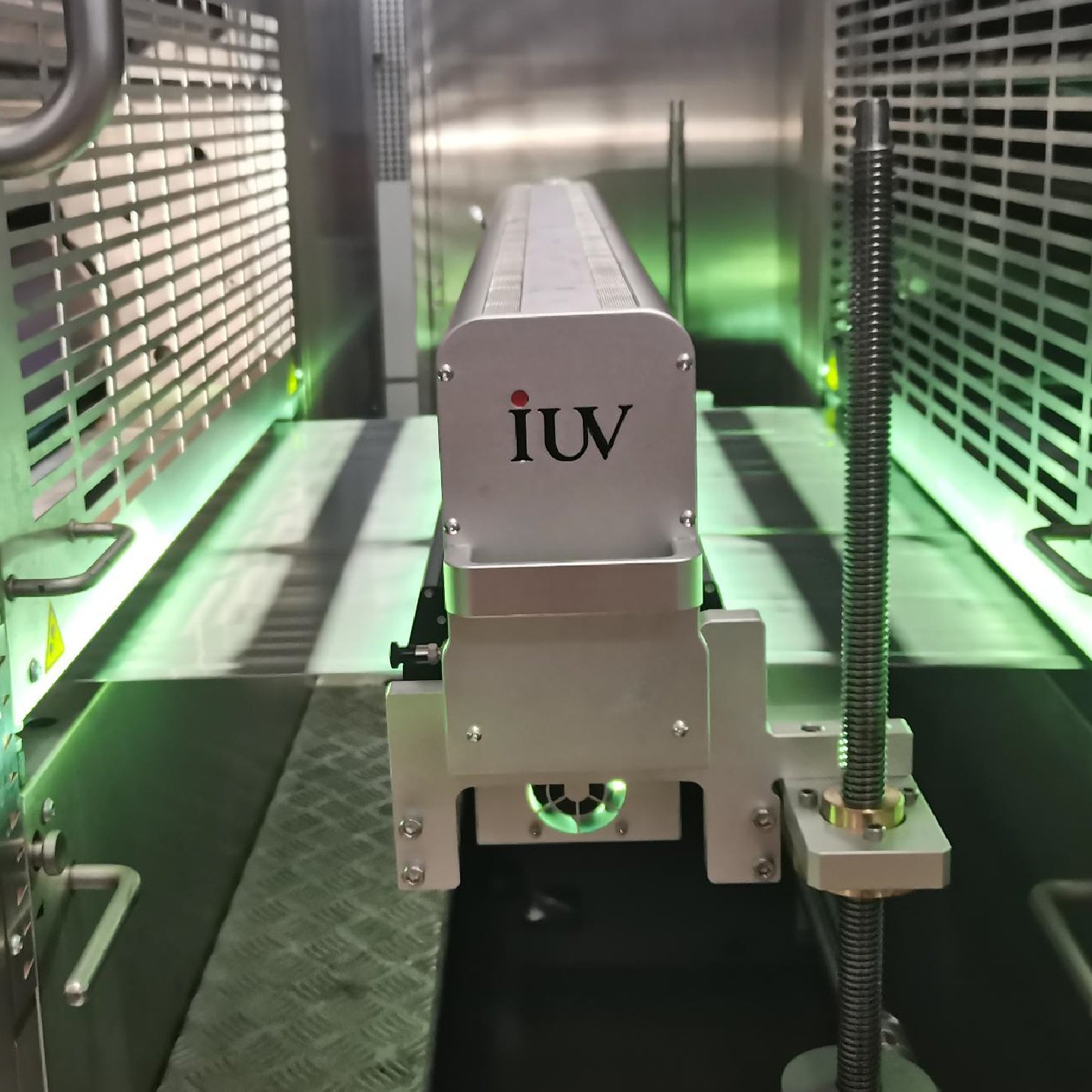

The Rise of LED UV Curing

LED (Light Emitting Diode) UV curing technology utilizes solid-state light sources that emit UV light at specific wavelengths. This targeted emission is a game-changer. Unlike broadband mercury lamps, LEDs offer a focused spectral output, ensuring more efficient and consistent curing of UV-curable inks and coatings.

Enhancing Print Speed with LED UV

One of the most compelling advantages of LED UV curing in label presses is its direct impact on print speed. Traditional UV lamps often require a balance between curing intensity and ink laydown, sometimes limiting the maximum press speed to avoid incomplete curing or ink misting.

LED UV systems, with their high-intensity, focused UV output, can cure inks much faster and more effectively. This allows label printers to:

- Run Presses at Higher Speeds: The instantaneous and thorough curing enabled by LEDs means presses can operate at their maximum mechanical speeds without compromising ink adhesion or finish. This translates directly into higher production volumes within the same timeframe.

- Reduce Inter-Color Station Drying Times: In multi-color printing processes common in flexographic and offset label production, each color station needs to be dried before the next color is applied. LED UV’s rapid curing significantly reduces the dwell time required between stations, enabling a more streamlined and faster overall print process.

- Minimize Downtime for Lamp Replacement: Traditional UV lamps have a finite lifespan and can degrade over time, requiring more frequent maintenance and replacement. LEDs, with their extended operational life (often tens of thousands of hours), drastically reduce the frequency of lamp changes, minimizing press downtime and associated labor costs.

Elevating Output Quality with LED UV

Beyond speed, LED UV curing plays a pivotal role in enhancing the overall quality of printed labels. The precise control and consistent output of LED systems contribute to superior results across various aspects of label production.

- Improved Ink Adhesion and Durability: The efficient and complete curing provided by LEDs ensures that inks bond strongly to the substrate. This results in labels that are more resistant to scuffing, scratching, and chemical exposure, crucial for products that undergo harsh handling or environmental conditions.

- Sharper Dot Definition and Text Clarity: LED UV systems cure inks from the surface downwards. This prevents excessive spreading or “dot gain,” leading to sharper printed images, crisp text, and finer graphic details. This is particularly important for high-resolution graphics and small text common on pharmaceutical, cosmetic, and premium product labels.

- Vibrant and Consistent Color Reproduction: The targeted wavelengths emitted by LEDs ensure that photoinitiators in the ink are activated efficiently and consistently. This leads to more vibrant colors and greater color consistency across long print runs, reducing the need for color adjustments and waste.

- Reduced Heat on Substrates: Traditional UV lamps generate substantial heat, which can cause issues with heat-sensitive substrates like thin films or some paper stocks. This can lead to substrate shrinkage, distortion, or even scorching. LED UV systems emit very little infrared heat, allowing for the printing of a wider range of materials without compromising their integrity. This opens up new possibilities for label design and application.

- Wider Ink and Coating Compatibility: While traditional UV curing systems can be limited in their compatibility with certain ink formulations, LED UV technology, with its tunable wavelengths, offers greater flexibility. Printers can utilize a broader spectrum of LED-curable inks and coatings, including low-migration options essential for food packaging, enhancing both performance and safety.

LED UV in Different Label Printing Processes

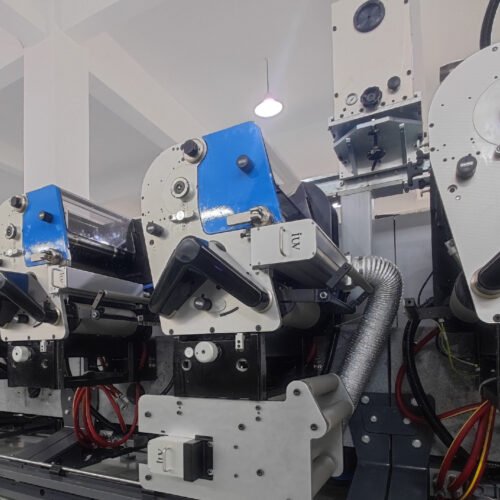

The benefits of LED UV curing are not confined to a single printing method. Its impact is significant across the major narrow web label printing technologies:

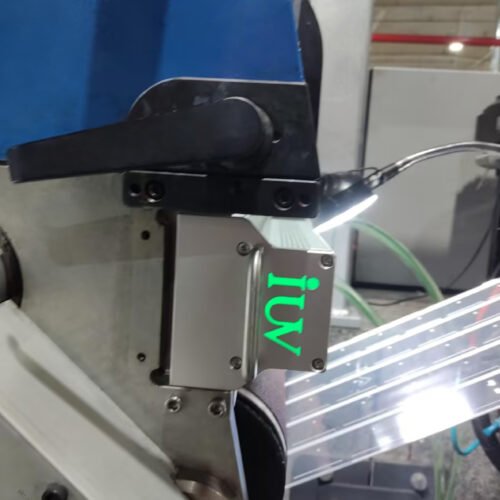

- Flexographic Printing: Flexo is a dominant force in narrow web label printing. LED UV curing enhances flexo by allowing for faster press speeds, crisper dot reproduction essential for fine details in packaging, and improved ink transfer. The reduced heat is also advantageous for the rubber or photopolymer plates commonly used.

- Offset Printing (Sheetfed and Web): While less common in ultra-narrow web applications than flexo, offset printing for labels also benefits. LED UV allows for faster drying of inks, reducing the risk of set-off and enabling immediate finishing operations. This is especially true for sheetfed offset labels that are then die-cut.

- Digital Printing: While not directly a “curing” technology in the same sense as UV, UV-curable inks are widely used in inkjet digital label presses. LED curing is the standard here, enabling instant drying of inkjet droplets on a wide array of substrates, facilitating high-speed, on-demand label production.

Challenges and Considerations

While the advantages are clear, implementing LED UV curing also presents considerations:

- Initial Investment: The upfront cost of LED UV curing systems can be higher than traditional mercury lamps. However, the long-term savings in energy, consumables, and increased productivity often justify this investment.

- Ink Formulation: Not all existing UV-curable inks are optimized for LED curing. Printers may need to transition to inks specifically formulated with LED-compatible photoinitiators to achieve optimal results.

- Wavelength Specificity: Different LED systems emit UV light at specific wavelengths (e.g., 365nm, 385nm, 395nm, 405nm). It’s important to match the LED wavelength to the photoinitiators in the ink or coating for maximum curing efficiency.

The Future of Label Printing

The integration of LED UV curing technology is more than just an upgrade; it’s a fundamental shift towards more efficient, sustainable, and high-quality label production. As the technology matures and costs continue to decrease, its adoption in narrow web presses for flexographic, offset, and digital printing will undoubtedly accelerate.

For label printers looking to gain a competitive edge, enhance their product offerings, and improve their bottom line, embracing LED UV curing is a strategic imperative. It’s a clear pathway to achieving higher print speeds, superior output quality, and a more sustainable manufacturing process in the dynamic world of label printing.