The landscape of narrow web printing is continually evolving, driven by demands for faster turnaround times, enhanced print quality, and greater sustainability. At the forefront of this evolution is UV curing technology, and specifically, the advent of LED UV curing systems. This review delves into the significant advantages and considerations of implementing LED UV curing within narrow web printing environments, including applications in label, flexographic, and offset printing.

The Rise of UV Curing in Narrow Web Printing

For decades, traditional thermal curing and mercury vapor UV lamps have been the workhorses for drying inks and coatings in narrow web presses. However, these older technologies come with inherent drawbacks. Thermal curing requires significant energy consumption and can lead to substrate distortion, especially with heat-sensitive materials. Mercury vapor lamps, while effective, generate substantial heat, consume considerable power, and contain hazardous materials that require careful disposal.

UV curing, as a process, utilizes ultraviolet light to instantly polymerize or “cure” inks, coatings, and adhesives. This rapid curing process offers a host of benefits for narrow web applications:

- Instant Drying: Eliminates the need for long drying tunnels, allowing for faster press speeds.

- Versatile Substrates: Enables printing on a wider range of materials, including plastics and foils, that cannot withstand high temperatures.

- Enhanced Durability: Cured inks and coatings offer superior scratch resistance, chemical resistance, and color vibrancy.

- Reduced VOCs: UV inks are typically solvent-free or contain very low levels of Volatile Organic Compounds (VOCs), contributing to a healthier working environment and reduced environmental impact.

Transitioning to LED UV Curing: A Smart Investment

LED (Light Emitting Diode) UV curing represents a significant advancement over traditional mercury lamp systems. Instead of a broad spectrum of UV light, LEDs emit specific wavelengths, typically in the UV-A range. This targeted approach unlocks a new level of efficiency and performance for narrow web printers.

Key Advantages of LED UV Curing Systems

The benefits of adopting LED UV curing for narrow web presses are compelling and multifaceted:

- Exceptional Energy Efficiency: LED systems consume significantly less energy than mercury lamps. They only use power when actively curing, whereas mercury lamps remain hot even when not in use. This translates directly into lower operating costs.

- Longer Lifespan: LED lamps boast an impressive operational lifespan, often exceeding 20,000 to 50,000 hours. This dramatically reduces downtime associated with lamp replacements and associated maintenance costs.

- Instant On/Off Capability: LEDs achieve full curing intensity immediately upon activation and shut off instantly. This “instant on/off” capability is perfect for intermittent printing applications and prevents unnecessary energy waste.

- Low Heat Emission: LEDs generate far less heat compared to mercury lamps. This is crucial for printing on sensitive substrates like thin films and delicate papers, preventing warping or dimensional instability.

- Focused Wavelengths: LEDs emit specific UV wavelengths that are precisely matched to the photoinitiators in UV inks and coatings. This precise match ensures efficient and thorough curing with less wasted energy.

- Mercury-Free Technology: LED systems are free from hazardous mercury, simplifying disposal and contributing to a safer workplace and a more environmentally conscious printing process.

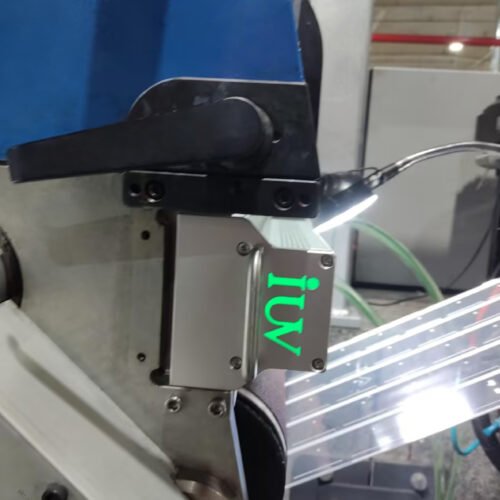

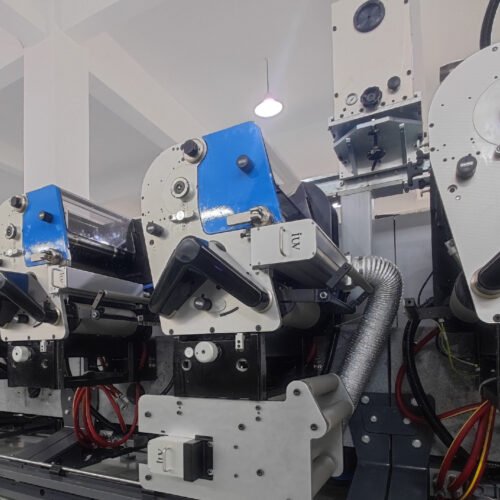

- Compact Design: The compact nature of LED arrays allows for easier integration into existing narrow web press configurations, often requiring less space than older curing units.

- Consistent Output: LEDs provide stable and consistent UV output throughout their lifespan, ensuring reliable curing performance and predictable print quality over time.

LED UV Curing in Specific Narrow Web Applications

The versatility of LED UV curing makes it an ideal solution across various narrow web printing technologies:

LED UV in Label Printing

The label printing industry is a prime candidate for LED UV curing. Whether employing flexographic or offset printing methods, labels often require vibrant colors, durable finishes, and the ability to print on a wide array of materials.

- Flexographic Label Printing: In flexo, LED UV curing ensures rapid ink solidification, allowing for higher press speeds and sharper dot reproduction. This is particularly beneficial for intricate designs and fine text found on many labels. The low heat output is also advantageous when working with thin film label stocks.

- Offset Label Printing: For offset label printers, LED UV systems provide a clean and efficient curing solution, eliminating the need for powders that can interfere with subsequent finishing processes. The consistent curing output contributes to repeatable color fidelity, a critical factor in brand packaging.

LED UV in Flexographic Printing (Beyond Labels)

Flexographic printing extends beyond labels to include packaging, flexible films, and other flexible materials. In these applications, LED UV curing offers:

- Enhanced Barrier Properties: Cured UV coatings can impart excellent barrier properties against moisture and oxygen, crucial for food and pharmaceutical packaging.

- High-Gloss Finishes: LED UV systems can achieve superior high-gloss finishes, adding aesthetic appeal to printed products.

- Durable Overprint Varnishes: Applying UV overprint varnishes with LED curing provides robust protection against abrasion and scuffing, extending the shelf life and visual appeal of the printed item.

LED UV in Offset Printing (Narrow Web)

Narrow web offset printing, often used for high-volume, high-quality label and packaging runs, benefits immensely from LED UV technology.

- Reduced Paper Dust: The elimination of anti-set-off powders is a significant advantage, leading to cleaner print runs and fewer issues with post-press operations like die-cutting and hot foiling.

- Process Simplification: LED UV curing simplifies the entire printing process by removing the need for lengthy drying times or intermediate cooling stages.

- Vibrant Color Reproduction: The precise curing mechanism ensures that ink colors remain true and vibrant, contributing to premium brand presentation.

Considerations for Implementing LED UV Curing

While the benefits of LED UV curing are substantial, a thoughtful approach to implementation is key.

Ink and Coating Compatibility

Not all UV inks and coatings are formulated for LED curing. It’s imperative to select inks and coatings that are specifically designed to cure effectively under the specific wavelengths emitted by the chosen LED system. These inks contain photoinitiators that are highly responsive to the narrow spectrum of LED light.

Wavelength and Irradiance

LED UV systems offer various wavelength options (e.g., 365 nm, 385 nm, 395 nm, 405 nm). The optimal wavelength depends on the photoinitiators in your inks and coatings. Irradiance, measured in Watts per square centimeter (W/cm²), refers to the intensity of the UV light. Higher irradiance generally leads to faster curing. Matching the LED system’s wavelength and irradiance to your ink requirements is critical for achieving optimal cure.

Press Integration and Cooling

While LEDs generate less heat than mercury lamps, proper ventilation and cooling systems are still important, especially for high-speed presses. Ensuring adequate airflow around the LED curing units will help maintain optimal operating temperatures for both the LEDs and the press. The physical integration of the LED units into the press architecture also needs careful planning.

Cost and Return on Investment (ROI)

The initial investment in LED UV curing systems can be higher than traditional systems. However, when factoring in the long-term savings from reduced energy consumption, lower lamp replacement costs, increased press uptime, and the ability to print on a wider range of jobs, the ROI is often compelling and can be realized relatively quickly.

The Future is Bright with LED UV Curing

LED UV curing technology has rapidly moved from a niche solution to a mainstream necessity for modern narrow web printing operations. Its inherent efficiency, environmental advantages, and ability to enhance print quality make it an indispensable tool for label printers, flexographers, and offset printers alike. By embracing this advanced technology, businesses can unlock new levels of productivity, profitability, and sustainability in their operations. The focused power and precise control offered by LED UV systems are illuminating the path forward for the entire narrow web printing industry.