High-resolution label production demands precise color, sharp detail, and reliable adhesion. LED UV curing systems have become a preferred solution for many narrow-web converters. This review examines their performance specifically for label tasks across flexo, offset (plate) and narrow-web presses. The focus is on cure quality, press integration, ink chemistry, and real-world productivity.

Why LED UV Is Suited to Label Work

LED UV lamps deliver near-instant on/off curing with consistent spectral output. Labels often run on heat-sensitive films and thin papers. Lower radiant heat from LEDs reduces substrate deformation and edge waviness. Narrow-web lines particularly benefit from compact LED modules that fit into tight press frames. Shorter warm-up cycles enable faster job changeovers and less downtime.

How LED UV Curing Works

LED arrays emit narrow-band ultraviolet light, commonly centered at 365, 385, 395, or 405 nanometers. Photoinitiators in the ink absorb that energy and trigger polymerization. Cure depends on three factors: spectral match between LEDs and photoinitiator, irradiance (power density), and dose (irradiance over exposure time). All three must align for consistent surface and through-cure.

Advantages for Flexo Label Printing

Flexographic label inks are formulated to cure quickly with limited energy. LED UV systems provide uniform spot curing across anilox patterns and fine halftones. The low heat profile protects plates, sleeves, and thin liners. Many presses see improved dot gain control and crisper edges. For water-based or solventless systems that rely on UV overprint varnishes, LED units offer better gloss control and reduced tack.

Impact on Offset and Plate-Based Label Jobs

Offset label printing often uses conventional UV inks with broad photoinitiator blends. Some formulations optimize for mercury or arc lamps rather than LEDs. Successful conversion requires ink and varnish adaptation. By selecting LED-compatible inks and adjusting photoinitiator packages, offset presses achieve comparable cure speed and adhesion. Plate life and dampening systems remain stable under lower heat.

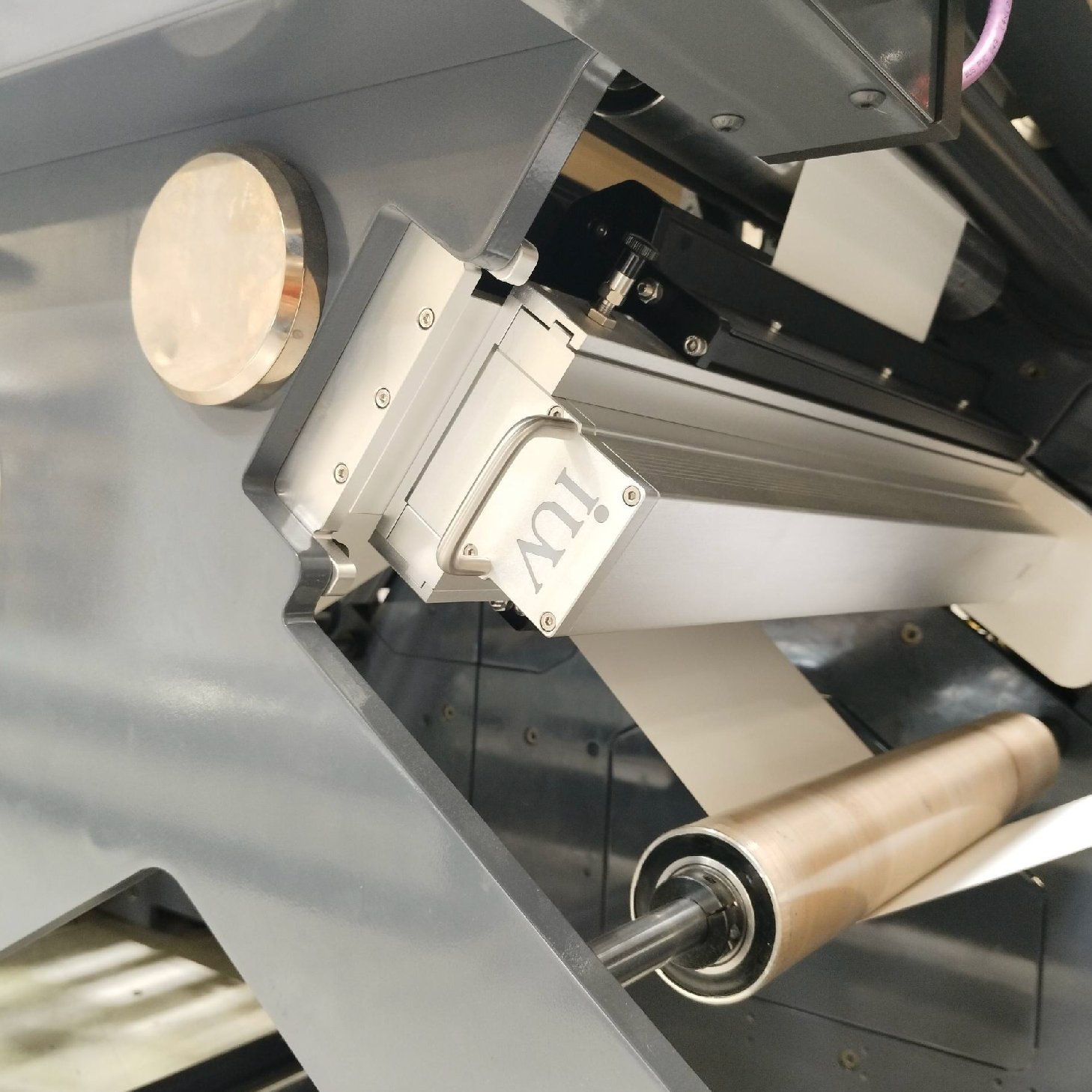

Narrow-Web Considerations

Narrow-web operations demand compact, modular curing heads. LED modules fit into the limited space without extensive press rebuilds. Cooling and airflow become critical because concentrated LED arrays create hot spots. Chilled rollers, optimized reflector geometry, and controlled air extraction ensure consistent substrate temperature. For shrink-sleeve or wraparound labels, even thermal distribution avoids distortion during subsequent processing.

Ink Chemistry and Photoinitiator Matching

Photoinitiator absorption peaks must align with LED emission. Many legacy inks use Type I and Type II photoinitiators that prefer 250–360 nm wavelengths. Modern LED-curable inks use redesigned photoinitiators tuned to 385–405 nm. Ask your ink supplier for LED-specific data and cure charts. Adhesion promoters, oligomer selection, and pigment packages also affect cure depth and final physical properties.

Key Performance Metrics

Measure output with a lab-grade spectroradiometer or calibrated radiometer. Track peak irradiance (mW/cm²) at the target wavelength and integrated dose (J/cm²) over the exposure window. For labels, surface tack, MEK resistance, and cross-hatch adhesion tests give practical quality indicators. High-resolution images require stable irradiance across the cured width to prevent banding or tonal shifts.

Heat Management and Substrate Handling

Despite lower UV-induced heat, LEDs generate localized thermal loads at the diode junction. Forced air cooling or liquid-cooled bars extends LED life and keeps reflectors stable. Control substrate temperature with chill drums or vacuum-assisted idlers. Maintain consistent web tension and minimize wrap angles near the cure zone. These steps preserve registration and prevent stretching of thin PET films.

Integration and Safety

LED modules are compact but require correct installation height and angle. Use adjustable stands, shuttering, and modular housings to tune exposure. Install interlocks and shielding to meet workplace safety standards. Unlike mercury lamps, LEDs do not emit significant ozone. Still, UV exposure protection for operators and light leakage controls remain essential.

Cure Monitoring and Process Control

Inline cure monitoring supports consistent label quality. Beam uniformity checks, inline spectrometers, and industrial cameras detect banding and uneven cure. Implement statistical process control for radiant output and dose. Integrate printer control systems to adjust web speed or multiple LED zones in real time. Routine tack testing after set intervals helps catch formulation drift or lamp aging.

Maintenance and Lifespan

LED arrays offer long service lives, often tens of thousands of operating hours. Expect gradual output decline rather than sudden failure. Keep optics clean and dust-free. Replace reflectors or lenses if scratched or discolored. Verify cooling fans and liquid circuits on regular service schedules. Proper upkeep reduces downtime and preserves consistent dot reproduction.

Economic and Environmental Benefits

LED curing reduces energy consumption and eliminates mercury disposal concerns. Faster job changes and instant on/off cycles improve press utilization. Less substrate scrap results from reduced heat-induced distortion. For converters pursuing sustainability claims, LED systems support lower lifecycle impacts and cleaner indoor air quality.

Common Challenges and Mitigation

Spectral mismatch can cause incomplete cure or poor adhesion. Run test swatches across intended substrates. Thicker ink layers and opaque whites may need multiple passes or higher dose. Edge-to-edge uniformity can suffer if modules are misaligned. Use calibrated radiometers to align banks and verify overlap zones. Work closely with ink and adhesive suppliers during conversion.

Selecting the Right System

Match the LED wavelength to your ink photoinitiator profile. Evaluate modular flexibility for future press upgrades. Confirm irradiance levels at production speeds and for the full range of substrates. Ask vendors for sample curing trials and independent performance data. Factor in service, spare parts availability, and integration support from the supplier.

Conclusion

LED UV curing has matured into a reliable solution for high-resolution label production. When spectral match, irradiance, and dose align with ink and substrate selection, results rival traditional mercury and arc systems. For flexo, offset, and narrow-web presses, LEDs offer faster make-ready, lower thermal impact, and improved sustainability. Successful adoption depends on careful testing, good process controls, and ongoing maintenance. With the right choices, converters can boost print quality and throughput while lowering operational costs.