The narrow-web flexo printing sector is a dynamic and demanding space, constantly seeking advancements to enhance efficiency, product quality, and sustainability. For decades, conventional UV curing systems have been the workhorse for rapid drying and hardening of inks and coatings. However, the industry is now witnessing a significant paradigm shift towards High-Performance UV LED Curing Solutions. This transition is driven by a confluence of factors, including the need for faster production speeds, superior print quality, reduced energy consumption, and an improved environmental footprint. Understanding the nuances of UV LED technology and its application in narrow-web presses is becoming paramount for any label and packaging printer aiming to maintain a competitive edge.

Understanding the Core Technology: UV LED vs. Traditional UV

At its heart, the difference lies in the light source. Traditional UV curing typically employs mercury vapor lamps. These lamps emit a broad spectrum of UV light, along with significant heat and infrared radiation. While effective, they have inherent drawbacks. They require a warm-up period, have a limited lifespan, and their output degrades over time, necessitating frequent replacement. Furthermore, the heat generated can cause substrate distortion, particularly with sensitive materials like thin films or certain papers, limiting press speed and potentially affecting print registration.

UV LED (Light Emitting Diode) curing, on the other hand, utilizes semiconductor-based diodes that emit UV light at specific wavelengths. This offers several key advantages. UV LEDs are instant on/off, meaning no warm-up time is needed, contributing to immediate operational readiness and reduced energy waste. Their lifespan is significantly longer than mercury lamps, often reaching tens of thousands of hours. Crucially, UV LEDs produce very little heat, emitting predominantly UV light with minimal infrared radiation. This thermal efficiency is a game-changer for narrow-web printing.

Key Advantages of High-Performance UV LED Curing in Narrow-Web Flexo

The adoption of UV LED curing systems in narrow-web flexo presses translates into tangible benefits across various operational aspects.

- Enhanced Curing Speed and Efficiency: UV LEDs can achieve full cure at very high speeds. Their concentrated output at specific wavelengths means inks and coatings are cured more effectively and rapidly. This directly translates to faster production lines, allowing printers to meet demanding turnaround times and increase overall output volume. For narrow-web operations where every second counts, this efficiency gain is substantial.

- Superior Print Quality and Consistency: The precise wavelength output of UV LEDs ensures a consistent curing process. This minimizes the risk of under-curing or over-curing, leading to improved ink adhesion, scratch resistance, and gloss levels. For label and packaging applications where aesthetic appeal and durability are critical, this consistent high quality is invaluable. Furthermore, the reduced heat minimizes ink spread and dot gain, resulting in sharper details and finer graphic reproduction.

- Substrate Versatility and Material Handling: The low heat output of UV LED systems is a significant advantage when printing on heat-sensitive substrates. Thin films, delicate papers, and even some plastics can be printed at high speeds without the risk of warping, shrinking, or deforming. This opens up a broader range of material possibilities for label converters, allowing them to cater to diverse market demands without compromising on quality or speed.

- Energy Savings and Reduced Operating Costs: Compared to traditional mercury lamps, UV LED systems are remarkably energy-efficient. They consume significantly less power to achieve the same curing effect. Their long lifespan also reduces the recurring costs associated with lamp replacement and maintenance. This dual benefit of lower energy bills and reduced consumables directly impacts the bottom line, making UV LED a more economically viable long-term solution.

- Environmental Benefits and Workplace Safety: The energy efficiency of UV LEDs contributes to a lower carbon footprint. Additionally, mercury lamps contain hazardous materials, posing disposal challenges. UV LEDs are mercury-free, making them a more environmentally responsible choice. From a workplace perspective, the reduced heat output can create a cooler and more comfortable working environment. The absence of ozone generation, common with mercury lamps, further enhances air quality within the printing facility.

Implementing UV LED Curing in Your Narrow-Web Flexo Press

Integrating UV LED curing solutions into an existing or new narrow-web flexo press requires careful consideration. The process typically involves selecting the appropriate UV LED curing units that match the press speed, web width, and specific ink/coating chemistries being used.

- Wavelength Selection: UV LEDs are available in different wavelength ranges (e.g., 365nm, 385nm, 395nm, 405nm). The optimal wavelength depends on the photoinitiators present in the ink or coating formulation. Consulting with ink manufacturers is crucial to determine the best-suited wavelength for your specific application to ensure thorough and rapid curing.

- Power Density and Exposure Time: The power density of the UV LED system (measured in W/cm²) and the exposure time the substrate spends under the lamps are critical parameters. These need to be carefully balanced to achieve full cure without damaging the substrate or compromising ink properties. Higher power density allows for shorter exposure times, supporting higher press speeds.

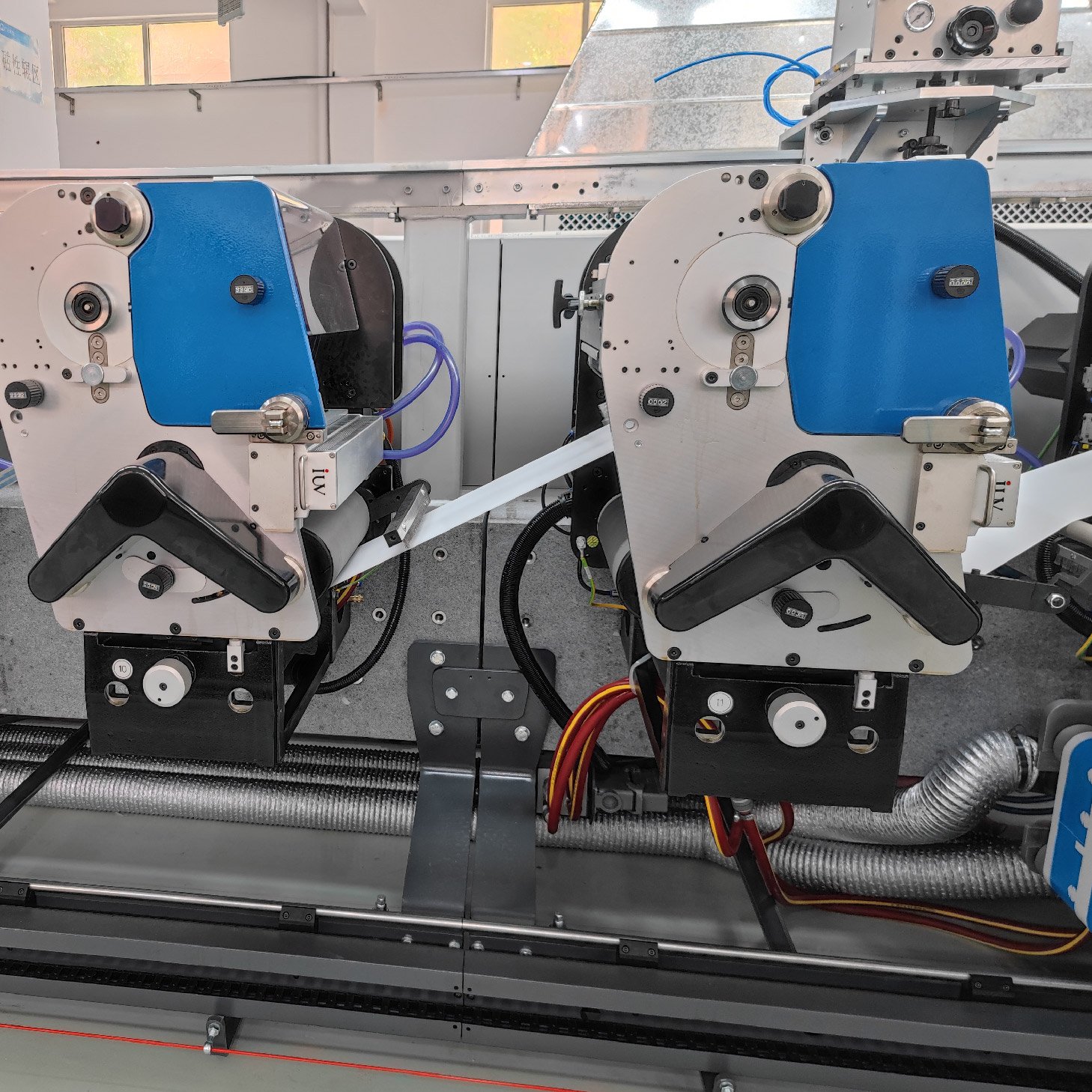

- Integration and Retrofitting: Many narrow-web flexo press manufacturers offer presses with integrated UV LED curing systems as a standard option. For existing presses, retrofitting is also a viable option. This involves installing UV LED curing units into specific print stations or at the end of the press, depending on the workflow and curing requirements. Professional installation and expert advice are recommended to ensure optimal placement and performance.

- Ink and Coating Compatibility: While UV LED technology is advancing rapidly, it’s important to ensure that your current ink and coating suppliers offer formulations optimized for UV LED curing. Many leading ink manufacturers have developed specialized products that leverage the unique benefits of UV LED technology, offering enhanced performance and faster cure speeds.

The Future Landscape: What’s Next for UV LED in Narrow-Web Flexo?

The journey of UV LED curing in the narrow-web flexo industry is far from over. We are seeing continuous innovation in LED technology, leading to higher power outputs, more compact designs, and improved spectral control. The development of new ink and coating formulations tailored for specific UV LED wavelengths will further enhance performance and open up new application possibilities.

As sustainability and efficiency become even more critical drivers in the printing industry, the adoption of UV LED curing solutions is poised for continued growth. Printers who invest in understanding and implementing this technology will undoubtedly be better positioned to meet the evolving demands of the market, deliver superior products, and operate more profitably and responsibly. This is not just an upgrade; it’s a strategic move towards a more advanced and sustainable future for narrow-web flexographic printing.