In the demanding world of narrow-web printing, particularly for labels and packaging, consistent and vibrant color reproduction is paramount. Brands rely on precise color matching to maintain their identity, and any deviation can lead to costly reprints and damaged customer trust. Historically, achieving this level of stability has presented a persistent challenge, with factors like ink chemistry, substrate variations, and the curing process all playing significant roles. However, advancements in LED UV curing technology are revolutionizing how narrow-web printers approach color stability, offering a powerful solution to long-standing issues.

Understanding the Color Challenge in Narrow-Web Printing

Narrow-web printing, encompassing flexographic and offset processes used for labels, flexible packaging, and other specialty applications, operates under tight tolerances. The speed of these presses, combined with the diverse range of inks and substrates employed, creates a dynamic environment where color can shift. Traditional UV curing methods, often relying on mercury vapor lamps, introduced their own set of variables. These lamps emit a broad spectrum of UV light and significant heat. This heat can affect ink viscosity and substrate properties, leading to inconsistencies in ink laydown and, consequently, color. Furthermore, mercury lamps degrade over time, meaning their output changes, requiring frequent monitoring and replacement to maintain consistent curing and color.

The Science Behind LED UV Curing

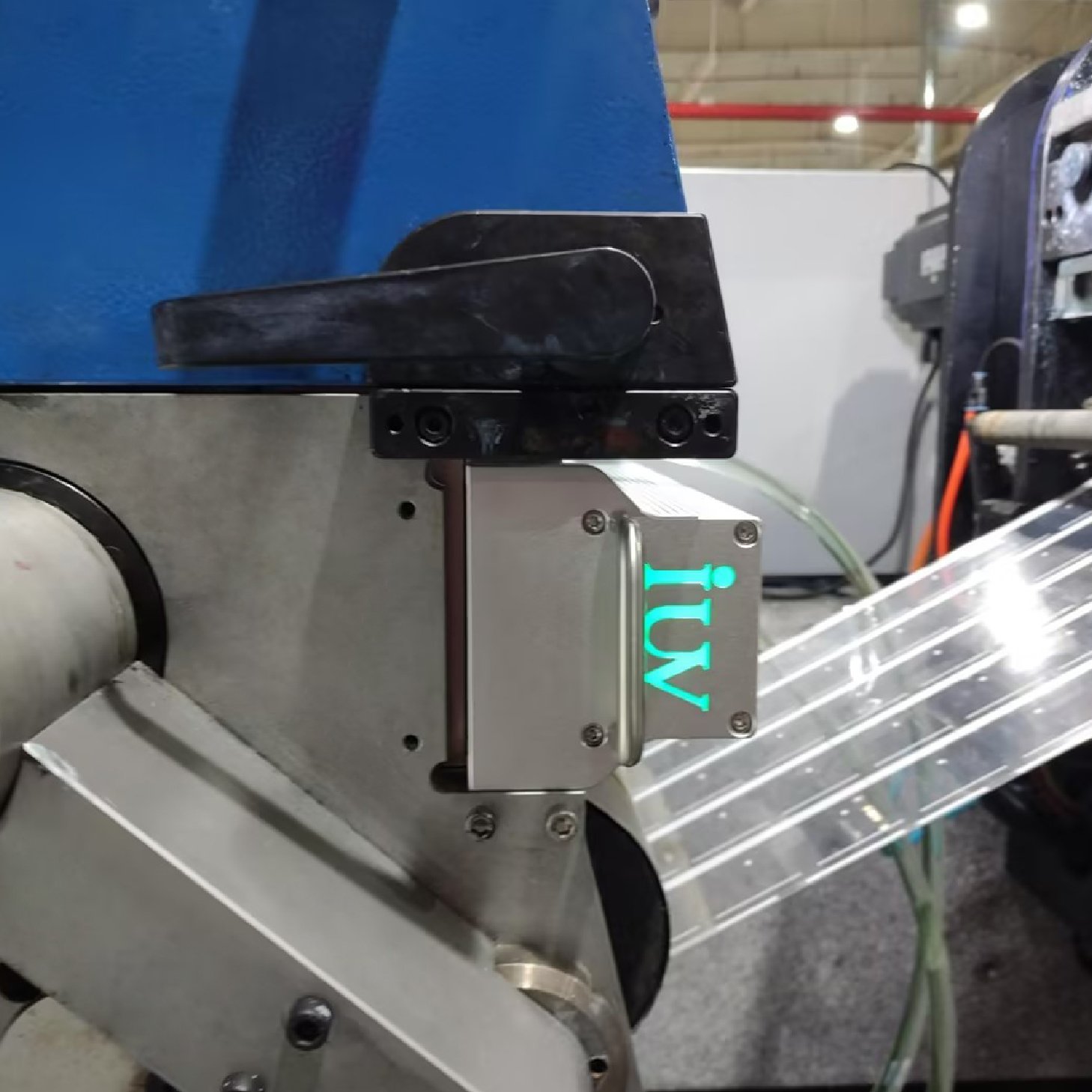

Light Emitting Diode (LED) UV curing represents a paradigm shift. Instead of a broad-spectrum mercury lamp, LEDs emit UV light within a very narrow, specific wavelength band. This targeted emission is a game-changer for color stability. The primary benefits stem from:

- Precise Wavelength Control: Different UV inks are formulated to cure optimally at specific wavelengths. LED systems can be precisely matched to these wavelengths, ensuring efficient and complete polymerization of the ink. This means the ink cures as intended, resulting in a stable, consistent color layer.

- Reduced Heat Generation: Compared to mercury lamps, LEDs produce significantly less heat. This is critical for narrow-web printing on heat-sensitive substrates like films and thin papers. By minimizing heat, LED curing prevents substrate shrinkage or distortion, which can alter ink trapping and color density. It also keeps the ink itself cooler, maintaining its intended viscosity and flow characteristics.

- Consistent Output: LED lamps offer a much longer lifespan and maintain their intensity and wavelength output far more consistently throughout their operational life than mercury lamps. This inherent stability means less variation from batch to batch and job to job, directly contributing to repeatable color results.

Impact on Flexographic and Offset Narrow-Web Presses

Both flexographic and offset printing processes on narrow-web presses can benefit immensely from advanced LED curing.

In Flexography: Flexo printing often involves thicker ink layers and a wider range of anilox roll and plate combinations. Heat from traditional UV lamps can cause these inks to skin over or cure unevenly, leading to poor adhesion and color shifts. The controlled, low-heat output of LEDs ensures that the ink cures thoroughly from top to bottom, maintaining the intended dot gain and color saturation. This is particularly valuable for fine details and process color printing where subtle variations can be easily noticed.

In Offset Lithography: While offset typically uses thinner ink films, color consistency remains a critical factor. The reduced heat from LED curing prevents premature drying or changes in ink tack, ensuring a cleaner transfer from the blanket to the substrate. This translates to sharper dots, more consistent solids, and a more reliable color gamut, especially when dealing with metallic inks or special effect varnishes that are sensitive to temperature fluctuations.

Enhancing Color Stability: Practical Applications of LED UV

Integrating advanced LED UV curing into narrow-web operations directly addresses several key areas impacting color stability:

- Ink Chemistry Optimization: Modern UV ink formulations are increasingly designed to work synergistically with LED curing. Printers can select inks specifically engineered for LED wavelengths, ensuring maximum cure efficiency and, therefore, the most stable color appearance. This often means achieving a wider color gamut and better color gamut repeatability.

- Substrate Versatility: The low-heat profile of LED curing opens up printing possibilities on a broader range of substrates that might have been previously unsuitable for UV curing due to heat sensitivity. This includes a variety of plastic films, thin papers, and even some sensitive packaging materials, all while maintaining color integrity.

- Process Control and Repeatability: The consistent output of LED systems simplifies process control. Once parameters are set for a specific job, printers can rely on them to remain stable over the production run. This reduces the need for constant color adjustments, saving time and reducing waste. For brand owners, this means consistent product appearance across different production batches.

- Intercolor and Overprint Varnish Applications: In multi-color printing, ensuring each layer cures properly before the next is applied is crucial. LED curing provides a fast, efficient cure between stations, preventing ink smearing and ensuring true colors build up accurately. Similarly, LED-cured overprint varnishes maintain their clarity and gloss without yellowing or affecting the underlying ink colors due to excessive heat.

The Future is Cool and Consistent

The adoption of advanced LED UV curing in narrow-web printing is not just a trend; it’s a significant technological leap forward. The ability to precisely control the curing process with targeted wavelengths and minimal heat offers unparalleled consistency in color reproduction. For printers striving for efficiency, quality, and brand satisfaction, investing in LED technology is becoming an essential strategy. It directly combats the variables that have historically plagued color stability, paving the way for sharper, more vibrant, and reliably consistent narrow-web printed products. As the technology continues to evolve, expect even greater advancements that further solidify LED UV curing as the cornerstone of modern narrow-web printing for achieving perfect color, every time.