The convergence of flexographic and digital printing technologies in the narrow-web sector has opened up exciting new possibilities for label production. This evolution has been further accelerated by the integration of LED UV curing systems, offering distinct advantages in terms of speed, efficiency, and environmental impact. Understanding this synergy is key for label converters aiming to optimize their operations and expand their service offerings.

Flexography, a long-standing staple in narrow-web printing, excels at high-volume production with its robust and cost-effective method. It relies on raised flexible plates to transfer ink onto a substrate. When combined with digital printing capabilities, often in a hybrid platform, it allows for the best of both worlds: the speed and economy of flexo for process colors and extended runs, alongside the variable data and short-run flexibility of digital.

Digital printing in this context typically refers to inkjet or toner-based technologies, offering on-demand printing and the ability to handle intricate designs or personalized labels without the need for traditional plate-making. The hybrid approach, therefore, leverages the strengths of each, creating a versatile and powerful production solution.

The role of UV curing in this setup cannot be overstated. Traditionally, UV curing used mercury vapor lamps, which generated significant heat, consumed a lot of energy, and contained hazardous materials. The advent of LED UV curing has revolutionized this aspect of the printing process.

The Advantages of LED UV Curing

LED UV curing utilizes light-emitting diodes to emit ultraviolet light at specific wavelengths. This technology brings a cascade of benefits to the narrow-web hybrid printing environment:

- Energy Efficiency: LEDs consume considerably less power compared to mercury lamps, leading to substantial cost savings on electricity bills. This efficiency is particularly impactful in high-speed, continuous printing processes common in narrow-web applications.

- Reduced Heat Transfer: LEDs emit a narrow spectrum of UV light with minimal heat generation. This is crucial for printing on heat-sensitive substrates like thin films or certain papers, preventing material distortion or damage. Lower heat also contributes to a cooler working environment.

- Instant On/Off: Unlike mercury lamps that require a warm-up period, LEDs can be switched on and off instantaneously. This capability is ideal for digital printing workflows where print heads may stop and start frequently, preventing ink buildup and ensuring precise curing at the right moment.

- Longer Lifespan: LED systems boast a significantly longer operational life than traditional UV lamps, reducing downtime for replacements and associated maintenance costs.

- Environmental Friendliness: The absence of mercury and reduced energy consumption make LED UV curing a more environmentally sustainable option, aligning with the growing demand for eco-friendly printing solutions.

- Precise Wavelength Control: LEDs emit UV light at specific wavelengths, which can be precisely matched to the absorption spectra of UV-curable inks and coatings. This ensures optimal and consistent curing, leading to improved ink adhesion, scratch resistance, and overall print quality.

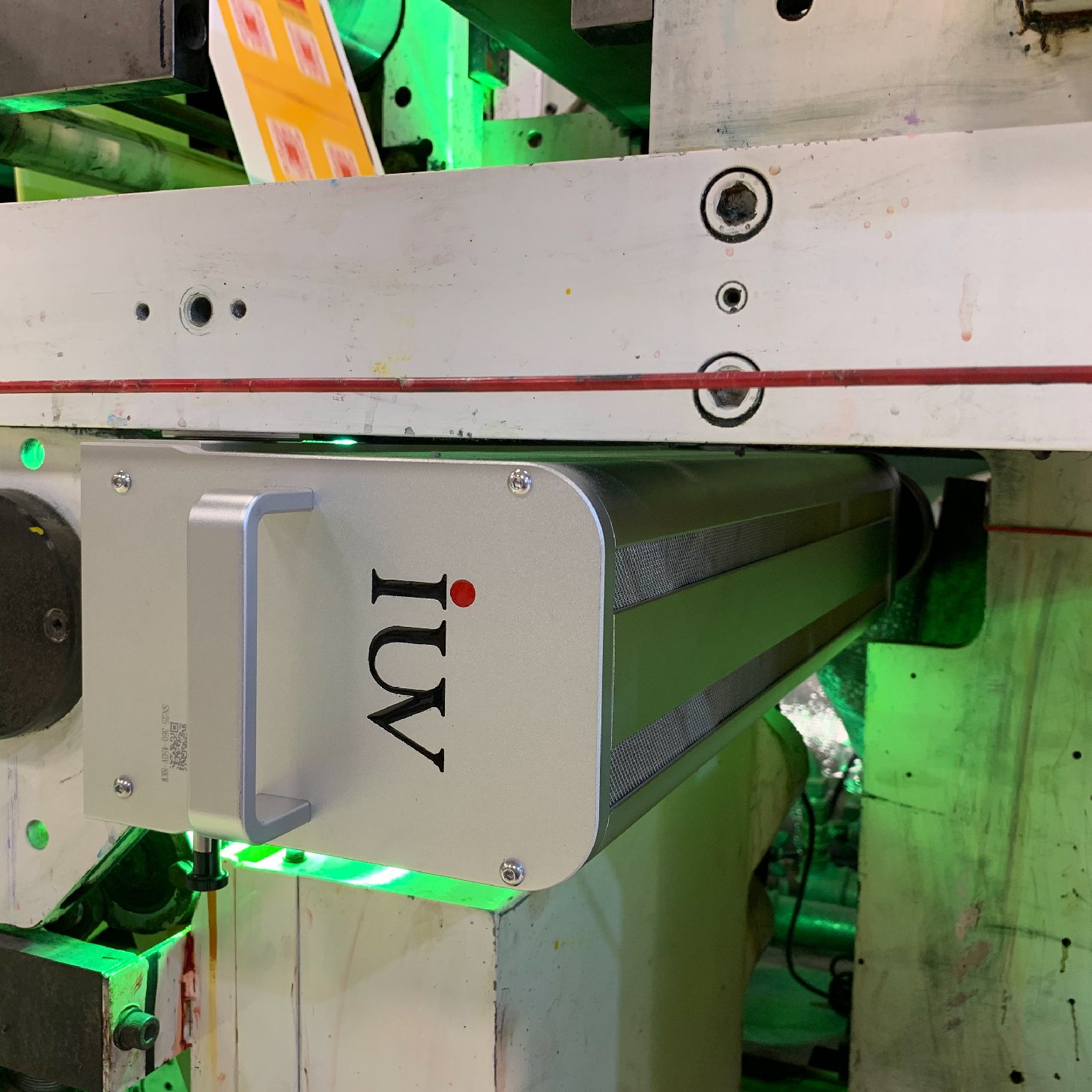

- Compact Design: LED UV curing units are often more compact, allowing for easier integration into existing or new narrow-web hybrid presses without requiring extensive modifications to the press layout.

Impact on Narrow-Web Hybrid Platforms

The integration of LED UV curing profoundly impacts the capabilities of narrow-web hybrid flexo-digital platforms.

In a hybrid setup, a flexographic unit might be used for applying specialty effects, varnishes, or base colors, while digital units handle variable data or complex graphics. LED UV curing stations can be strategically placed between these units or at the end of the press to cure inks and coatings instantly.

For instance, a label converter might use a flexo unit with a special effect ink, followed by an LED UV dryer. Then, a digital inkjet unit can print a variable image or text, which is then cured by another LED UV unit. This sequence allows for high-quality, durable labels with unique finishes and personalized information, all produced efficiently on a single press.

The rapid curing provided by LEDs ensures that inks and coatings are fully cross-linked before the substrate moves to the next printing station or is wound onto a roll. This prevents smudging, blocking (where printed surfaces stick together), and contamination, which are critical considerations in high-speed label production.

Specific Applications and Benefits

The combined power of hybrid printing and LED UV curing is particularly beneficial for specific label applications:

- Cosmetic and Pharmaceutical Labels: High-quality aesthetics and information clarity are paramount. Hybrid presses with LED UV curing can deliver premium finishes and the precision needed for critical product information and regulatory text.

- Industrial and Chemical Labels: Durability against harsh environments, chemicals, and abrasion is essential. The strong, cross-linked coatings achieved with LED UV curing provide the necessary resilience.

- Promotional and Variable Data Labels: The ability to print unique serial numbers, barcodes, or promotional messages on each label, combined with high-quality graphics and durable finishes, is a direct outcome of this technological integration.

Considerations for Implementation

While the benefits are clear, implementing LED UV curing in a narrow-web hybrid platform requires careful consideration:

- Ink and Coating Formulation: UV-curable inks and coatings must be specifically formulated for LED UV curing. Their photoinitiators need to be sensitive to the specific wavelengths emitted by the LEDs. Working with ink suppliers to ensure compatibility is vital.

- Substrate Selection: While LEDs are gentler on substrates, understanding the thermal properties and surface characteristics of the chosen material remains important for optimal ink adhesion and print quality.

- Press Integration: The physical integration of LED UV curing units onto the press needs to be planned to ensure proper ventilation, power supply, and alignment with the printing process. The compact nature of LEDs simplifies this compared to older technologies.

- Maintenance and Operation: While LEDs have a long lifespan, understanding their operational parameters, such as power output and spectrum, is important for consistent performance. Training operators on the nuances of LED UV curing is also beneficial.

The Future Landscape

The trend towards integration and efficiency in narrow-web printing will undoubtedly continue. Hybrid flexo-digital platforms equipped with LED UV curing represent a significant step forward, offering label converters the flexibility to meet diverse market demands with speed, quality, and sustainability. As LED technology continues to advance, we can expect even greater efficiencies and new applications to emerge, further solidifying its position as a critical component in modern label production. This convergence is not just an incremental improvement; it is a fundamental shift in how high-quality, customized labels are produced.