The printing industry is constantly evolving, driven by demands for efficiency, quality, and, increasingly, sustainability. For businesses in the narrow-web sector, particularly those involved in label printing, this evolution presents both challenges and opportunities. One of the most significant environmental concerns in printing has been the emission of Volatile Organic Compounds (VOCs). Traditional printing methods, especially those using solvent-based inks, contribute to air pollution and can pose health risks. However, advancements in technology are providing viable solutions. Narrow-web LED UV flexographic (flexo) printing systems have emerged as a powerful tool for significantly reducing VOC emissions, offering a more sustainable path forward.

Understanding VOC Emissions in Printing

Volatile Organic Compounds are carbon-containing chemicals that readily evaporate into the air. In printing, VOCs are primarily found in inks, coatings, and cleaning solutions. Solvent-based inks, a mainstay in many printing applications for decades, rely on solvents to carry pigments and allow the ink to transfer to the substrate. Once printed, these solvents evaporate, releasing VOCs into the atmosphere. This process not only impacts air quality but also necessitates robust ventilation systems and emission control technologies, adding to operational costs and complexity.

The environmental impact of VOCs is well-documented. They can contribute to the formation of ground-level ozone, a major component of smog, which has detrimental effects on human respiratory health and can damage vegetation and ecosystems. Regulations regarding VOC emissions are becoming increasingly stringent worldwide, pushing the printing industry to seek cleaner alternatives.

The Rise of UV Curing Technology

Ultraviolet (UV) curing technology has been a game-changer in the printing world. Instead of relying on solvent evaporation, UV-curable inks contain monomers and oligomers that are solidified (cured) almost instantly when exposed to UV light. This chemical process, known as photopolymerization, transforms the liquid ink into a solid, durable film without releasing significant amounts of VOCs.

Historically, UV curing systems used mercury vapor lamps. While effective, these lamps have drawbacks. They consume considerable energy, generate substantial heat, and have a limited lifespan, requiring frequent replacement and specialized disposal due to mercury content. This is where LED UV curing has made a monumental impact.

Narrow-Web LED Flexo: A Sustainable Printing Solution

Narrow-web printing typically refers to printing on substrates less than 20 inches wide, commonly used for labels, packaging, and other specialized applications. Flexography is a highly versatile printing technique that uses flexible relief plates. Combining narrow-web flexo with LED UV curing technology offers a compelling synergy for sustainable printing.

How Narrow-Web LED Flexo Works:

- Substrate Feeding: The narrow web (e.g., paper, film, or foil) is fed from a roll through the printing press.

- Ink Application: In each print station, an anilox roll transfers ink from the ink fountain to a raised image carrier (the flexo plate). The plate then transfers the ink onto the substrate.

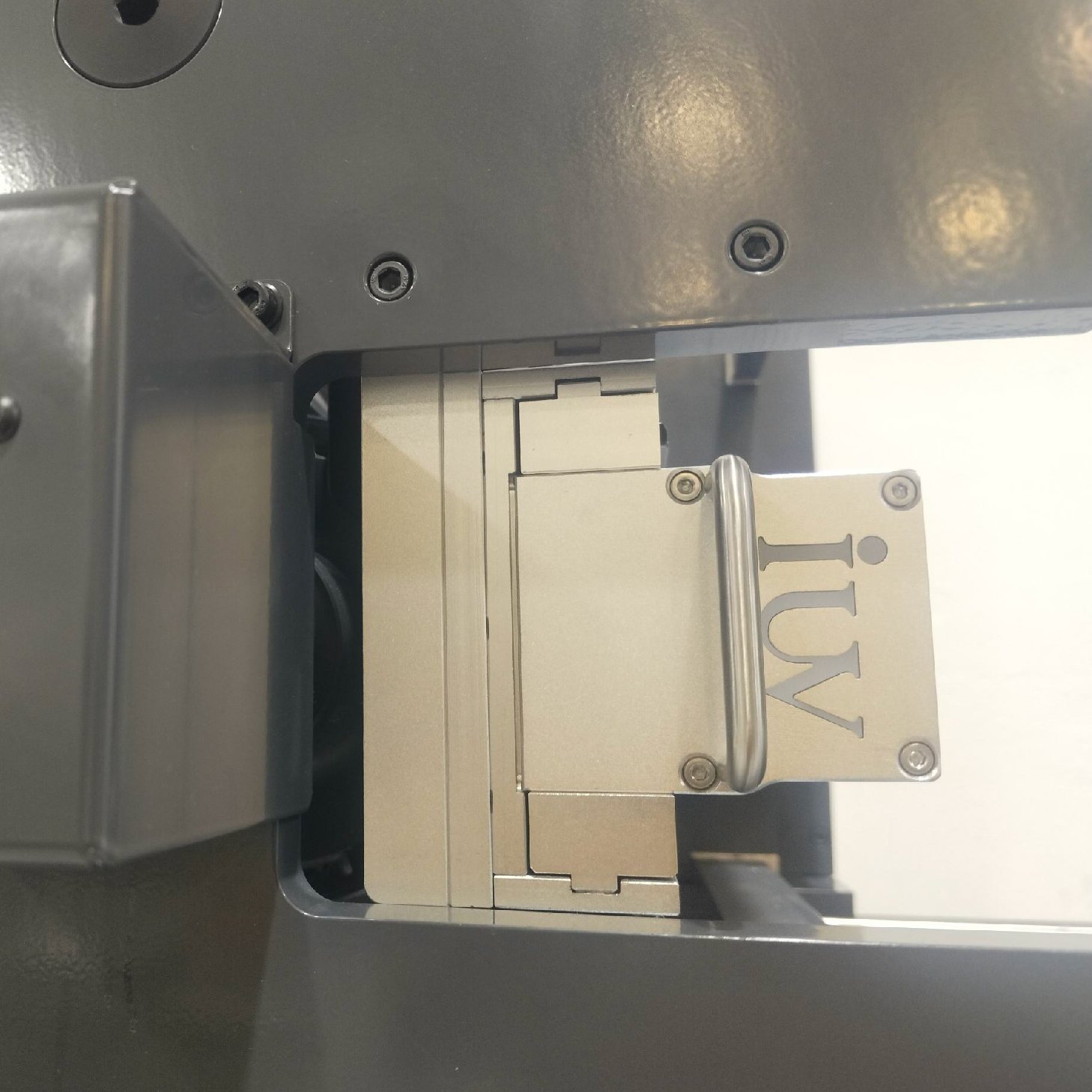

- LED UV Curing: Immediately after ink application in each station, or at the end of the printing process, powerful LED UV lamps emit specific wavelengths of UV light. This light initiates the photopolymerization of the UV-curable ink, instantly solidifying it.

- Repeatability and Efficiency: This process is repeated for each color in the design. Because the ink cures so quickly, multiple colors can be printed in close succession without smudging or requiring extensive drying times between stations, as would be the case with conventional inks.

Key Advantages of Narrow-Web LED UV Flexo for VOC Reduction

The adoption of narrow-web LED UV flexo systems directly addresses the issue of VOC emissions through several mechanisms:

- VOC-Free Inks: The primary advantage is the inherent nature of UV-curable inks. These inks are formulated without the volatile solvents found in traditional inks. As a result, the evaporation of VOCs during the printing process is virtually eliminated. This means cleaner air inside the print shop and a reduced environmental footprint.

- Reduced Energy Consumption: Compared to traditional mercury UV lamps, LED UV curing systems are remarkably energy-efficient. They consume significantly less power to achieve the same level of curing. Furthermore, LEDs can be turned on and off instantly, meaning energy is only used when printing is actually occurring, unlike mercury lamps which require warm-up and cool-down periods. This energy efficiency contributes to a lower overall carbon footprint for the printing operation.

- Lower Heat Generation: LED UV lamps emit less infrared radiation (heat) than mercury lamps. This is a significant benefit when printing on heat-sensitive substrates, such as certain plastics or thin films commonly used in label and flexible packaging. Reduced heat transfer means less energy is wasted on unwanted heating, and the risk of substrate distortion or damage is minimized. This also translates to potentially less need for elaborate cooling systems.

- Faster Curing Speeds: The rapid curing capabilities of LED UV systems allow for higher printing speeds. This increased throughput means more jobs can be completed in less time, enhancing productivity without compromising on print quality or environmental standards.

- No Solvent Odors: The absence of evaporating solvents also means a reduction in the characteristic, often unpleasant, odors associated with traditional printing. This creates a more pleasant working environment for press operators and can be a significant benefit for the end-user of printed materials, especially in food packaging applications.

- Elimination of Solvent-Based Cleaning: Many printing operations also use solvent-based cleaners for their presses and plates. With UV-curable inks, cleaning can often be done with water-based or less aggressive cleaning solutions, further reducing VOC emissions and potential health hazards.

Addressing Common Concerns and Considerations

While the benefits are clear, transitioning to any new technology requires careful consideration.

- Ink Formulation and Substrate Compatibility: Not all UV inks are created equal, and compatibility with various substrates (paper, various plastic films, foils) is crucial. Ink manufacturers have developed a wide range of UV-curable inks specifically for flexographic printing on narrow webs, ensuring excellent adhesion and performance. It is important to work with reputable ink suppliers to select the correct formulations for your specific applications.

- LED Lamp Wavelengths and Power: LED UV systems operate at specific wavelengths (e.g., 365 nm, 385 nm, 395 nm, 405 nm). The choice of wavelength and the power output of the LEDs must be matched to the photoinitiators in the UV ink to ensure complete and efficient curing. Modern LED systems offer adjustable power and wavelength options, providing flexibility.

- Capital Investment: The initial investment in an LED UV flexo system can be higher than traditional solvent-based equipment. However, this must be weighed against the long-term savings in energy, reduced waste, lower regulatory compliance costs, and the enhanced marketability of sustainable printing solutions.

- Operational Expertise: While the technology is advanced, it is generally user-friendly. Press operators may require some training on handling UV inks and operating the LED curing units, but the core flexographic printing principles remain the same.

The Future of Sustainable Label Printing

The label printing industry is at the forefront of adopting sustainable practices. With growing consumer and regulatory pressure for eco-friendly products, businesses that can demonstrate a commitment to reducing their environmental impact gain a competitive advantage. Narrow-web LED UV flexo systems provide a tangible way to achieve this.

By minimizing or eliminating VOC emissions, reducing energy consumption, and offering high-quality, durable prints, these systems position printing companies as responsible stewards of the environment. They contribute to cleaner manufacturing processes, healthier workplaces, and ultimately, a more sustainable product lifecycle. As the technology continues to mature and become more accessible, it is poised to become the standard for environmentally conscious narrow-web printing operations worldwide. The shift is not just about compliance; it’s about innovation, efficiency, and building a more sustainable future for the printing industry.