The pursuit of vibrant, impactful color is a constant in the world of printing. For label and narrow web converters, achieving superior color density directly influences brand perception and product appeal. This is particularly true in flexographic printing, where plate technology plays a pivotal role. Traditional methods sometimes struggle to deliver the deepest blacks and richest hues. However, advancements in LED-optimized flexo plate technologies are now offering a significant leap forward, allowing printers to push the boundaries of color saturation.

Understanding Color Density in Flexography

Color density, in printing terms, refers to the amount of ink that is transferred to the substrate. Higher density means a richer, more opaque color. In flexography, ink transfer is governed by several factors: the anilox roll cell volume and count, the ink viscosity and transfer rate, the impression cylinder pressure, and crucially, the characteristics of the printing plate. A plate’s ability to hold ink and release it cleanly onto the substrate is paramount. If a plate cannot adequately carry sufficient ink, the resulting printed color will appear dull or washed out, regardless of how good the ink or anilox roll is.

The Flexo Plate’s Critical Role

Flexographic plates are essentially raised image carriers. They are typically made from photopolymer materials. When exposed to UV light through a negative film or directly from a digital file (CTP – Computer-to-Plate), specific areas of the photopolymer cure, becoming hardened and forming the printable image. Unexposed areas are then washed away, leaving the raised image. The physical properties of this cured photopolymer, such as its durometer (hardness), surface characteristics, and ink-receptive qualities, directly impact ink transfer. Older plate formulations or non-optimized plates might have a surface that doesn’t accept ink optimally or releases it inconsistently.

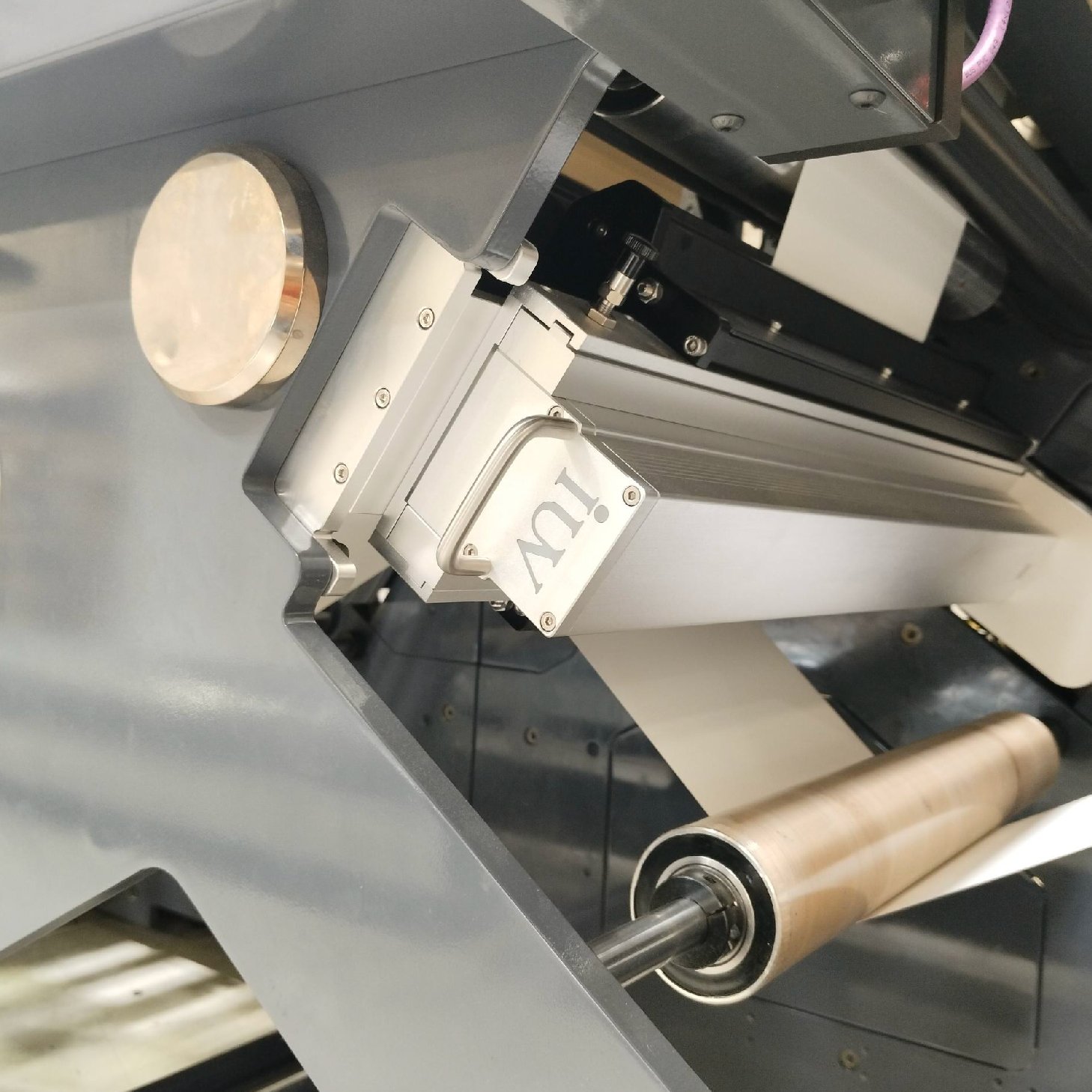

Introducing LED UV Curing and Its Advantages

The printing industry has seen a major shift towards UV curing technology for drying inks. UV curing uses ultraviolet light to instantly polymerize ink, making it dry and adhere to the substrate. This offers significant advantages over traditional heat-set or solvent-based drying, including faster print speeds, reduced energy consumption, and a wider range of printable substrates. Within UV curing, a significant innovation has been the advent of LED UV curing. Unlike traditional mercury vapor lamps, LED UV lamps emit UV light within a very specific wavelength range, typically centered around 395nm. This focused emission offers several benefits.

Optimizing Plates for LED UV Curing

This is where LED-optimized flexo plate technologies come into play. These plates are specifically engineered to work in synergy with the narrow wavelength output of LED UV lamps. The photopolymer formulations are designed to cure highly efficiently and effectively under this specific light spectrum. This optimized curing process leads to several key improvements directly impacting color density.

Enhanced Ink Transfer and Ink Holding

LED-optimized plates often feature a surface structure and material composition that promote superior ink uptake. The cured ink dots are sharper and more defined. This is because the LED curing process can achieve a more complete and consistent cure, leading to a more robust dot structure on the plate. A well-defined and resilient ink dot can hold more ink. When this plate then transfers ink to the substrate, it does so with greater fidelity and completeness. This means more ink pigment reaches the paper or film, resulting in a visually denser and more saturated color.

Sharper Dot Reproduction and Fine Detail

Beyond just density, the ability to reproduce fine detail is crucial for high-quality labels. LED-optimized plates, coupled with advanced platemaking techniques like high-definition anilox rolls and precise screening, can achieve exceptionally sharp dot edges. The efficient and focused curing from LED lamps minimizes light scatter during the platemaking process. This leads to crisper dot formation on the plate, which in turn translates to sharper printed dots on the substrate. Sharper dots mean less ink spread and a cleaner appearance, which indirectly contributes to perceived color density by reducing “muddy” or blurred effects.

Reduced Ink Mottle and Improved Ink Laydown

Ink mottle, or uneven ink distribution, can significantly degrade color appearance and reduce perceived density. LED-optimized plates, by promoting better ink transfer and more consistent dot formation, help to mitigate mottle. The plate surface is designed to accept and release ink uniformly. This leads to a smoother, more consistent ink laydown across the printed area. When ink lays down smoothly and evenly, the color appears richer and more solid, enhancing its overall density. This is especially important for solid color areas and deep blacks.

The Synergy with Narrow Web and Label Printing

For the narrow web and label printing sector, these enhancements are particularly impactful. Labels often require high visual impact to stand out on crowded shelves. Deep, saturated colors draw the consumer’s eye. By employing LED-optimized flexo plates, narrow web printers can achieve premium print quality that rivals or surpasses other printing methods. The ability to print vibrant colors with exceptional sharpness and consistency is a competitive advantage. This technology allows for the effective reproduction of brand colors, ensuring brand integrity across different print runs and different label applications.

Considerations for Implementation

To fully leverage the benefits of LED-optimized flexo plate technologies for enhanced color density, several factors should be considered.

- Plate Material Selection: Choose plates specifically designated as “LED-optimized” or “LED-curable.” These materials are engineered for the specific light spectrum of LED UV lamps.

- Platemaking Process: Ensure your platemaking equipment and process are compatible with these advanced plates. This includes the exposure and washout parameters.

- Anilox Roll Pairing: While the plate is key, optimal anilox roll selection remains vital for ink transfer. Work with your anilox supplier to find the best combination of cell volume and line screen for your ink and desired density.

- Ink Formulation: While LED-optimized plates work with various inks, certain ink formulations might be designed to perform even better with this technology. Consult with your ink supplier.

- Press Setup: Proper impression settings and anilox roll gearing are always important for consistent ink transfer and dot reproduction.

The Future of Color Density in Flexo

The evolution of flexographic printing plates, particularly those designed for LED UV curing, represents a significant step towards achieving higher levels of color density and overall print quality. These technologies empower converters to produce labels and packaging that are not only visually striking but also consistently excellent. By understanding and implementing these advanced plate solutions, printers can unlock new levels of color vibrancy, achieve sharper detail, and ultimately, create more compelling printed products that resonate with consumers. The investment in LED-optimized flexo plates is an investment in superior color, a critical component for brand success in today’s competitive market.