In the demanding world of narrow web printing, particularly for applications like labels and flexible packaging, maintaining consistent print quality is paramount. A significant challenge arises when working with heat-sensitive substrates, such as certain plastics and delicate papers, which can warp, deform, or even degrade under the high temperatures typically associated with traditional drying methods. This is where the integration of automated UV curing systems, specifically those employing LED UV technology, offers a transformative solution, dramatically improving print stability and overall output quality.

The inherent nature of heat-sensitive materials means that conventional hot air or IR drying can introduce unwelcome variability. The heat applied can cause shrinkage or expansion, leading to misregistration issues, particularly problematic in multi-color printing processes like flexography and offset lithography. Furthermore, excessive heat can compromise the integrity of the substrate itself, resulting in weaker bonds, cracking, or an undesirable surface finish. Automated UV curing systems, by contrast, operate at significantly lower temperatures, effectively mitigating these risks.

The Science of UV Curing and Heat Sensitivity

UV curing is a photochemical process where ultraviolet light initiates a rapid polymerization reaction in specially formulated inks, coatings, and adhesives. This process transforms the liquid into a solid, durable film almost instantaneously. The key advantage for heat-sensitive substrates lies in the nature of the energy transfer. Unlike thermal drying, which relies on convective and radiant heat to evaporate solvents, UV curing uses photons to drive a chemical change. This means the energy is delivered directly to the photoinitiators within the ink, causing a rapid cure with minimal heat introduced to the substrate itself.

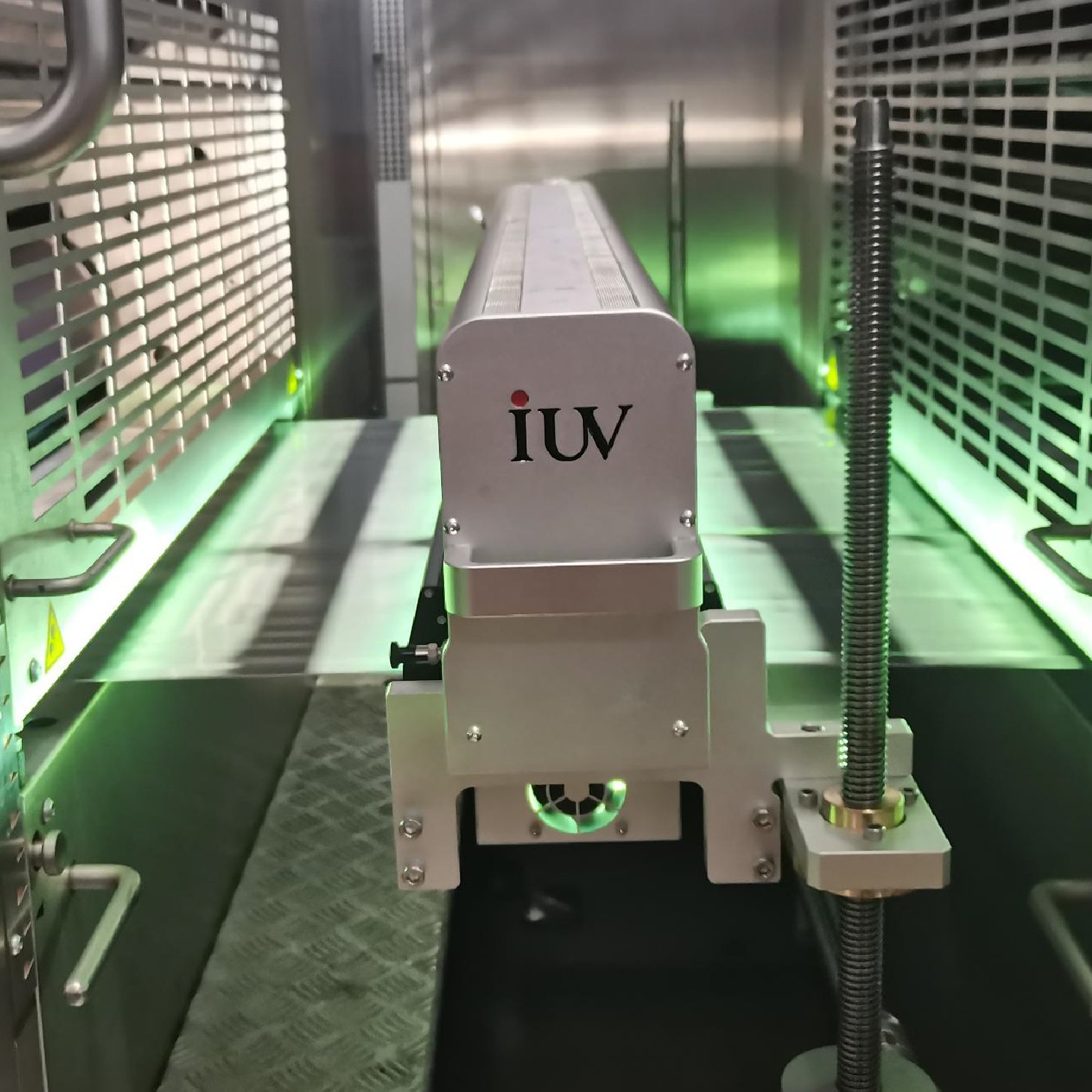

LED UV curing, a more recent advancement, takes this benefit a step further. Light Emitting Diodes emit UV light at specific wavelengths, which can be precisely controlled. This targeted emission is more energy-efficient than traditional mercury vapor lamps and generates far less waste heat. The result is an even cooler curing process, making LED UV ideal for the most demanding heat-sensitive applications.

Advantages in Narrow Web and Flexographic Printing

For narrow web printers, efficiency and precision are not just desirable; they are essential. Whether producing intricate labels for pharmaceuticals, food packaging, or consumer goods, every centimeter of substrate matters. In flexographic printing, where ink is transferred from a raised image carrier to the substrate, accurate ink transfer and drying are critical for achieving sharp dot reproduction and vibrant colors.

When UV-curable inks are used in flexography on heat-sensitive substrates, traditional drying can lead to the ink flowing or spreading before it’s fully cured, blurring fine details. Automated UV systems, particularly those with precise control over lamp intensity and exposure time, ensure that the ink cures rapidly and completely upon exposure. This immediate solidification prevents ink movement, preserving the integrity of the printed image and ensuring consistent color density across the entire print run.

The automation aspect is crucial here. Modern UV curing units are integrated directly into the printing press. As the substrate moves through the press, it passes under the UV lamps immediately after ink application. This automated workflow eliminates manual intervention, reducing the potential for errors and ensuring that each section of the substrate receives the optimal UV dose. This consistency is vital for maintaining brand integrity and meeting stringent regulatory requirements, especially in food and pharmaceutical labeling where traceability and quality are non-negotiable.

Benefits for Offset Lithography on Sensitive Stocks

Offset lithography, while known for its ability to produce high-quality photographic images, also faces challenges with heat-sensitive substrates. The process often involves the transfer of ink to a blanket and then to the substrate. If the substrate is susceptible to heat, the pressure and any residual warmth from the printing process, combined with traditional drying, can lead to dimensional instability.

Automated UV curing, applied immediately after the ink transfer in offset presses, effectively locks the ink in place. This rapid cure prevents ink set-off (transferring ink to the back of the next sheet) and allows for immediate stacking or further processing without concerns about smudging or substrate deformation. For printers working with thin films or coated papers that are prone to curling or wrinkling under heat, UV curing offers a cooler, faster, and more stable drying solution. The ability to cure thick ink layers or multiple ink colors in a single pass without excessive heat build-up is a significant advantage, contributing to faster production speeds and reduced waste.

Optimizing Ink and Substrate Interaction

The success of UV curing on heat-sensitive substrates also hinges on the careful selection of UV-curable inks and coatings. Formulators have developed a range of inks specifically designed for low-temperature curing and excellent adhesion to a wide variety of substrates. These inks often contain specialized photoinitiators that are highly responsive to the specific wavelengths emitted by LED UV lamps.

Furthermore, advancements in substrate coatings and surface treatments can enhance their receptiveness to UV curing while maintaining their thermal sensitivity. The interaction between the ink chemistry, the substrate, and the UV light source is a complex but optimizable equation. Automated UV systems provide the control necessary to fine-tune this interaction, ensuring optimal cure speeds, adhesion, and finish, even on the most challenging materials.

The Role of Automation in Precision Control

Automation in UV curing systems goes beyond simply placing lamps over the substrate. Modern systems offer sophisticated controls for:

- Intensity Adjustment: The power output of the UV lamps can be precisely adjusted to match the ink system and the substrate’s thermal threshold. This prevents over-curing or under-curing.

- Wavelength Selection: Particularly with LED UV, the ability to select specific wavelengths ensures maximum absorption by the photoinitiators, leading to efficient curing with minimal heat generation.

- Exposure Time: The speed of the press dictates the exposure time. Automated systems synchronize the UV lamps with the press speed, ensuring consistent energy delivery.

- Cooling Mechanisms: While UV curing is inherently cooler, advanced systems often incorporate integrated cooling systems to further manage any minimal heat generated, especially critical for ultra-sensitive materials.

- Monitoring and Diagnostics: Many automated systems include sensors that monitor UV output and can alert operators to any deviations, ensuring ongoing print stability and quality control.

This level of precise control is what truly differentiates automated UV systems. It allows printers to move beyond guesswork and rely on repeatable, data-driven processes to achieve consistent results, regardless of the substrate’s thermal sensitivity.

Conclusion: A Future-Proof Solution

The growing demand for high-quality, efficient printing on a diverse range of substrates, including those that are heat-sensitive, makes automated UV curing systems an indispensable technology. By leveraging the power of UV light and the precision of automation, printers in the narrow web, flexographic, and offset sectors can overcome the limitations of traditional drying methods. This leads to enhanced print stability, superior image quality, reduced waste, and faster production cycles. As printing technologies continue to evolve, the role of advanced UV curing solutions will only become more critical in meeting the complex challenges of modern print production.