The quest for flawless label production is an ongoing challenge in the printing industry. Human error, an inherent aspect of any manual process, can lead to costly mistakes, wasted materials, and damaged brand reputation. Fortunately, advancements in technology, particularly automated UV systems, are offering a powerful solution to significantly reduce these errors in label manufacturing.

The Human Element in Label Printing

Label printing, whether flexographic, offset, or narrow web, involves a complex series of steps. From plate mounting and ink viscosity adjustments to registration control and quality checks, each stage requires meticulous attention to detail. Even the most experienced press operators can make mistakes, especially under pressure or during long shifts. Misregistered colors, ink smudges, improper curing, and incorrect placement are just a few examples of how human error can manifest. These errors not only impact the immediate production run but can also lead to customer dissatisfaction and lost business.

The Promise of UV Curing Technology

Ultraviolet (UV) curing has revolutionized printing by enabling rapid drying and hardening of inks and coatings. Unlike traditional heat-set or air-dry methods, UV curing uses UV light to initiate a photochemical reaction, instantly solidifying the ink. This process offers several advantages:

- Speed: UV inks cure almost instantaneously, allowing for faster printing speeds and reduced turnaround times.

- Durability: Cured UV inks are highly resistant to abrasion, chemicals, and fading, resulting in more robust labels.

- Versatility: UV inks can be applied to a wide range of substrates, including plastics, foils, and coated papers, which are common in label production.

- Environmental Benefits: UV curing systems typically do not emit volatile organic compounds (VOCs), making them a more environmentally friendly option.

The Rise of Automated UV Systems

While UV curing itself is a significant technological leap, the integration of automation into UV curing systems elevates its potential to combat human error. Automated UV systems are designed to precisely control every aspect of the UV curing process, minimizing the need for manual intervention and its associated risks.

Precise Control Over Exposure

One of the primary ways automated UV systems reduce errors is through their ability to precisely control UV exposure. Factors such as UV lamp intensity, conveyor belt speed, and exposure time are critical for proper ink curing.

- Intensity and Dose: Automated systems can maintain consistent UV lamp intensity throughout the production run. Fluctuations in intensity, often caused by manual adjustments or aging lamps, can lead to under-curing or over-curing. Under-cured ink is prone to smudging and poor adhesion, while over-cured ink can become brittle and discolored. Automated systems ensure the correct UV dose is delivered to every part of the label.

- Speed and Synchronization: The speed of the conveyor belt must be perfectly synchronized with the UV lamp output. Automated systems manage this synchronization, ensuring that each label receives the optimal amount of UV exposure as it passes under the lamps. Manual operators might inadvertently alter the belt speed, disrupting this crucial balance.

Consistent Ink Adhesion and Durability

Proper UV curing is paramount for achieving excellent ink adhesion and the desired durability of the label. When inks are not fully cured, they can easily be scratched, smudged, or react negatively with the product they are labeling, especially in demanding applications. Automated UV systems ensure that the photochemical reaction proceeds to completion, leading to:

- Superior Adhesion: Properly cured inks bond strongly to the substrate, preventing peeling or lifting, which is vital for labels subjected to handling, moisture, or temperature changes.

- Enhanced Scratch and Chemical Resistance: The cross-linking that occurs during UV curing creates a robust ink layer that can withstand significant wear and tear, as well as exposure to various chemicals. This is particularly important for product labels in industries like automotive, industrial, or cleaning supplies.

Minimizing Curing-Related Defects

Human error can also contribute to defects related to the curing process itself. For instance, inconsistent placement of UV lamps relative to the printed web can lead to uneven curing.

- Uniform Coverage: Automated UV systems ensure that the UV light is applied uniformly across the entire width of the label. This eliminates the risk of partially cured areas or “shadows” that can occur with manual lamp positioning.

- Reduced Warping and Shrinkage: While less common, improper or excessive UV exposure can sometimes cause heat buildup leading to substrate warping or shrinkage, affecting label dimensions. Automated systems provide controlled energy application, mitigating these risks.

Applications in Different Printing Processes

The benefits of automated UV systems are realized across various label printing technologies:

Flexographic Printing

In flexographic printing, where flexible relief plates are used, precise ink transfer and immediate curing are essential. Automated UV systems ensure that the ink is instantly fixed after transfer, preventing ink spread and maintaining sharp detail. This is especially crucial for intricate graphics and small text commonly found on labels. The rapid curing also allows flexo presses to run at higher speeds, boosting productivity without compromising quality.

Offset Printing (Sheet-fed and Web)

While offset printing often deals with larger formats, its application in label production, particularly narrow web offset, also benefits from automation in UV curing. Automated UV units ensure that inks are fully cured before the sheet or web is handled, preventing smudging and enabling immediate post-press operations. This is critical for maintaining the pristine appearance of high-quality labels produced via offset.

Narrow Web Printing

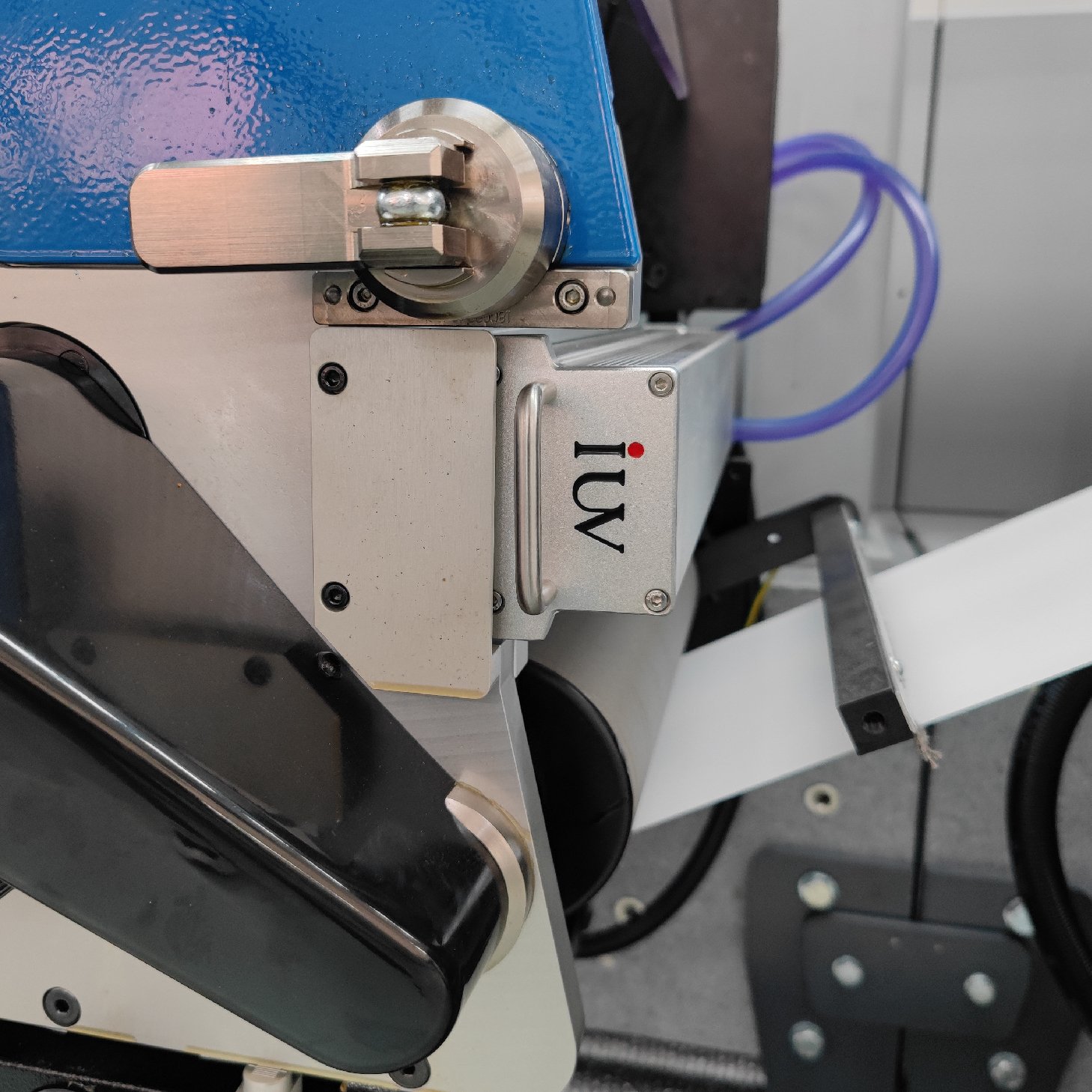

Narrow web presses are specifically designed for label and flexible packaging production. These presses often integrate multiple printing units and finishing processes inline. Automated UV curing systems are a natural fit here, allowing for rapid curing between units and at the end of the press. This inline capability is where automated UV truly shines in reducing manual handling and the opportunities for error. The ability to cure inks and coatings instantly between stations allows for complex multi-layer designs and inline finishing effects like spot varnishes, foils, and textured finishes, all while maintaining precision and minimizing errors.

Integrating Automation for Maximum Impact

The true power of automated UV systems lies in their integration into the overall production workflow. Beyond just the curing unit itself, automation encompasses:

- Automated Setup: Systems that can automatically adjust UV lamp power based on job parameters or sensor feedback.

- Inline Monitoring and Quality Control: Integration with vision systems that can detect curing-related defects in real-time and flag them, or even automatically adjust parameters.

- Predictive Maintenance: Sensors that monitor the health of UV lamps and components, alerting operators to potential issues before they cause production stoppages or quality problems.

By minimizing manual adjustments and providing consistent, controlled processing, automated UV systems directly address the root causes of many human errors in label production. This leads to higher quality labels, reduced waste, increased efficiency, and ultimately, greater profitability for label manufacturers. The shift towards automation in UV curing is not just a trend; it’s a strategic imperative for staying competitive in today’s demanding label market.