In the realm of high-quality printing, especially for labels and narrow-web applications, achieving impeccable registration is paramount. This isn’t just about aesthetics; it’s about functionality. Think about multi-layer labels, security features, or even just a clean, crisp brand message. Any misalignment, even by a fraction of a millimeter, can render a print job unusable, leading to costly waste and missed deadlines. The demand for ever-tighter tolerances in modern printing presses, particularly in flexographic and offset printing, necessitates sophisticated control systems.

The Role of UV Curing in Registration Accuracy

Traditionally, UV curing has been a game-changer for print speed and durability. However, the curing process itself can introduce variables that affect registration. As inks cure under UV light, they can undergo slight shrinkage or expansion. This thermal expansion and contraction, if not managed uniformly across the entire web, can lead to positional shifts of the printed image. This is where automated UV curing control steps in, transforming a potential source of registration error into a tool for enhancing precision.

Understanding LED UV Curing Technology

The shift from traditional mercury-vapor UV lamps to LED UV curing systems has been revolutionary. LED UV offers several key advantages relevant to registration control. Firstly, their instant on/off capability allows for precise control over the curing duration for each printed section. Secondly, LEDs emit a more focused spectrum of UV light, often tailored to specific ink formulations, leading to more efficient and consistent curing. Crucially, LEDs generate significantly less heat compared to mercury lamps. This reduced thermal load on the substrate minimizes the heat-induced shrinkage or expansion that can plague registration, especially on sensitive materials like thin films.

The Mechanics of Automated UV Curing Control

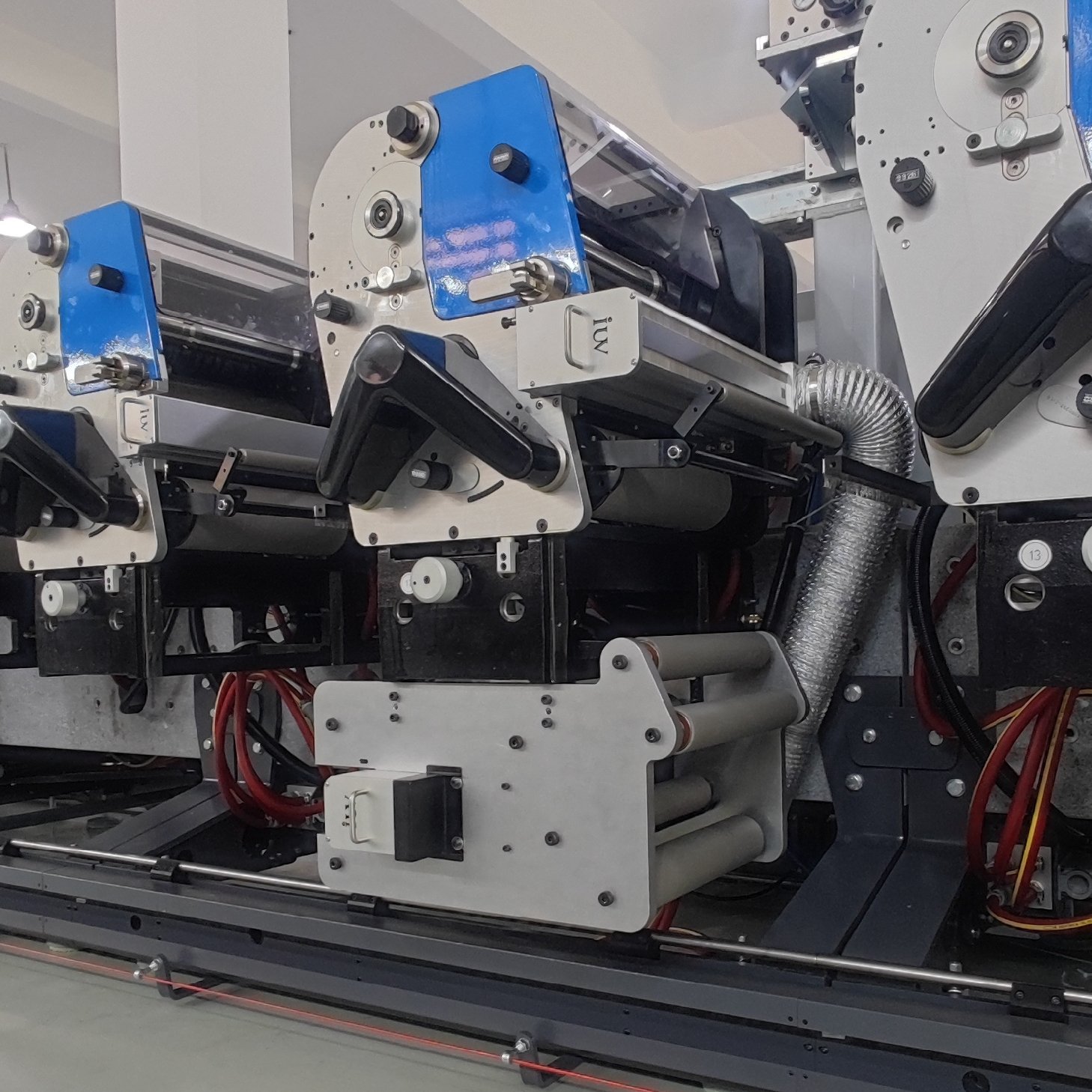

Automated UV curing control is not a single piece of technology but rather an integrated system. It combines advanced sensor technology, sophisticated control algorithms, and the precise delivery of UV energy. At its core, the system aims to ensure that the UV curing process is applied consistently and predictably across the entire width of the print web, at the exact moment of registration.

- Precise Wavelength and Intensity Control: Modern LED UV systems allow for fine-tuning of the UV wavelength and intensity. This ensures that the ink cures optimally without over-curing or under-curing, both of which can impact dimensional stability. Different ink formulations require specific UV energy levels for complete cure. An automated system can adjust these parameters on the fly based on press speed and ink type.

- Optimized Lamp Placement and Zoning: The physical placement of UV lamps relative to the printing units is critical. Automated systems often employ modular LED arrays that can be positioned optimally for each print station. Furthermore, these arrays can be divided into zones, allowing for targeted curing. This means that only the relevant areas of the web are exposed to UV light, and at the precise intensity and duration needed.

- Closed-Loop Feedback Systems: This is where the “automated” aspect truly shines. Sensors are employed to monitor various parameters in real-time. These might include web temperature, ink surface temperature, and even indicators of curing progress. This data is fed back into the control system, which then makes micro-adjustments to the UV lamp output, speed, or duration to maintain optimal curing conditions and, by extension, registration accuracy. For instance, if the web temperature rises slightly due to increased press speed, the system can automatically reduce the UV energy output or increase cooling to prevent shrinkage.

- Integration with Press Control Systems: The most effective automated UV curing control systems are seamlessly integrated with the main press control console. This allows for a holistic approach to print quality management. Operators can set parameters through a single interface, and the press and curing systems communicate to ensure optimal performance across all functions. This integration simplifies operation and reduces the likelihood of human error.

Benefits for Specific Printing Processes

The impact of automated UV curing control is particularly pronounced in certain printing sectors:

- Flexographic Printing (Flexo): In flexo, especially for narrow-web label printing, fast production speeds and the use of a wide range of substrates (paper, film, foil) are common. Precise registration is crucial for intricate designs, fine text, and multiple colors. Automated UV curing ensures that the ink cures quickly and uniformly on diverse substrates without causing them to distort, thereby preserving the registration achieved by the printing plates and anilox rollers.

- Offset Printing (Lithography): Sheetfed and web offset printing often deal with larger formats and high print volumes. For applications requiring perfect registration, such as folding cartons or high-end packaging labels, the heat generated by traditional curing methods can be problematic. LED UV’s low heat output combined with precise control minimizes these issues, maintaining the sharp definition and accurate color placement that offset is known for.

- Narrow-Web Printing: This is where the benefits are most acutely felt. Narrow-web presses, by their nature, demand high precision due to the limited width for error. Automated UV curing allows these presses to run at their maximum speeds while maintaining tight registration for labels, flexible packaging, and other specialized narrow-web products. The ability to control curing precisely on thin films is a significant advantage.

Eliminating Registration Challenges: A Proactive Approach

Instead of reacting to registration problems caused by curing, automated UV control makes it a proactive solution.

- Reduced Shrinkage and Expansion: By using low-heat LED technology and precisely controlling the UV energy delivered, the substrate experiences minimal thermal distortion. This directly preserves the physical positioning of the printed elements.

- Consistent Ink Laydown: Uniform curing ensures that the ink film remains dimensionally stable from the moment it’s applied. This prevents issues like dot gain variations or color shifts that can manifest as registration errors.

- Enabling Complex Jobs: With reliable registration control, printers can confidently take on more complex jobs. This includes multi-layer applications, inline finishing processes like foiling or embossing that require precise alignment, and variable data printing where each element must be perfectly placed.

- Waste Reduction and Throughput Increase: By eliminating registration-related waste and allowing presses to run at optimal speeds, automated UV curing control directly contributes to increased productivity and profitability. The reduction in make-ready time, as the curing process is less of a variable to troubleshoot, is also substantial.

The Future of Precision Printing

As printing technology continues to advance, the integration of automated UV curing control will become even more sophisticated. We’re likely to see AI-driven systems that can predict and compensate for potential registration issues before they even occur, based on historical data and real-time sensor input. The drive towards greater sustainability also plays a role; efficient LED UV curing uses less energy and avoids the need for certain solvent-based or heat-set inks, further streamlining the printing process.

In conclusion, achieving precise material registration with automated UV curing control isn’t just an incremental improvement; it’s a fundamental shift in how printing operations can achieve unparalleled quality and efficiency. It’s a testament to how intelligent application of technology can solve complex challenges, making previously difficult or impossible print jobs a routine reality, especially within the demanding landscape of label and narrow-web printing.