Efficient narrow-web digital label production demands streamlined workflows. Automation plays a pivotal role in achieving this efficiency. When coupled with advanced curing technologies like LED UV, the benefits multiply. This discussion will explore how workflow automation, specifically within the context of narrow-web printing and LED UV curing, enhances productivity and output quality.

The Evolving Landscape of Narrow-Web Label Printing

The narrow-web label market is dynamic. Brands continuously seek innovative ways to differentiate their products on the shelf. This translates to a growing demand for shorter runs, faster turnarounds, and complex embellishments. Traditional printing methods, while still relevant, can struggle to meet these evolving needs without significant manual intervention. This is where digital printing and automation become indispensable.

Digital printing technologies have revolutionized label production. They eliminate the need for physical plates, drastically reducing setup times and costs. This is particularly beneficial for the short-run, variable-data printing that is increasingly common. However, the true potential of digital printing is unlocked when integrated into an automated workflow.

Understanding Workflow Automation in Label Production

Workflow automation refers to the use of technology to manage and execute a series of tasks with minimal human intervention. In label printing, this encompasses everything from order entry and pre-press to printing, finishing, and shipping. A fully automated workflow aims to eliminate bottlenecks, reduce errors, and optimize resource allocation.

For narrow-web digital label production, automation can address several key areas. Order management systems can automatically receive and process incoming jobs. Pre-press software can check artwork for errors, optimize it for digital printing, and manage color profiles. Print management information systems (MIS) can track job progress, material usage, and machine performance. And finally, automated finishing equipment can seamlessly handle cutting, slitting, and rewinding.

The Role of Digital Printing in Automation

Digital printing inherently lends itself to automation. Unlike conventional methods, digital presses can switch between jobs rapidly without the need for plate changes. This allows for a more fluid production schedule, where multiple short runs can be processed consecutively. Variable data printing, a hallmark of digital, is also inherently automated, allowing for personalized labels without manual intervention for each design variation.

Furthermore, digital presses often come with advanced software integration capabilities. This allows them to communicate directly with MIS and pre-press systems, providing real-time data and control. This interconnectedness is the foundation of a truly automated workflow.

The Advantages of Workflow Automation

Implementing workflow automation in narrow-web digital label printing yields significant advantages. Firstly, it drastically reduces human error. Manual data entry and job setup are prone to mistakes that can lead to costly reprints. Automation minimizes these risks.

Secondly, automation accelerates turnaround times. By eliminating manual steps and streamlining processes, jobs can move from order to completion much faster. This is a critical competitive advantage in today’s fast-paced market.

Thirdly, automation improves resource utilization. By optimizing job scheduling and reducing downtime, printing presses and other equipment are used more effectively. This leads to higher overall productivity and profitability.

Finally, automation enhances quality consistency. Automated systems ensure that parameters are set correctly for each job, leading to consistent print quality across all runs.

Introducing LED UV Curing Technology

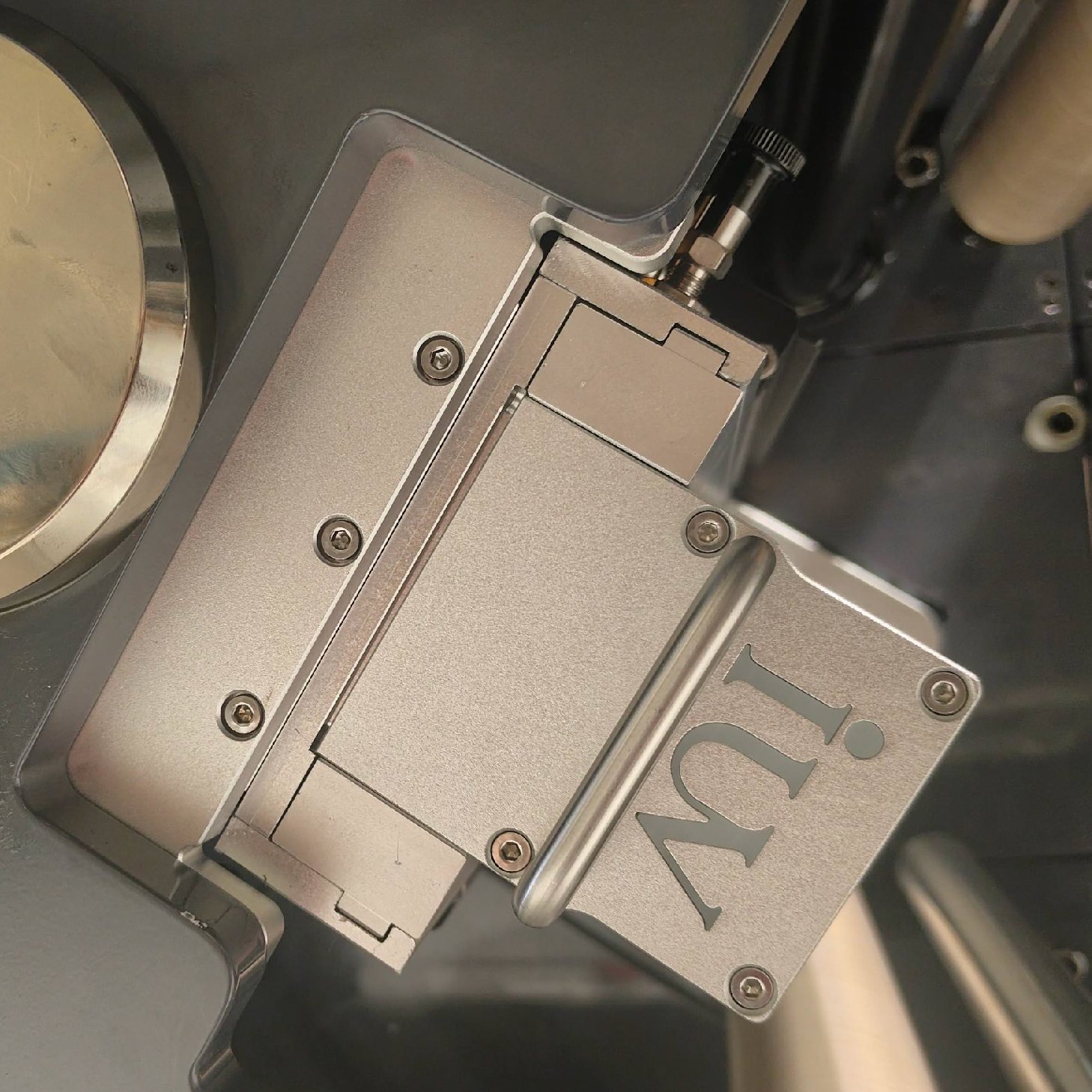

Complementing workflow automation is the advancement in curing technology. LED UV curing has emerged as a superior alternative to traditional mercury lamp UV curing and other drying methods. It offers a host of benefits that align perfectly with the demands of efficient label production.

LED UV curing utilizes light-emitting diodes to generate ultraviolet light. This light initiates a photochemical reaction, rapidly curing the ink or coating. Unlike mercury lamps, LEDs offer instant on/off capabilities, significantly longer lifespans, and reduced heat output.

Benefits of LED UV Curing in Narrow-Web Printing

For narrow-web digital label printers, LED UV curing offers several distinct advantages. One of the most significant is energy efficiency. LEDs consume considerably less power than mercury lamps, leading to lower operational costs. They also generate less heat, which is crucial for sensitive substrates and helps maintain a stable printing environment.

Another key benefit is the instantaneous curing. This allows for faster printing speeds, as the ink is fully cured immediately after application. This eliminates the need for lengthy drying tunnels and reduces the risk of smudging or ink transfer. The instant cure also enables inline finishing operations, further enhancing workflow efficiency.

LED UV inks and coatings are also known for their durability and vibrant color reproduction. They offer excellent scratch resistance, chemical resistance, and weatherability, meeting the demanding requirements for various label applications.

Integrating LED UV Curing into Automated Workflows

The seamless integration of LED UV curing into automated workflows is straightforward. Because LED UV systems can be turned on and off instantly, they are perfectly suited for the variable demands of digital printing. A digital press can transition from one job to another, and the LED UV lamps can activate only when needed, without the warm-up and cool-down times associated with mercury lamps.

This on-demand curing capability directly contributes to energy savings and reduces wear and tear on the lamps. Furthermore, the immediate curing allows for faster throughput between the printing unit and the finishing station, a critical component of an automated line.

Specific Applications and Considerations

When considering workflow automation and LED UV curing for narrow-web digital label production, specific applications warrant attention. For instance, food and beverage labels often require high-quality graphics and durability. LED UV inks provide the necessary vibrancy and resistance to environmental factors.

Pharmaceutical labels, with their stringent regulatory requirements and need for variable data like batch numbers and expiry dates, benefit immensely from the precision of digital printing and the speed offered by LED UV curing. The ability to automate the printing of this variable data with high accuracy is paramount.

Challenges and Solutions in Automation

While the benefits of workflow automation are clear, implementation can present challenges. Initial investment in software and hardware can be substantial. However, the long-term savings in labor, material waste, and increased throughput typically provide a strong return on investment.

Another challenge can be the integration of disparate systems. Ensuring compatibility between different software platforms and hardware components is crucial. Partnering with experienced vendors who offer integrated solutions can mitigate this risk.

Training staff on new automated systems is also important. A well-trained workforce is essential for maximizing the benefits of automation. Continuous training and development ensure that operators can effectively manage and maintain the automated workflow.

The Future of Narrow-Web Label Production

The future of narrow-web label production is undoubtedly digital and automated. The convergence of advanced digital printing technology, sophisticated workflow automation, and efficient curing methods like LED UV is paving the way for unprecedented levels of productivity, quality, and flexibility.

As brands continue to demand more customized, eye-catching, and rapidly produced labels, printers who embrace these technologies will be best positioned to succeed. The ability to efficiently manage complex jobs, reduce waste, and deliver high-quality results on time will be the defining factors in this competitive market.

Workflow automation, powered by the speed and efficiency of digital printing and the robust performance of LED UV curing, represents the forefront of narrow-web label production. Embracing these advancements is not just about staying current; it’s about defining the future of the industry.