In the dynamic beverage and cosmetic industries, labels are more than just product identifiers; they are critical brand ambassadors. The demand for eye-catching, durable, and precisely printed labels is ever-increasing. Meeting this demand efficiently and cost-effectively often hinges on advanced printing technologies. High-speed narrow-web digital printing, particularly when combined with cutting-edge LED UV curing, offers a compelling solution for label converters serving these competitive markets.

This technology excels in producing short to medium runs of labels with exceptional quality and speed. The “narrow-web” aspect refers to the web width, typically ranging from 4 to 20 inches, which is ideal for the dimensions of most product labels. Digital printing eliminates the need for traditional printing plates, significantly reducing setup times and costs, especially for jobs with frequent design changes or variable data requirements.

The Digital Advantage in Label Printing

Traditional printing methods like flexography and offset lithography have long been mainstays in label production. Flexography, with its raised-relief plates and fast printing speeds, is well-suited for long runs and a variety of substrates. Offset lithography, on the other hand, provides excellent ink transfer and fine detail, often used for high-quality graphics. However, both methods involve significant make-ready times associated with plate production and press setup.

Digital printing bypasses this entirely. Instead of plates, it uses inkjet technology to deposit ink directly onto the substrate based on digital artwork. This means that switching between different label designs can happen in minutes, not hours. For beverage brands that frequently introduce seasonal products or limited editions, or for cosmetic companies refreshing their packaging, this agility is invaluable. It allows for faster time-to-market and the ability to produce highly customized or personalized labels.

Furthermore, digital printing inherently supports variable data printing (VDP). This capability allows each label to carry unique information, such as serial numbers, barcodes, QR codes, or even personalized messages. This is a powerful tool for brand owners seeking to enhance traceability, implement promotional campaigns, or engage consumers on a more personal level.

Exploring High-Speed Narrow-Web Capabilities

The “high-speed” aspect of modern narrow-web digital presses is a testament to significant engineering advancements. These machines are designed for maximum throughput, often achieving speeds comparable to or exceeding those of conventional printing methods for shorter runs. This is achieved through sophisticated printhead technology, optimized ink delivery systems, and robust web handling capabilities.

The precision of narrow-web printing is crucial for labels. Intricate designs, fine text, and detailed graphics demand accurate ink placement and consistent color reproduction. Digital inkjet heads, with their ability to control individual ink droplets, deliver this precision. Modern presses offer high resolutions, ensuring that even the smallest details are rendered sharply.

The range of substrates that can be printed on narrow-web digital presses is also impressive. From various paper stocks and films (like BOPP, PET, and PE) to specialized materials, these presses can handle a diverse array of label applications. This versatility is essential for beverage and cosmetic products, which often require labels with specific tactile qualities, chemical resistance, or adhesion properties.

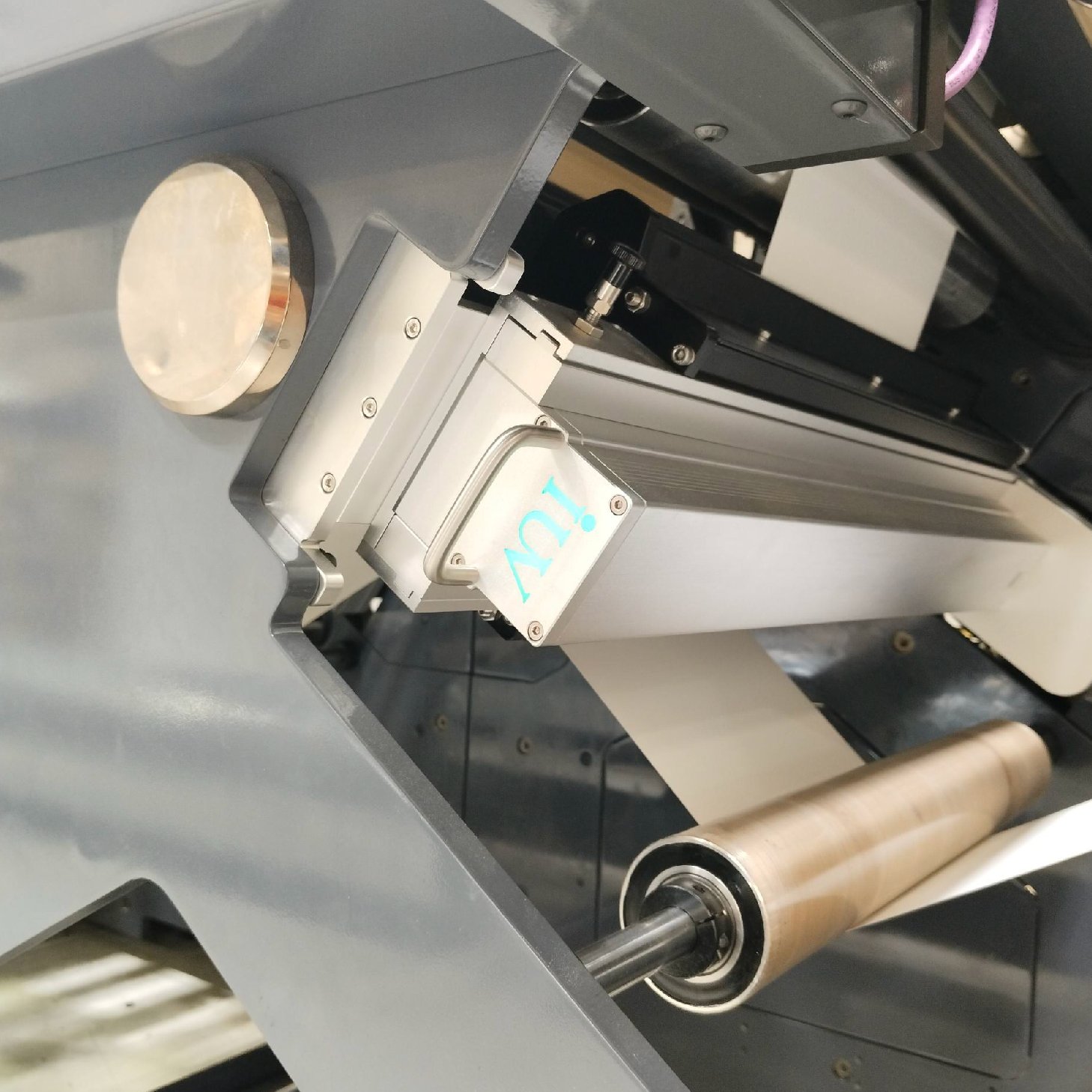

The Game-Changing Role of LED UV Curing

A critical component that enables high-speed digital printing is the curing technology. Traditionally, UV curing has been used, employing mercury vapor lamps. However, LED UV curing has emerged as a superior alternative, offering significant advantages for label converters.

UV curing works by using ultraviolet light to instantly polymerize (cure) ink, coating, or adhesive. This process transforms the liquid ink into a solid, durable film almost instantaneously. For high-speed printing, this rapid curing is non-negotiable. It prevents ink from smudging or transferring onto subsequent rollers or webs, allowing the press to run at maximum speed.

LED UV curing systems offer several distinct benefits over traditional mercury lamps:

- Energy Efficiency: LEDs consume significantly less energy, leading to lower operating costs and a reduced environmental footprint.

- Instant On/Off: Unlike mercury lamps that require warm-up and cool-down periods, LEDs can be switched on and off instantly. This saves energy and allows for precise curing control, especially important for intricate designs or when running at variable speeds.

- Longer Lifespan: LED lamps have a much longer operational life than mercury lamps, reducing maintenance and replacement costs.

- Lower Heat Emission: LEDs emit less heat, which is beneficial for heat-sensitive substrates often used in label printing, preventing warping or distortion.

- Mercury-Free: LEDs are environmentally friendly as they do not contain mercury, simplifying disposal and handling.

- Compact Size: The compact nature of LED UV curing systems allows for easier integration into narrow-web printing presses, often in smaller, more targeted curing zones.

The synergy between high-speed digital printing and LED UV curing is profound. The speed of the press is directly supported by the instantaneous and efficient curing provided by LED technology. This combination allows for a streamlined production process where jobs are printed, cured, and ready for finishing in a single pass.

Applications in Beverage and Cosmetics

For the beverage sector, labels often face demanding conditions. They might be exposed to moisture, condensation, abrasion, and varying temperatures. The durable, chemically resistant finish provided by UV-cured inks is a perfect match for these challenges. Whether it’s for water bottles, craft beer cans, wine bottles, or spirits, the label needs to maintain its integrity and visual appeal from the production line to the consumer’s hands. High-speed digital printing with LED UV curing allows for rapid production of these durable labels, meeting seasonal demands and promotional needs efficiently.

In the cosmetics industry, aesthetics are paramount. Labels on perfumes, skincare, and makeup products must exude quality and luxury. Digital printing’s ability to reproduce vibrant colors, fine details, and special effects (like metallic inks or spot varnishes) is crucial. Furthermore, cosmetic labels often require resistance to oils, creams, and other personal care product ingredients. The robust cure provided by LED UV ink ensures that the printed design remains intact and visually appealing, enhancing the premium feel of the product. The flexibility of digital also supports smaller batch production for niche beauty products or personalized gift sets.

Optimizing Workflow and Cost-Effectiveness

The integration of high-speed narrow-web digital printing with LED UV curing offers significant workflow improvements and cost-effectiveness, especially for label converters dealing with shorter runs and frequent job changes.

- Reduced Lead Times: The elimination of plate production and faster setup directly translates to shorter lead times for customers. This can be a significant competitive differentiator.

- Lower Waste: Digital printing generally produces less material waste during setup compared to conventional methods.

- Inventory Management: The ability to print on demand reduces the need for large inventories of pre-printed labels, minimizing obsolescence and storage costs.

- Profitability on Short Runs: Digital printing makes short to medium runs economically viable, opening up new market opportunities and serving a broader range of client needs.

- On-Site Production: For some businesses, the agility of digital printing allows for more localized or even on-site label production, further reducing logistics costs and turnaround times.

As the beverage and cosmetic industries continue to innovate and demand greater customization and faster market entry, the role of high-speed narrow-web digital printing, powered by efficient LED UV curing, will only become more pronounced. It represents a forward-thinking approach to label production, ensuring quality, speed, and flexibility in a highly competitive landscape.