The narrow-web label printing industry is experiencing a significant evolution. For years, flexographic printing has been the workhorse, delivering high speeds and consistent quality for long runs. However, the increasing demand for shorter print runs, customization, and faster turnaround times has pushed converters to explore new technologies. This is where the integration of digital and flexo printing, often referred to as hybrid printing, comes into play. This powerful combination leverages the strengths of both technologies to create a versatile and efficient production workflow.

Understanding the Core Technologies: Flexo and Digital

Flexographic printing, or flexo, is a direct printing method that uses a flexible relief plate. Ink is transferred from an anilox roll to the raised image areas of the plate, and then directly to the substrate. Its advantages include high speed, excellent ink transfer, and the ability to print on a wide variety of substrates, from paper to films. Flexo is particularly well-suited for long production runs where consistent color and quality are paramount.

Digital printing, on the other hand, applies images directly from a digital file without the need for traditional printing plates. Technologies like inkjet and electrophotography are common. Digital printing excels in variable data printing (VDP), short runs, and rapid prototyping. Its key benefit is eliminating the setup time and cost associated with plates, making it economically viable for smaller quantities and jobs requiring personalization.

The Case for Hybrid: Bridging the Gap

The beauty of a hybrid narrow-web press lies in its ability to combine these complementary technologies within a single machine. This allows printers to seamlessly switch between or integrate flexo and digital printing units. For example, a job might start with flexo units for standard process colors or special effects inks, followed by digital units for variable data or spot colors. This approach optimizes the production process, allowing for the most cost-effective and efficient method for each aspect of the print job.

This integration is particularly impactful in the narrow-web label sector, where space is often at a premium and the demand for diverse, short-run jobs is high. A hybrid press can handle everything from a simple, high-volume label printed entirely by flexo to a complex, personalized label that utilizes both flexo and digital capabilities.

The Role of UV Curing in Modern Printing

A critical component in maximizing the benefits of both flexo and digital printing, especially in narrow-web applications, is UV (ultraviolet) curing technology. Traditional inks and coatings require drying time through evaporation, which can slow down production and limit substrate choices. UV curing, however, uses UV light to instantly polymerize inks and coatings, transforming them from a liquid to a solid, durable film.

LED UV Curing: The Next Generation of Drying

While traditional mercury-based UV lamps have been the standard, Light Emitting Diode (LED) UV curing systems are rapidly becoming the preferred choice. LED UV offers several compelling advantages that align perfectly with the demands of modern hybrid printing:

- Instant On/Off: LEDs require no warm-up time, allowing for immediate printing and stopping, which is ideal for the stop-and-go nature of some digital print heads and for job changeovers.

- Energy Efficiency: LEDs consume significantly less energy compared to mercury lamps, leading to lower operational costs and a reduced carbon footprint.

- Longer Lifespan: LED lamps have a much longer operational life, reducing maintenance and replacement costs.

- Lower Heat Emission: LEDs emit very little heat onto the substrate. This is crucial for printing on heat-sensitive materials like thin films, preventing distortion or damage.

- Wavelength Specificity: LED systems can be tailored to specific UV wavelengths, optimizing curing for a wider range of inks and coatings.

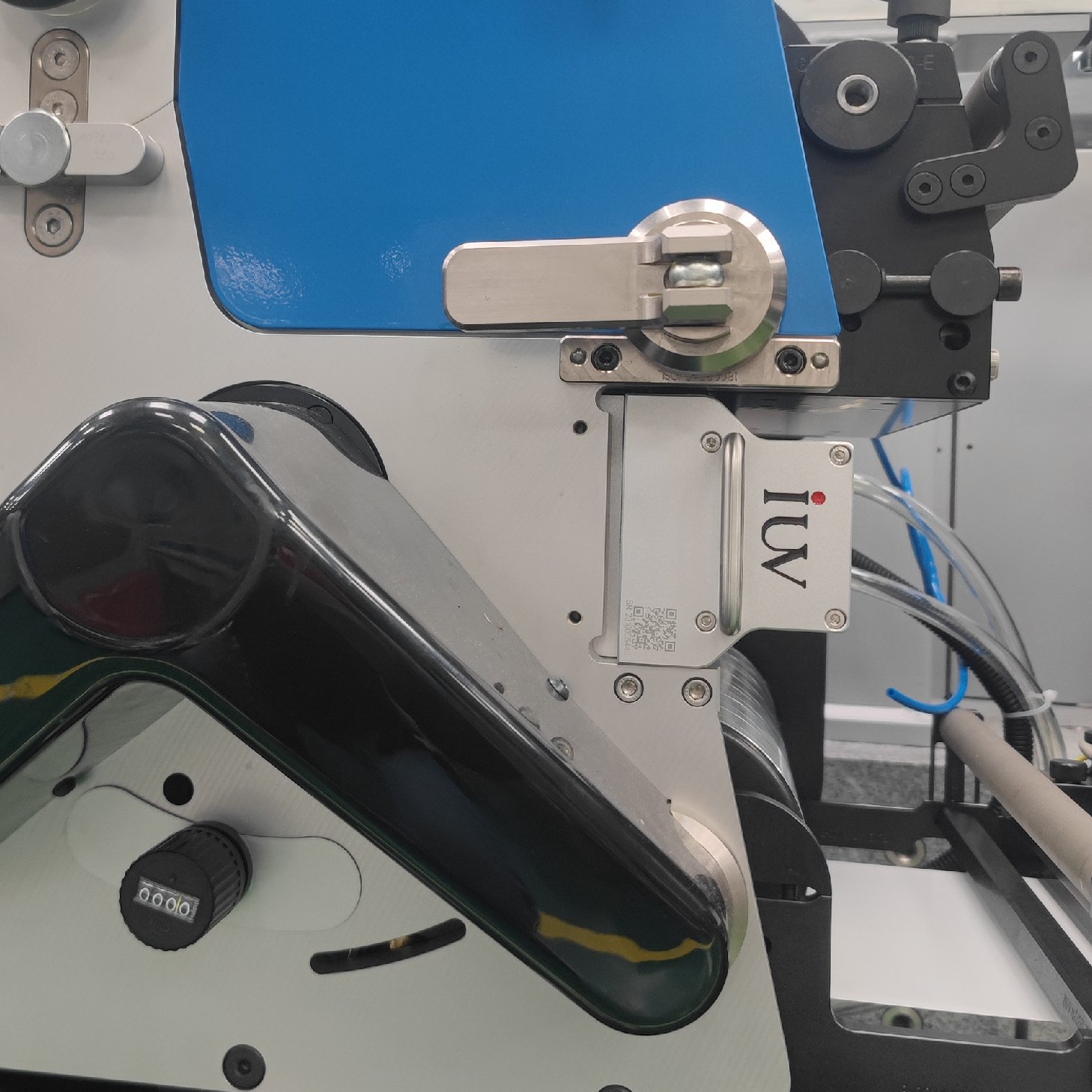

Integrating LED UV in Hybrid Presses

In a hybrid narrow-web setup, LED UV curing units can be strategically placed after each printing station, whether it’s a flexo station or a digital unit. This ensures that inks and coatings are instantly cured, preventing smudging and allowing for immediate handling and further processing.

For flexo stations, an LED UV unit following the printing cylinder allows for fast curing of process colors, spot colors, or overprint varnishes, enabling immediate transfer to the next station or the rewinder. Similarly, after digital printing heads, an LED UV dryer ensures that the applied ink is instantly cured before any subsequent printing or finishing operations. This immediate curing is essential for maintaining print quality, preventing ink transfer between layers, and achieving the desired tactile and visual effects.

Benefits of LED UV in Narrow-Web Hybrid Printing

The synergy between hybrid printing and LED UV curing unlocks several key advantages for narrow-web label converters:

- Enhanced Substrate Versatility: The low heat emission of LED UV allows for printing on a wider array of sensitive substrates, including thin films, foils, and even some heat-sensitive papers, without compromising quality.

- Improved Print Quality and Durability: Instant curing with LED UV leads to sharper dot definition, better ink adhesion, and superior scratch and chemical resistance. This is vital for labels that need to withstand harsh environments or frequent handling.

- Increased Production Speeds: By eliminating drying time, LED UV curing allows presses to run at maximum speeds, significantly boosting throughput. This is particularly beneficial when combining fast flexo printing with digital processes.

- Reduced Waste and Downtime: The precise and instant nature of LED UV curing minimizes ink smudging and errors, leading to less waste. The instant on/off capability also contributes to less downtime during job changes.

- Environmental Advantages: The energy efficiency of LED UV systems contributes to lower power consumption, aligning with sustainability goals.

- Expanded Application Possibilities: Hybrid presses equipped with LED UV can handle a vast range of label applications, from simple product labels to complex, high-value labels requiring special effects, variable data, and specialized finishes. This includes applications in food and beverage, pharmaceuticals, cosmetics, and industrial sectors.

Workflow Optimization with Hybrid Technology

Consider a scenario where a brand needs 5,000 labels for a new product launch. The design includes standard brand colors, a unique serial number for each batch, and a special metallic effect on the logo.

A hybrid narrow-web press with LED UV curing can tackle this efficiently:

- Flexo for Base Colors and Effects: The initial flexo stations can lay down the primary brand colors and apply the metallic ink for the logo. Each flexo station is followed by an LED UV curing unit to instantly cure the ink.

- Digital for Variable Data: The digital printing unit then comes into play, printing the unique serial numbers for each batch directly onto the label. An LED UV unit cures the variable data ink immediately.

- Finishing: The press can then move to a finishing station, such as a die-cutting unit, where the labels are accurately cut. If a protective coating is desired, a flexo unit with a UV-curable varnish and another LED UV dryer can be incorporated before the final die-cut.

This integrated process means the entire job is completed in a single pass, reducing handling, minimizing setup, and ensuring consistent quality throughout.

The Future is Hybrid and LED UV

The trend towards shorter runs, increased personalization, and faster market entry is undeniable. For narrow-web label converters, embracing hybrid printing technology, particularly when powered by efficient and versatile LED UV curing, is not just an advantage – it’s becoming a necessity for staying competitive. The ability to seamlessly blend the proven strengths of flexo with the agility of digital, all while benefiting from the speed and consistency of LED UV, positions label printers for success in an ever-evolving market. This integrated approach offers unparalleled flexibility, efficiency, and the capability to meet the most demanding customer requirements.