When it comes to achieving brilliant, durable prints on modern, high-speed flexographic presses, the curing technology plays a pivotal role. For decades, mercury vapor lamps have been the go-to solution for UV curing. However, a new contender, UV LED technology, is rapidly gaining traction. For narrow-web printers focused on labels and flexible packaging, understanding the nuances between these two technologies is crucial for optimizing performance, reducing costs, and enhancing print quality.

The fundamental goal of UV curing is to instantly solidify liquid inks, coatings, and adhesives as they pass through the printing unit. This process relies on UV light activating photoinitiators within the ink formulation. These initiators, in turn, trigger a rapid polymerization reaction, transforming the liquid into a solid, cured film. High-speed printing demands a curing system that can keep pace without compromising ink adhesion, gloss, or scratch resistance.

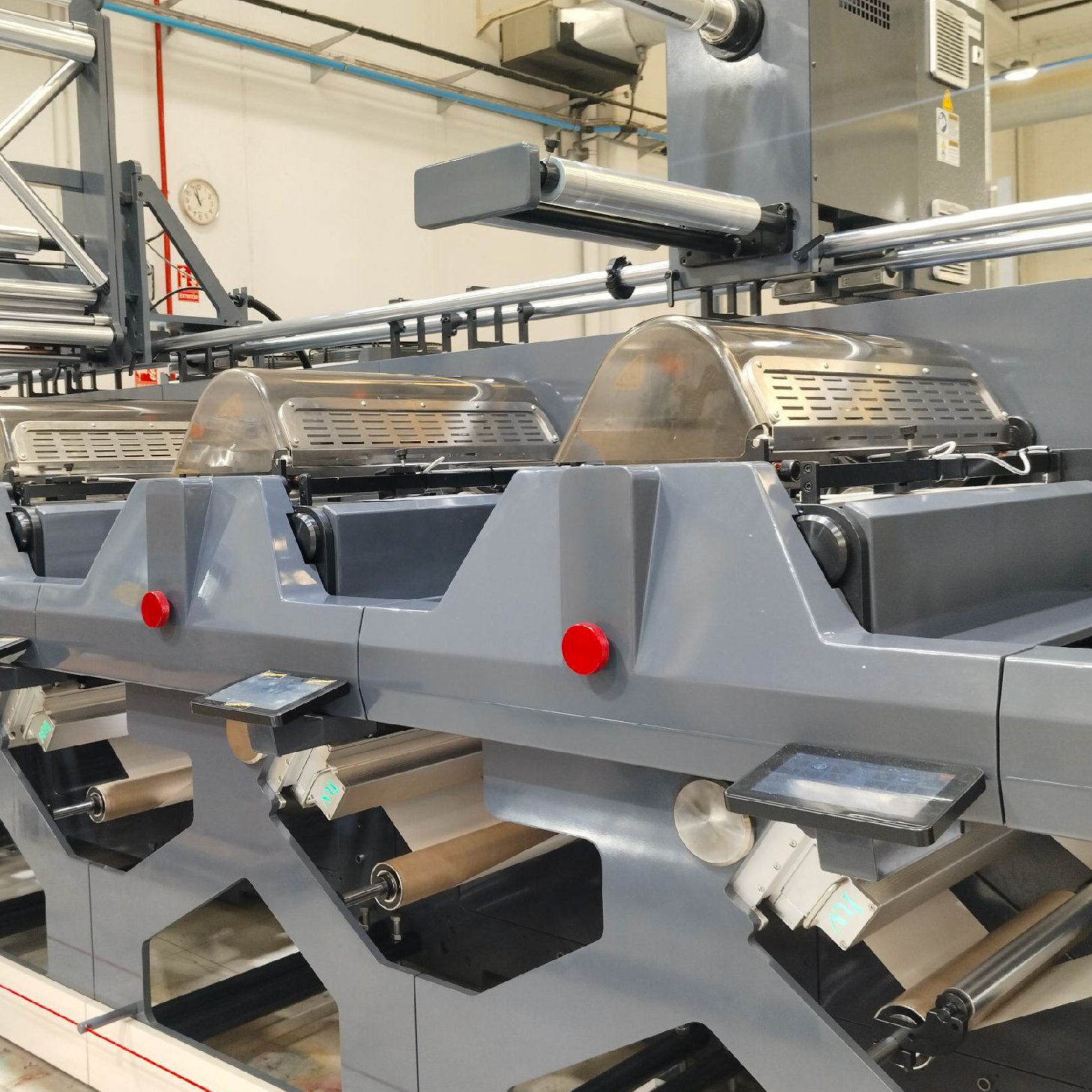

The Traditional Workhorse: Mercury Vapor UV Lamps

Mercury vapor lamps have powered UV curing in the printing industry for a long time. They operate by passing an electric current through mercury vapor, which emits UV light across a broad spectrum. This broad-spectrum output means they can cure a wide range of UV-curable inks and coatings, including those with less sensitive photoinitiator packages.

One of the primary advantages of mercury lamps is their lower initial capital investment. Compared to their LED counterparts, mercury lamp systems are generally less expensive to purchase upfront. They also offer a high peak irradiance, which can be beneficial for certain demanding applications. For printers with existing mercury-based systems, the transition to new technology can seem daunting and costly.

However, mercury lamps come with several significant drawbacks. They generate a considerable amount of heat, which can impact the substrate temperature, particularly on sensitive films. This heat can lead to warping, delamination, or changes in material properties. Furthermore, mercury lamps have a finite lifespan and require regular replacement, typically every 800 to 1,500 hours of operation. This downtime for lamp changes adds to operational costs and reduces press availability.

The broad spectrum emitted by mercury lamps also means they produce a lot of heat as a byproduct, which is not utilized for curing. This wasted energy contributes to higher electricity consumption. Moreover, mercury lamps contain hazardous materials, posing disposal challenges and environmental concerns. Their warm-up and cool-down cycles also add to the overall process time, which can be a bottleneck in a high-speed printing environment.

The Emerging Innovator: UV LED Curing Technology

UV LED curing systems utilize light-emitting diodes (LEDs) to produce UV light. Unlike mercury lamps that emit a broad spectrum, LEDs emit UV light at very specific, narrow wavelengths. This targeted output is a key differentiator. Common wavelengths for UV LED curing in printing include 365 nm, 385 nm, 395 nm, and 405 nm.

The primary advantage of UV LED technology is its energy efficiency. LEDs convert a much higher percentage of electrical energy into UV light, resulting in significantly lower power consumption compared to mercury lamps. This translates directly into reduced operating costs and a smaller carbon footprint. For label printers running multiple shifts, these energy savings can be substantial over the lifespan of the equipment.

Another major benefit is the minimal heat transfer to the substrate. Because LEDs emit light in a narrow spectrum and do not rely on heating a filament, they generate very little infrared heat. This makes them ideal for curing heat-sensitive substrates like thin films, some plastics, and delicate papers, preventing distortion and maintaining material integrity. This is particularly important in the narrow-web sector where material versatility is key.

UV LED systems also boast an exceptionally long operational lifespan, often exceeding 20,000 hours. This dramatically reduces maintenance downtime and the frequency of component replacements, leading to higher press uptime and greater productivity. The “instant on/off” capability of LEDs means there are no warm-up or cool-down periods, allowing for immediate start-stop operation which is perfectly suited for the stop-and-go nature of many flexo printing processes.

Key Considerations for High-Speed Flexo Presses

When evaluating UV LED versus mercury UV for high-speed flexo presses, several critical factors come into play.

Ink and Coating Compatibility

This is perhaps the most significant difference to address. Traditional mercury lamps, with their broad UV spectrum, can cure a wide array of inks and coatings formulated with various photoinitiators. UV LED systems, however, require inks and coatings specifically formulated to be cured by their targeted wavelengths. This means printers transitioning to LED technology may need to work closely with their ink suppliers to ensure they have access to compatible formulations. Fortunately, the market for LED-curable inks and coatings has expanded dramatically, offering robust options for most label and packaging applications.

Spectral Output and Curing Depth

Mercury lamps emit light across a wide range of UV wavelengths, including UV-A, UV-B, and UV-C. This broad spectrum can penetrate deeper into thicker ink layers, which can be advantageous for certain applications. UV LEDs, on the other hand, emit light in narrow bands, typically in the UV-A range. While some LED systems can be configured with multiple wavelengths to mimic a broader spectrum or achieve deeper cure, printers must ensure the chosen LED system and ink are optimized for the required curing depth and ink film thickness.

Irradiance and Speed

Irradiance, the intensity of UV light delivered to the substrate, is critical for achieving fast curing speeds. High-speed flexo presses demand high irradiance to ensure complete cure at speeds exceeding hundreds of feet per minute. Mercury lamps can achieve high peak irradiance but often at the cost of significant heat generation. Modern UV LED systems can offer very high irradiance levels at their specific wavelengths, and because they don’t generate excess heat, they can be positioned closer to the substrate for more efficient energy transfer. The development of high-power LED arrays has closed the gap considerably, allowing LED systems to meet the demands of even the fastest presses.

Energy Consumption and Operational Costs

As mentioned, UV LED technology is vastly more energy-efficient. This translates into lower electricity bills, a significant operating expense for any print shop. While the initial investment for UV LED systems can be higher, the long-term savings in energy consumption, reduced maintenance, and fewer lamp replacements often result in a lower total cost of ownership. For businesses focused on sustainability and reducing their environmental impact, the energy efficiency of LEDs is a compelling factor.

Heat Management and Substrate Limitations

The minimal heat output from UV LEDs is a game-changer, especially for narrow-web printers working with a variety of substrates. Sensitive films, thin papers, and plastics can be printed at high speeds without the risk of heat-induced distortion or damage. Mercury lamps, conversely, can heat the substrate considerably, requiring additional cooling systems, which further increases energy consumption and complexity.

Environmental Impact and Safety

Mercury vapor lamps contain hazardous mercury, requiring careful handling, disposal, and adherence to environmental regulations. UV LED systems are mercury-free, making them a safer and more environmentally friendly option. The reduced energy consumption of LEDs also contributes to a lower carbon footprint.

Making the Choice for Your Press

For high-speed narrow-web flexo presses, UV LED curing technology presents a compelling future. Its superior energy efficiency, long lifespan, minimal heat output, and instant on/off capability align perfectly with the demands of modern label and packaging production. While the initial investment might be higher, the long-term operational savings and performance benefits often make it the more economical and effective choice.

Printers considering a switch should engage with their ink manufacturers to ensure a smooth transition and select UV LED systems that provide the appropriate wavelength and irradiance for their specific applications. The advancements in LED technology and ink formulations mean that UV LED is no longer a niche solution but a powerful, efficient, and sustainable option for high-speed flexographic printing.

The decision between UV LED and mercury UV ultimately depends on a printer’s specific needs, substrate types, ink requirements, and budget considerations. However, the clear trend towards efficiency, sustainability, and advanced performance points strongly towards UV LED as the superior technology for the future of high-speed flexo printing.