The relentless pursuit of efficiency in modern printing demands speed. In the narrow web label sector, high-speed printing systems are no longer a luxury but a necessity. However, pushing these presses to their limits can introduce significant challenges, particularly concerning ink drying. Incomplete ink drying can lead to a cascade of problems, including smudging, poor adhesion, increased waste, and ultimately, dissatisfied customers. Fortunately, the integration of high-speed UV flexo printing systems, coupled with advanced LED UV curing technology, offers a powerful solution to mitigate these ink drying issues.

Understanding the Drying Challenges in High-Speed Printing

At higher press speeds, the time available for ink to dry between printing stations becomes critically short. Traditional drying methods, such as heat-set or air drying, often struggle to keep pace. This is especially true with UV-curable inks, which rely on a photochemical reaction to solidify. If the UV energy isn’t applied efficiently or comprehensively, the ink may not cure properly before the next process step or rewind.

Several factors contribute to these drying challenges:

- Ink Viscosity and Rheology: The flow properties of the ink play a crucial role. Thicker inks require more energy and time to dry. At high speeds, ink can be subjected to significant shear forces, potentially altering its behavior.

- Substrate Absorbency: Porous substrates allow ink to penetrate, aiding drying. However, non-absorbent films, commonly used in label printing, demand surface curing. Insufficient surface curing leads to issues.

- Ink Layer Thickness: Thicker ink layers naturally take longer to dry. Printing at high speeds can sometimes lead to heavier ink deposits if not carefully controlled.

- Ambient Conditions: Temperature and humidity in the printing environment can influence drying rates, although this is less of a factor with UV curing.

- UV Lamp Performance: The intensity, wavelength, and uniformity of the UV light source are paramount for effective curing. Degrading lamps or improper positioning can lead to incomplete curing.

The Power of UV Flexo Printing Systems

Flexographic printing, often referred to as flexo, is a workhorse in the label industry. Its ability to print on a wide range of substrates, including flexible films and foils, makes it ideal for packaging and labels. When combined with UV-curable inks and advanced UV curing technology, flexo printing offers distinct advantages for high-speed operations.

UV-curable inks are formulated with monomers, oligomers, photoinitiators, and pigments. Upon exposure to specific wavelengths of UV light, the photoinitiators absorb the energy and generate free radicals or cations. These reactive species then initiate a rapid polymerization process, cross-linking the monomers and oligomers into a solid, durable film. This process is virtually instantaneous, making it perfectly suited for high-speed printing.

Advantages of LED UV Curing in High-Speed Flexo

While traditional mercury vapor UV lamps have been the standard, the advent of LED UV curing technology has revolutionized the industry, especially for high-speed flexo applications. LED UV lamps offer a host of benefits that directly address drying issues:

- Instant On/Off Capability: Unlike mercury lamps that require warm-up and cool-down periods, LEDs are instant. This eliminates wasted energy and allows for precise control over curing, even at the highest press speeds.

- Consistent Output: LEDs provide a stable and consistent UV output throughout their lifespan. This ensures uniform curing from the first label to the last, reducing variability and waste.

- Specific Wavelengths: LEDs can be engineered to emit specific wavelengths of UV light that are highly efficient for curing particular ink formulations. This targeted energy delivery optimizes the curing process.

- Lower Heat Emission: Compared to mercury lamps, LEDs generate significantly less heat. This is crucial for printing on heat-sensitive substrates, preventing distortion and ensuring dimensional stability. It also creates a more comfortable working environment.

- Energy Efficiency: LEDs consume considerably less power than traditional UV lamps, leading to substantial cost savings on energy bills.

- Longer Lifespan: LEDs have a much longer operational life than mercury lamps, reducing downtime and replacement costs.

Optimizing UV Curing for High-Speed Flexo

To effectively reduce ink drying issues in high-speed UV flexo printing, a holistic approach is necessary. This involves carefully selecting materials, optimizing press settings, and ensuring the curing system is configured correctly.

Ink Formulation and Selection

The choice of UV-curable ink is paramount. Look for inks specifically designed for high-speed flexo applications and compatible with LED UV curing.

- Low-Viscosity Inks: These inks flow more easily and require less energy to cure.

- Fast-Curing Formulations: Ink manufacturers offer formulations with optimized photoinitiator packages for rapid polymerization.

- LED-Specific Inks: These inks are designed to absorb light efficiently within the specific wavelength output of LED UV lamps.

Substrate Considerations

The substrate dictates the curing requirements. Non-absorbent films require efficient surface curing.

- Surface Energy: Ensure the substrate has adequate surface energy for ink adhesion. Corona treatment can be used to enhance this.

- Substrate Type: For challenging films, consider inks and curing systems specifically engineered for them.

Press and Curing System Setup

This is where the real optimization happens.

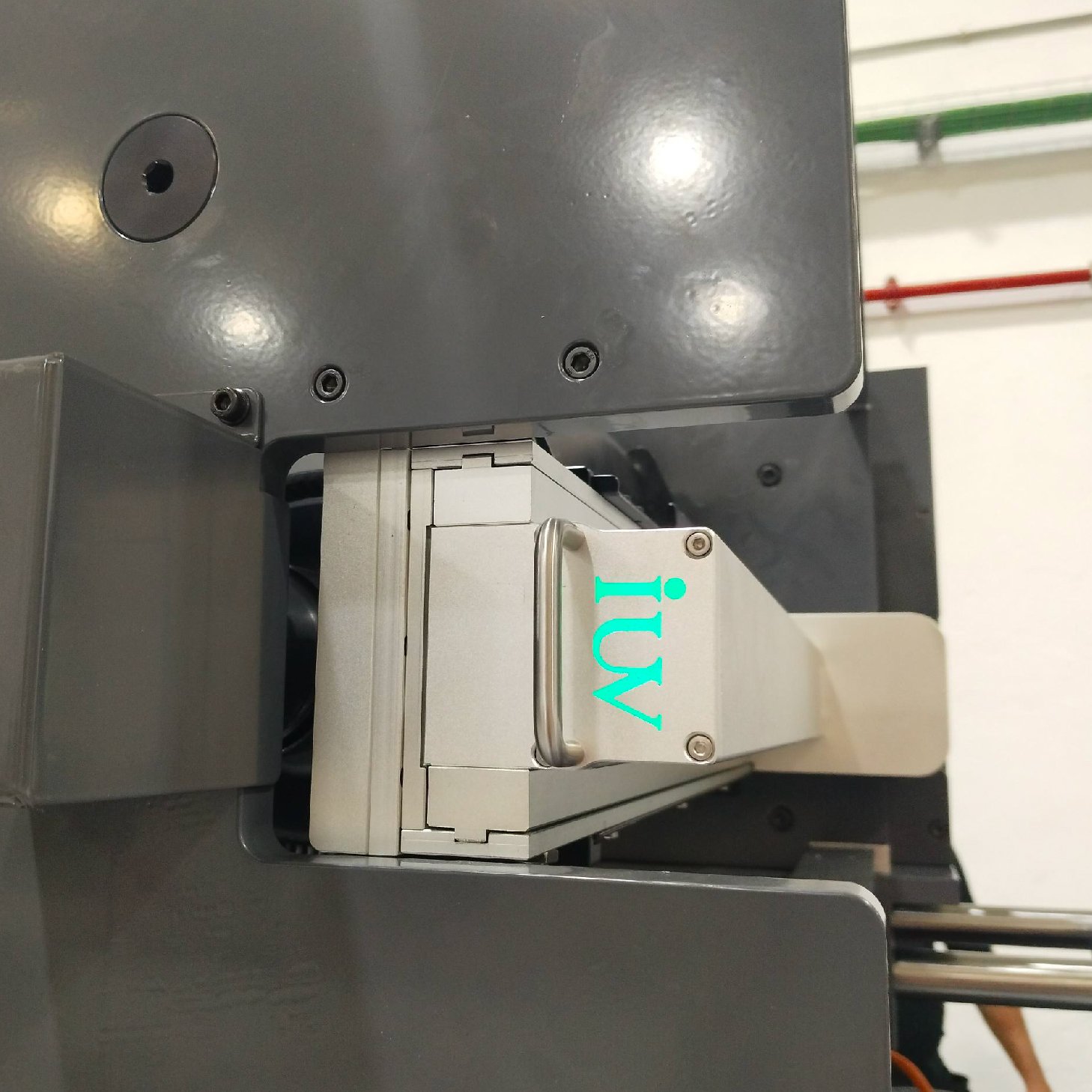

- UV Lamp Placement: Position the LED UV lamps as close as possible to the printing stations without interfering with ink transfer or causing substrate damage. Proper inline or inter-deck placement is critical.

- UV Intensity: The intensity of the UV light, measured in milliwatts per square centimeter (mW/cm²), must be sufficient to initiate and complete the polymerization reaction within the available dwell time. Consult ink and UV system manufacturers for recommended intensity levels.

- Dose (Energy): The total energy delivered is the product of intensity and exposure time. At high speeds, the exposure time is reduced, so higher intensity becomes essential. The required UV dose depends on the ink formulation and substrate.

- Wavelength Matching: Ensure the UV wavelength emitted by the LEDs matches the absorption spectrum of the photoinitiators in the ink. Common LED wavelengths used are 365nm, 385nm, 395nm, and 405nm.

- Cooling Systems: While LEDs generate less heat, a proper cooling system for the lamps and the press is still important for maintaining optimal operating temperatures and preventing ink viscosity changes.

- Dwell Time: This refers to the time the ink is exposed to UV light. At higher press speeds, the dwell time decreases. This necessitates a more powerful and efficient curing system.

- Ink Transfer Control: Precise anilox roll selection, ink viscosity control, and doctor blade settings are crucial to ensure a consistent and appropriate ink laydown. Over-inking can lead to drying problems.

- Web Path Optimization: Minimize the distance between the printing unit and the UV dryer. A shorter, direct web path ensures the ink doesn’t have excessive time to spread or react prematurely.

Troubleshooting Common Ink Drying Issues

When problems arise, a systematic approach to troubleshooting is key:

- Smudging or Rubbing: This is a clear indicator of incomplete curing.

- Check UV intensity and dose: Are the lamps performing optimally? Is the energy output sufficient for the ink and speed?

- Verify wavelength compatibility: Is the LED output matching the ink’s photoinitiators?

- Assess ink laydown: Is too much ink being applied?

- Examine substrate treatment: Is the surface energy adequate for ink adhesion?

- Poor Adhesion: The ink lifts off the substrate.

- Re-evaluate UV curing: Ensure thorough polymerization has occurred.

- Check surface preparation: Is the substrate clean and properly treated?

- Consider ink formulation: Is the ink designed for the specific substrate?

- Drying Marks or Streaks: Uneven drying across the printed area.

- Uniformity of UV light: Is the UV output consistent across the entire web width? Check for any blocked or malfunctioning LEDs.

- Ink viscosity variations: Ensure consistent ink viscosity throughout the run.

- Anilox roll issues: Are there any blockages or wear on the anilox?

The Future of High-Speed UV Flexo

The continuous evolution of UV-curable inks and LED UV curing technology promises even greater capabilities for high-speed narrow web printing. As energy efficiency, spectral control, and ink formulations become more sophisticated, the challenges associated with drying at extreme speeds will continue to diminish.

By understanding the intricate interplay between ink, substrate, press dynamics, and curing technology, printers can leverage high-speed UV flexo systems to achieve unparalleled productivity and quality. The investment in a robust LED UV curing system, coupled with a proactive approach to material selection and press optimization, is a strategic move to overcome ink drying hurdles and stay ahead in the competitive label printing market. It’s about achieving that perfect, instantaneous cure, every single time, no matter how fast the press is running.