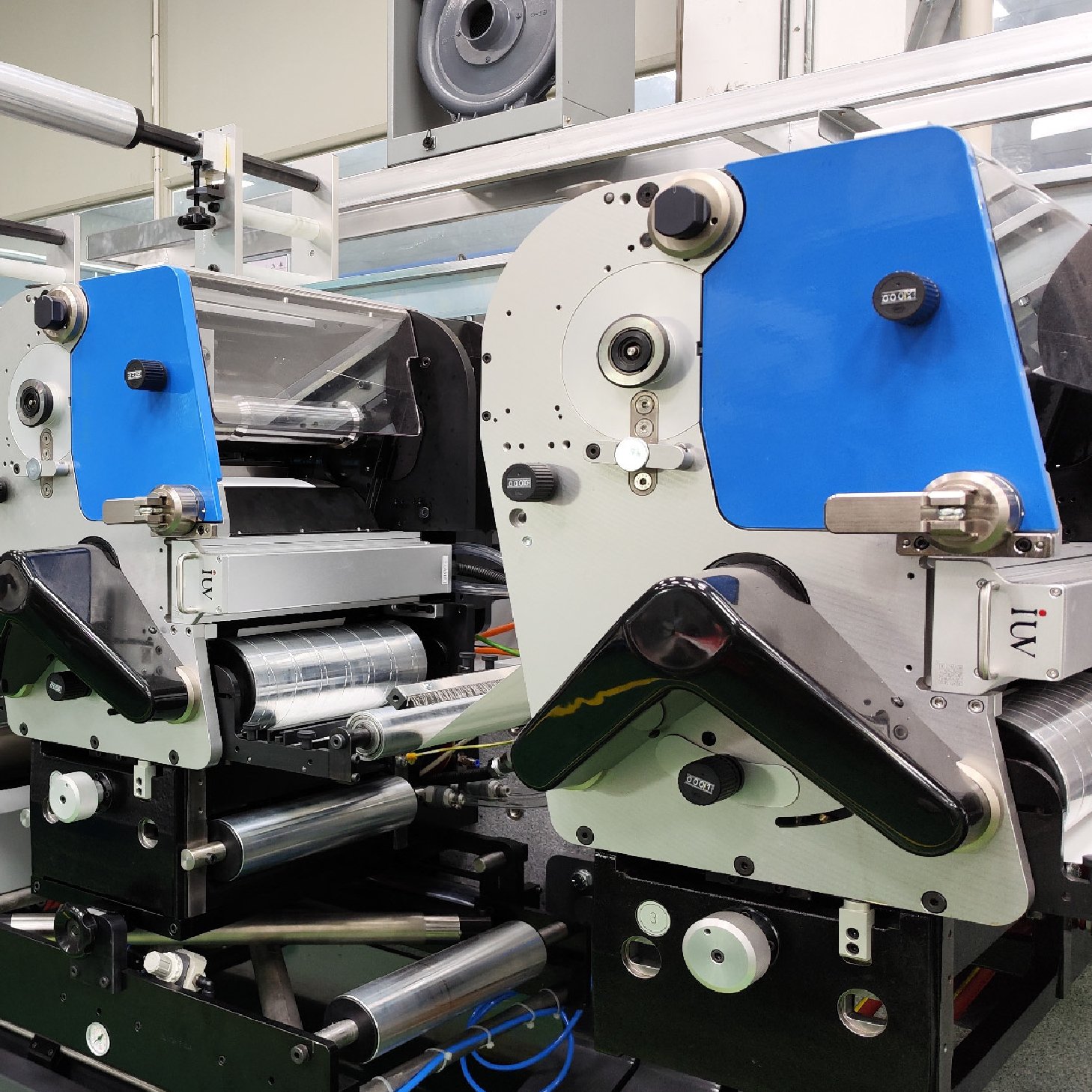

In the dynamic world of narrow web printing, especially within the label and flexible packaging sectors, achieving consistent, high-quality results is paramount. Precision offset printing plates are at the heart of this process, and their performance is intrinsically linked to the UV inks they interact with. Optimizing UV ink performance goes beyond simply selecting an ink; it involves a deep understanding of the interplay between ink chemistry, plate technology, and the critical UV curing process. This article delves into the nuances of maximizing UV ink efficiency for superior offset printing plate applications.

Understanding UV Ink Chemistry and Plate Interaction

UV-curable inks are formulated with photoinitiators, monomers, oligomers, and pigments. When exposed to specific wavelengths of UV light, photoinitiators absorb energy and generate free radicals. These radicals then initiate a rapid polymerization chain reaction, transforming the liquid ink into a solid, durable film. The success of this transformation hinges on how well the ink’s components interact with the relief image on the offset printing plate.

For precision offset plates, particularly those used in narrow web applications, the characteristics of the plate material are crucial. Whether it’s a photopolymer or a metal-backed plate, its surface energy, ink receptivity, and resistance to the printing environment directly influence ink transfer and laydown. Inks formulated for offset printing must possess the right viscosity and rheology to transfer cleanly from the plate to the substrate without excessive dot gain or plugging of fine details. Poor ink-to-plate compatibility can lead to premature plate wear, inconsistent ink density, and compromised print resolution, directly impacting the final label or packaging.

The Role of LED UV Curing in Ink Performance

The transition from traditional mercury vapor lamps to LED UV curing systems has revolutionized the printing industry, offering significant advantages in energy efficiency, heat management, and operational control. However, optimizing UV ink performance with LED UV curing requires a tailored approach. LED systems emit light at specific, narrow wavelengths. This means that the photoinitiator package within the UV ink must be precisely matched to the emission spectrum of the LED lamps.

If the photoinitiators do not efficiently absorb the emitted UV light, the polymerization process will be incomplete, leading to under-cured ink. This can manifest as poor rub resistance, insufficient adhesion, and a tendency for inks to “kick back” or offset onto subsequent elements. Conversely, an ink with an optimal photoinitiator system for the specific LED wavelength will cure rapidly and thoroughly, ensuring a robust and durable print finish. This precise matching is especially critical in high-speed narrow web printing, where dwell times under the UV lamps are minimal.

Optimizing Ink Transfer and Dot Gain in Offset Plates

In offset printing, achieving sharp, well-defined dots is a hallmark of quality. UV inks, with their rapid curing properties, offer a distinct advantage in controlling dot gain. Unlike conventional inks that rely on solvent evaporation, UV inks solidify almost instantaneously upon curing. This minimizes the ink’s ability to spread laterally on the substrate after transfer from the plate, thereby preserving the integrity of fine details and halftones.

To fully leverage this, the ink’s rheology must be finely tuned. An ink that is too fluid may spread too much before curing, even with UV technology, leading to enlarged dots and loss of crispness. Conversely, an ink that is too viscous might not transfer efficiently from the plate, resulting in weak dots and insufficient ink coverage. Experienced formulators work closely with printers to adjust viscosity, thixotropy, and surface tension to achieve optimal ink transfer and minimize unwanted dot gain. This ensures that the high resolution capabilities of precision offset printing plates are fully realized.

Substrate Compatibility and Ink Adhesion

The choice of substrate is a critical factor influencing UV ink performance. Different materials, from coated papers and films to foils, possess varying surface energies and porosity. UV inks need to exhibit excellent adhesion to a wide range of substrates to prevent delamination, scratching, or rub-off. This is achieved through careful formulation of the ink’s resin system and the inclusion of adhesion promoters.

For narrow web printing, which often deals with challenging filmic substrates, specialized UV ink formulations are essential. These inks are designed to wet the substrate effectively and form a strong bond upon curing. Inadequate adhesion can lead to costly reprints and brand damage. Therefore, thorough testing of UV ink performance on the intended substrate under actual printing conditions is an indispensable step in the optimization process.

Managing Heat and UV Energy During Curing

While LED UV curing systems generate significantly less heat than older technologies, heat management remains a consideration, particularly in high-speed narrow web printing. Excessive heat can affect the substrate’s dimensional stability and, in some cases, pre-maturely cure or degrade certain ink components. Conversely, insufficient UV energy, whether due to lamp intensity issues or improper setup, will result in incomplete curing.

Precisely controlling the UV energy output (irradiance) and the duration of exposure (dose) is key. This requires careful calibration of the UV curing system and selection of inks that are formulated to cure effectively within the available energy window. For printers using LED UV, understanding the specific wavelength and power output of their lamps is crucial for selecting compatible inks and optimizing the curing process to achieve maximum ink performance and durability.

Troubleshooting Common UV Ink Performance Issues

When UV ink performance falters in precision offset printing, a systematic troubleshooting approach is necessary. Common issues include:

- Poor Adhesion: This can stem from an incompatible ink formulation, contaminated substrate surface, or insufficient UV energy. Thorough cleaning of the substrate and verifying the ink’s adhesion promoters and UV cure are initial steps.

- Incomplete Cure (Ink Tackiness): Often caused by an incorrect photoinitiator package for the UV light source, insufficient UV dose, or the presence of UV absorbers in the ink or on the substrate that block light penetration. Checking photoinitiator compatibility with the LED spectrum and ensuring adequate UV energy delivery are vital.

- Excessive Dot Gain: This can be related to ink rheology that is too fluid, plate issues, or incorrect impressão pressure. Adjusting ink viscosity and rheological properties, along with checking plate condition and press settings, can help.

- Ink Transfer Problems: This might indicate an ink viscosity that is too high or too low, or issues with the printing plate’s surface characteristics. Fine-tuning the ink’s flow properties and ensuring the plate is clean and free from contaminants are important.

- Blocking (Ink Transferring to Backside of Next Sheet/Roll): This is typically a sign of incomplete curing or insufficient slip properties in the ink. Verifying full cure and ensuring the ink has adequate slip additives are key.

The Future of UV Ink and Offset Plate Integration

As printing technology advances, the synergy between UV inks and precision offset printing plates will continue to deepen. Innovations in ink chemistry are leading to formulations with enhanced performance characteristics, such as improved scratch and chemical resistance, faster cure speeds, and greater sustainability. Simultaneously, advancements in plate manufacturing are producing plates with finer detail reproduction, superior ink release, and extended run lengths.

For printers in the label and narrow web markets, staying abreast of these developments is crucial. By understanding the intricate relationship between UV ink properties, LED UV curing technology, and the specific demands of precision offset printing plates, businesses can unlock new levels of print quality, efficiency, and competitive advantage. This informed approach ensures that every label and printed piece meets the highest standards of visual appeal and functional performance.