In the modern digital printing industry, the integration of LED UV curing systems has revolutionized print production, offering enhanced efficiency, energy savings, and superior print quality. LED UV curing is a transformative technology that has found its place across various printing applications, from flexographic to narrow-web printing. This article explores the growing use of LED UV curing systems in digital printing lines, focusing on their benefits, challenges, and the technical aspects of integrating this technology into existing print setups.

Understanding LED UV Curing Technology

LED UV curing is a process that uses ultraviolet light to instantly cure inks or coatings on substrates. The key advantage of LED UV systems over traditional UV systems is their ability to produce light at a specific wavelength using energy-efficient LED bulbs, rather than mercury vapor lamps. This results in faster curing times, less heat output, and lower energy consumption.

In the context of digital printing, LED UV curing systems are particularly beneficial because they enable printers to handle a broader range of substrates, including heat-sensitive materials, without the risk of distortion or damage. Additionally, LED UV ink is more environmentally friendly, offering lower emissions and reduced waste compared to conventional UV inks.

Benefits of LED UV Curing in Digital Printing

1. Faster Drying and Curing Time

The most immediate benefit of LED UV curing in digital printing is the speed at which it cures the printed material. Unlike traditional air-dried inks, which can take hours to fully cure, LED UV inks are cured within seconds. This speed significantly increases production efficiency, allowing printers to handle more jobs and meet tighter deadlines. Faster drying times also reduce the risk of smudging or fingerprints on printed products.

2. Energy Efficiency

One of the standout features of LED UV curing systems is their energy efficiency. Traditional UV lamps consume a considerable amount of power and generate a significant amount of heat, which requires additional cooling systems. LED UV lamps, in contrast, consume up to 80% less energy and generate less heat. This makes them more environmentally friendly and cost-effective, particularly for high-volume printing operations.

3. Better Print Quality and Durability

LED UV curing systems provide superior adhesion of inks to a wide variety of substrates, including non-porous materials like plastics, metals, and films. This is crucial for digital printing applications in flexible packaging, labels, and other areas where high durability and long-lasting prints are required. LED UV inks also produce vivid, high-quality images that resist fading, scratches, and smudging over time.

4. Versatility Across Substrates

Digital printing with LED UV curing is suitable for a wide range of substrates. Whether printing on coated or uncoated paper, synthetic materials, or even textured surfaces, LED UV ink adheres well, providing consistent results across different print jobs. This versatility makes LED UV curing particularly useful in applications such as flexible packaging, label printing, and short-run commercial printing.

The Integration Process in Digital Printing Lines

Integrating LED UV curing systems into existing digital printing lines requires careful consideration of both the hardware and the software involved. While some digital presses come with built-in UV curing units, others may require retrofitting with additional curing modules.

1. Print Head Compatibility

The first step in integrating LED UV curing into a digital press is ensuring compatibility with the print heads. Modern digital presses, particularly those using inkjet technology, are often designed to work with UV inks, including LED UV ink formulations. This compatibility ensures that the ink can be applied smoothly, cured effectively, and adheres properly to the substrate. If the press does not support LED UV ink, retrofitting the press may involve replacing or adjusting print heads to accommodate the new ink.

2. UV Curing Unit Installation

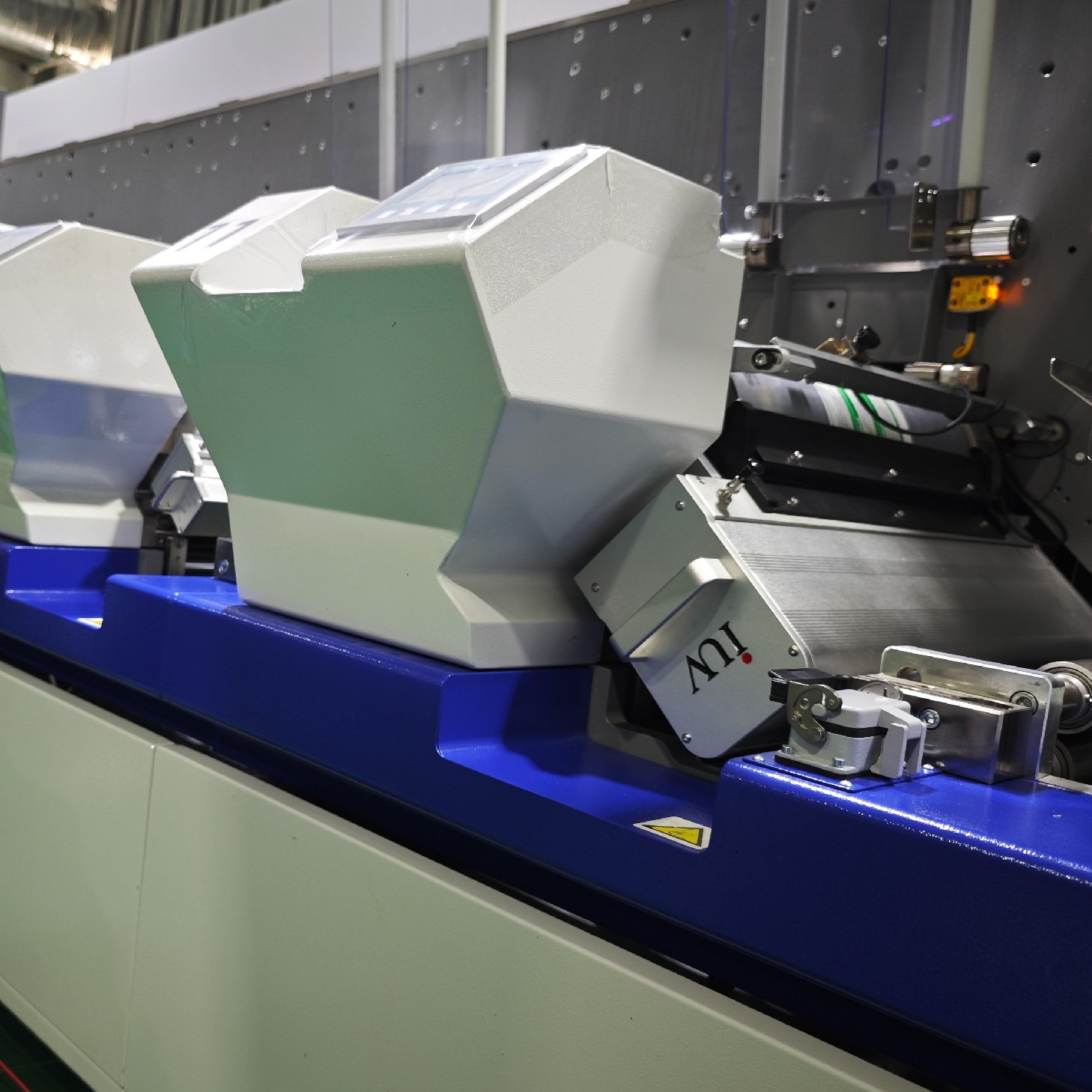

LED UV curing units are typically installed after the print head, where the ink passes through a curing zone. The curing unit uses LED lamps to emit UV light that instantly polymerizes the ink, making it dry and hard. The installation of LED UV curing units can vary depending on the type of press and the speed of the production line. For narrow-web printing applications, such as label printing, smaller, high-intensity LED curing systems may be used. For larger, more complex presses, multiple curing units may be integrated to ensure that each pass of the printed substrate is properly cured.

3. Adjusting Ink Formulations

To fully optimize the benefits of LED UV curing, it is often necessary to use specially formulated LED UV inks. These inks are designed to cure effectively under LED light, whereas traditional UV inks may require different wavelengths of UV light to cure properly. LED UV inks tend to have lower viscosity, which means they flow more easily and are suitable for high-speed digital printing. As a result, printers must work closely with ink manufacturers to select the best ink for their specific application.

Challenges in Adopting LED UV Curing Systems

While LED UV curing brings numerous benefits, there are some challenges associated with its adoption, particularly for companies that are new to the technology.

1. Initial Setup Costs

The cost of installing LED UV curing units can be a barrier for some businesses, particularly those with older printing equipment. Retrofitting an existing press with LED UV technology often requires significant investment in hardware, including the curing system itself, as well as changes to the ink delivery system and print heads. However, over time, the energy savings and increased efficiency can offset the initial setup costs.

2. Maintenance and Longevity

LED UV curing systems generally have a longer lifespan than traditional UV lamps, but they still require regular maintenance to ensure optimal performance. The LEDs themselves can last for tens of thousands of hours, but other components, such as reflectors and cooling systems, may need to be replaced more frequently. Regular maintenance is crucial to prevent downtime and maintain the efficiency of the curing process.

3. Ink Compatibility

Not all ink formulations are compatible with LED UV curing. Printers must ensure that the LED UV inks they use are designed to cure under the specific wavelength of light emitted by the LED lamps. Some substrates may also require pre-treatment or special coatings to ensure optimal ink adhesion. Printers may need to experiment with different ink formulations and curing settings to achieve the desired results.

Conclusion

The integration of LED UV curing systems in digital printing lines represents a significant advancement in printing technology. With faster curing times, energy efficiency, and superior print quality, LED UV systems have become an essential tool for modern printers looking to stay competitive in a fast-evolving market. Whether in flexographic printing, narrow-web printing, or label production, LED UV curing technology offers substantial benefits, making it a key part of the future of digital printing. By overcoming the initial challenges of integration and ensuring the proper setup and maintenance, printers can unlock the full potential of this cutting-edge technology, leading to more efficient production processes, lower costs, and higher-quality outputs.