Printing on flexible packaging materials presents unique challenges. Achieving fast, efficient, and high-quality curing is paramount. This is where advanced LED UV curing systems truly shine.

Traditional UV curing methods often involve mercury vapor lamps. These lamps have drawbacks, including high energy consumption, ozone production, and a limited lifespan. Furthermore, their spectral output can be broad, leading to inefficient energy transfer and potential substrate damage. The demands of modern flexible packaging printing necessitate a more sophisticated solution.

The Advantages of LED UV Curing for Flexible Packaging

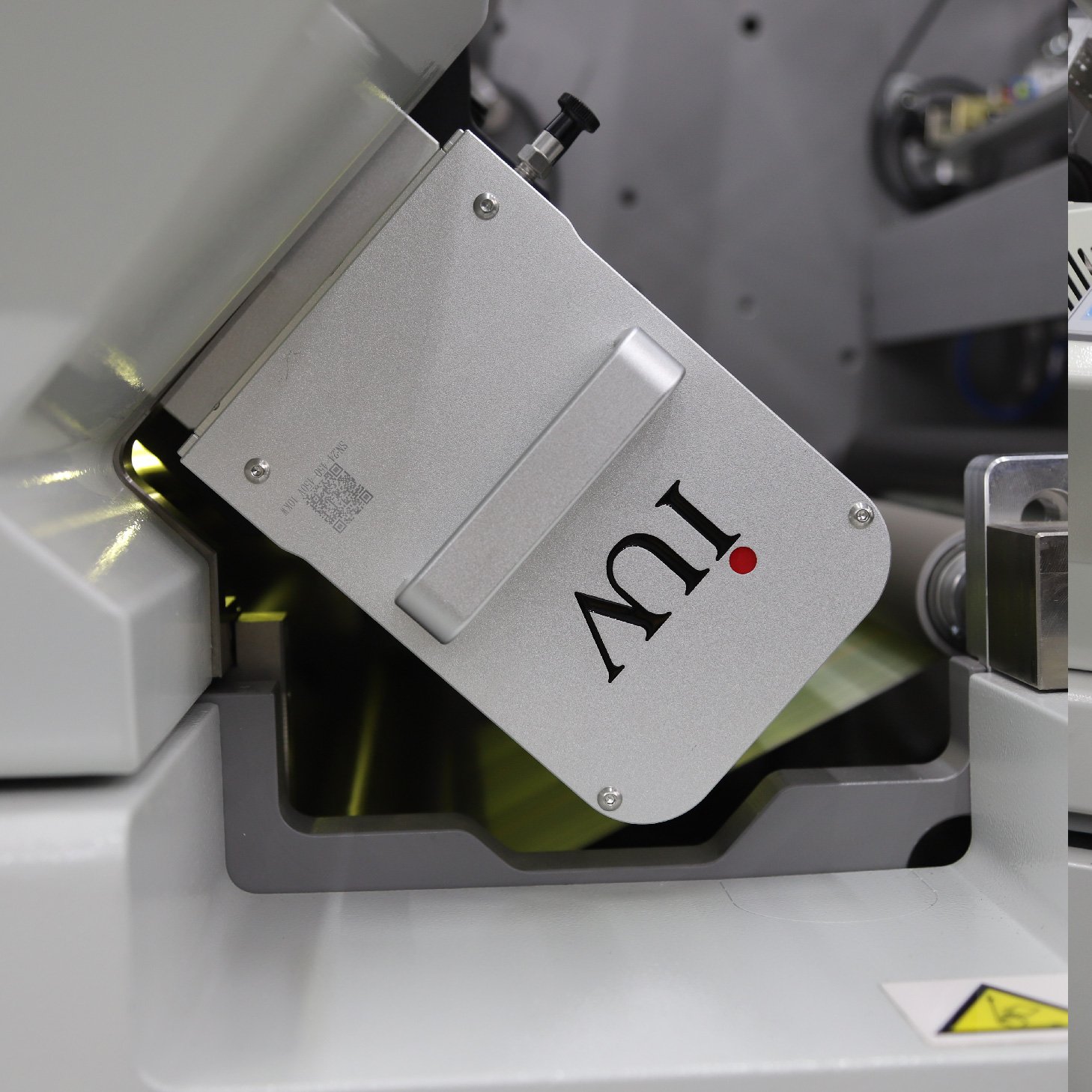

LED UV curing systems offer a transformative approach. They utilize light-emitting diodes (LEDs) to generate UV light. This technology brings a host of benefits specifically tailored to the needs of flexible packaging.

One significant advantage is energy efficiency. LEDs consume considerably less power than conventional mercury lamps. This reduction translates directly into lower operating costs for printing companies. The targeted spectral output of LEDs also means more energy is used for the actual curing process, minimizing waste.

Another key benefit is the extended lifespan of LED lamps. While mercury lamps may need replacement after a few thousand hours, LED systems can operate for tens of thousands of hours. This longevity reduces downtime and maintenance costs, contributing to overall operational productivity.

Precise Wavelength Control and Substrate Compatibility

A defining feature of LED UV curing is its precise wavelength control. LEDs can be engineered to emit specific UV wavelengths, typically in the UVA (315–400 nm) and sometimes UVB (280–315 nm) ranges. This precision is critical for optimizing the curing of various UV-curable inks and coatings used in flexible packaging.

For flexible packaging, substrates are often heat-sensitive. Traditional curing methods can generate significant heat, potentially deforming or damaging the material. LED UV systems, however, produce very little heat. This “cool cure” capability is invaluable when printing on delicate films like PET, BOPP, and PE, which are commonly used in food and beverage packaging.

The lower heat output also allows for faster printing speeds. Without the risk of overheating the substrate, printers can push their presses to higher throughputs, increasing their capacity and competitiveness.

Optimizing Curing for Different Printing Processes

LED UV curing is highly adaptable and works seamlessly with various printing technologies prevalent in flexible packaging.

Flexographic Printing: Flexography is a dominant force in narrow-web and wider-web flexible packaging. LED UV curing systems integrate exceptionally well with flexo presses. The fast curing speeds enable multiple print stations to apply different colors and effects without ink bleed or smudging. This is essential for producing vibrant, high-definition graphics that consumers expect. The precise curing also ensures excellent adhesion and rub resistance, critical for packaging that undergoes significant handling.

Gravure Printing: While less common for narrow-web flexible packaging, gravure is used for high-volume, wide-web applications. LED UV curing can be implemented in gravure lines to achieve rapid curing of specialized inks, particularly for spot colors or overprint varnishes. The efficiency of LED curing complements the speed of gravure presses.

Offset Printing (Sheetfed and Web Offset): For certain flexible packaging applications, particularly those requiring very fine detail or specific finishes, offset printing might be employed. LED UV curing is already a well-established technology in offset printing. Its application on flexible substrates ensures that high-quality, durable prints are achieved efficiently.

Digital Printing: As digital printing technologies gain traction in shorter runs and customization for flexible packaging, LED UV curing becomes an indispensable component. Digital inkjet printers rely on UV-curable inks, and LED systems provide the necessary instant cure to maintain print quality and substrate integrity.

Key Considerations When Implementing LED UV Systems

Selecting the right LED UV curing system involves several important factors.

Wavelength and Irradiance: The specific wavelength output of the LED system must match the photoinitiators within the UV-curable inks and coatings. Irradiance, the power density of the UV light, determines the speed of the curing reaction. Higher irradiance generally leads to faster curing. For flexible packaging, a balance is needed to ensure full cure without excessive heat buildup.

Drying Uniformity: Consistent and uniform UV output across the entire print width is crucial. Uneven curing can lead to patchy adhesion, poor print quality, and incomplete curing in certain areas. Look for systems designed with uniform LED arrays and advanced optics.

Cooling System: While LEDs generate less heat than mercury lamps, they still produce some. An effective cooling system is necessary to maintain optimal LED performance and longevity, and to prevent heat transfer to the substrate. Air cooling is common for many applications, but water cooling might be considered for very high-speed or high-power systems.

Integration with Press Equipment: The physical size and power requirements of the LED UV system must be compatible with the printing press. Ensuring proper ventilation and electrical connections is vital for safe and efficient operation.

Ink and Coating Formulation: The success of LED UV curing is also dependent on the formulation of the inks and coatings themselves. Manufacturers of UV-curable inks are continually developing new formulations specifically designed for LED curing, offering improved adhesion, flexibility, and cure speeds on a wide range of flexible packaging substrates.

Sustainability and Environmental Benefits

Beyond operational efficiencies, LED UV curing contributes to more sustainable printing practices. The significant energy savings reduce the carbon footprint of the printing operation. The absence of ozone production eliminates the need for exhaust ventilation systems, further reducing energy consumption and simplifying environmental compliance. The longer lifespan of LED lamps also means less waste generated from lamp replacements.

The environmental impact of packaging is a growing concern for consumers and brands. Adopting cleaner, more energy-efficient curing technologies like LED UV is a positive step towards more sustainable flexible packaging production.

The Future of Flexible Packaging Curing

LED UV curing technology continues to evolve. Innovations in LED chip design are leading to higher power outputs and more efficient energy conversion. Advancements in spectral control allow for even finer tuning of the UV output for specific ink chemistries.

For printers of flexible packaging, investing in LED UV curing systems is not just about adopting new technology; it’s about enhancing efficiency, improving print quality, reducing operational costs, and embracing a more sustainable future. The ability to achieve rapid, reliable curing on a diverse range of flexible materials makes LED UV an essential tool for any modern printing operation serving the dynamic flexible packaging market.