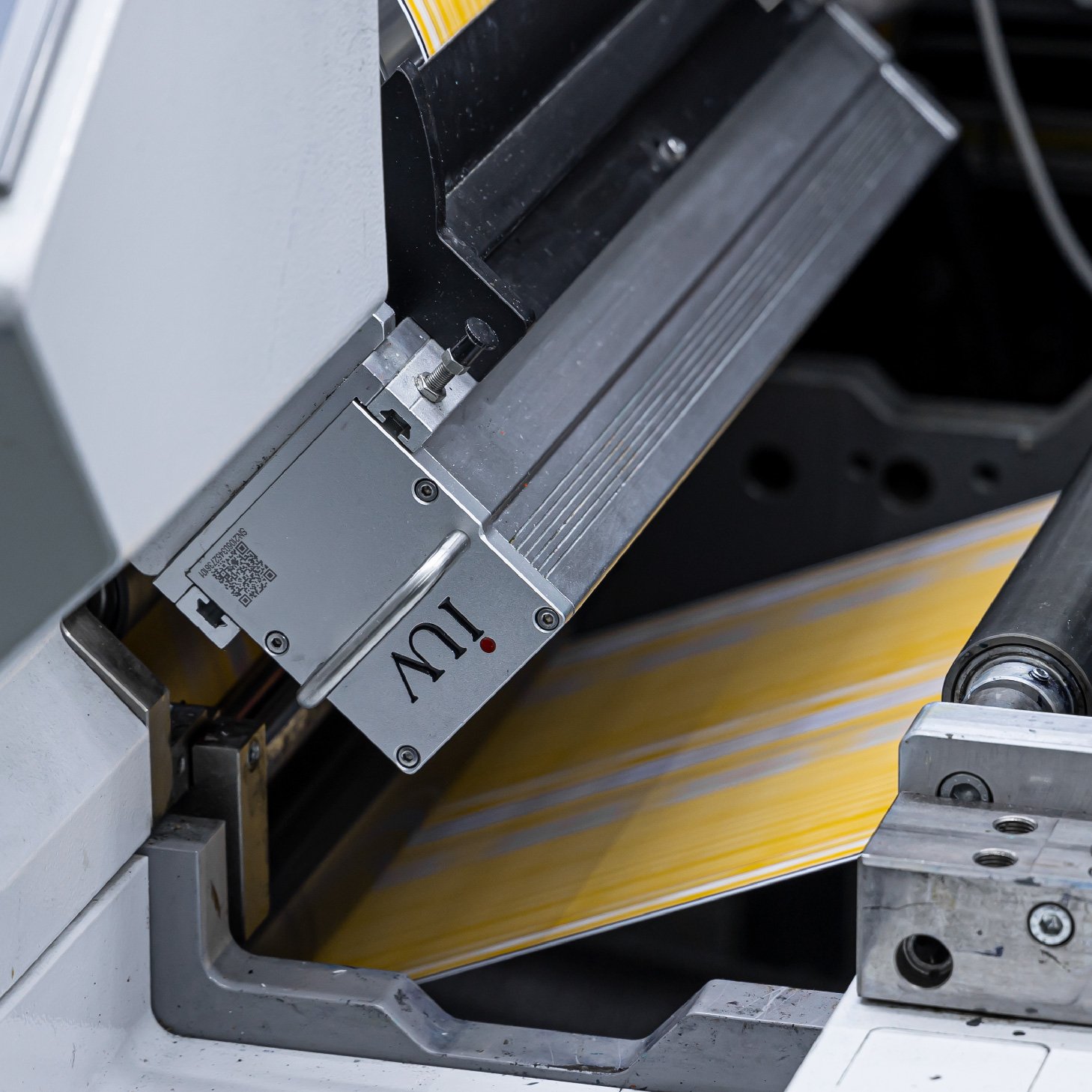

The Role of UV Curing Systems in Modern Offset and Flexographic Printing

In the rapidly evolving landscape of printing technology, UV curing systems have emerged as game-changers, particularly in offset, flexographic, and other narrow-width printing processes. Their ability to enable instant ink hardening significantly increases productivity, enhances print quality, and reduces environmental impact. This article explores how UV curing technology—especially LED UV systems—integrates with various printing methods to deliver superior results.

Understanding UV Curing Technology in Printing

UV curing involves using ultraviolet light to rapidly polymerize and dry inks, coatings, and adhesives. Traditional UV systems use mercury vapor lamps that produce broad-spectrum UV light, which cures inks almost instantly upon exposure. Recently, LED UV curing has gained traction due to its energy efficiency, longer lifespan, and ability to cure at lower temperatures, making it suitable for sensitive substrates.

This instantaneous curing process minimizes ink spread, allows for high-speed operation, and produces a more durable, glossy finish. When combined with specific inks formulated for UV technology, it enhances adhesion, color vibrancy, and chemical resistance.

Benefits for Tag Printing and Narrow-Band Applications

Tag printing often requires high precision and durability, especially when labels need to endure harsh conditions. UV curing ensures rapid processing, which is crucial for just-in-time production schedules. LED UV systems provide a flexible curing environment that can be precisely controlled, resulting in sharp images and vibrant colors with minimal delay.

In narrow-width printing, where space constraints demand compact and efficient equipment, LED UV systems fit seamlessly. They generate less heat, reducing warping or distortion in delicate substrates such as thin papers, plastics, or foils. Broadly, UV curing enhances throughput for tags and narrow-band jobs without sacrificing quality.

Flexographic and Lithographic Printing: How UV Curing Elevates Quality

Flexography, a dominant method for packaging and label production, benefits immensely from UV curing systems. Traditional solvent-based inks require lengthy drying times, which slow down the entire process. UV inks cure instantly upon UV exposure, enabling continuous, high-speed printing operations.

LED UV systems specifically match the speed and flexibility needed for narrow flexographic presses. The ability to control curing precisely on specific areas of a label or packaging component improves registration and sharpness. Moreover, LED UV’s low heat emission preserves the integrity of heat-sensitive substrates, expanding the scope of materials that can be used.

In lithographic offset printing, UV curing brings similar advantages. UV inks provide a high-gloss finish with excellent color depth. Instant curing prevents smudging during handling, reduces paper warping, and speeds up downstream processes such as packing or shipping. This technology is increasingly adopted in high-end applications demanding quality and efficiency.

Implementing LED UV Systems in Offset and Flexo Printing Lines

The transition to LED UV systems in offset and flexographic presses is straightforward, given their compact design and reduced energy requirements. These systems feature integrated cooling mechanisms, eliminating the need for external ventilation. Operators can start a job, switch between jobs, or change substrates with minimal downtime.

Furthermore, LED UV’s instant-on feature reduces power consumption and prolongs system lifespan. It allows for spot curing—where only specific areas of the substrate are cured—providing creative flexibility and resource savings. This precise control is especially beneficial for multi-layered and multi-application printing.

Environmental Impact and Sustainability Benefits

Shift towards UV curing, particularly LED-based systems, aligns with sustainable manufacturing goals. LED UV systems use no mercury, emit less heat, and consume significantly less energy compared to traditional UV lamps. The instant curing process minimizes waste, as less ink and substrate are discarded due to smudging or incomplete drying.

Additionally, UV inks have fewer volatile organic compounds (VOCs), reducing emissions and workplace hazards. These factors contribute to a greener production process, appealing to eco-conscious brands and consumers.

Future Trends: Innovation in UV Curing for Narrow-Width and Tag Printing

Advances continue in LED UV technology, with increasing power densities and spectral customization. These innovations favor higher-speed printing, better energy efficiency, and expanded material compatibility. For tag and narrow-width printers, this means greater flexibility to work with diverse substrates, including plastics, foils, and paper composites.

Smart integration with digital workflows enables dynamic curing parameters tailored to complex designs or variable data printing. This synergy accelerates the adoption of UV curing systems in small-batch, personalized, and short-run productions.

Practical Considerations for Selecting UV Curing Systems

When choosing a UV curing system, consider factors such as:

- Compatibility with substrates: Ensure the system can cure the materials used in your applications.

- Flexibility of curing options: Spot, flood, or selective curing capabilities enhance process control.

- Energy efficiency: LED systems typically deliver long-term savings.

- Ease of integration: Compatibility with existing presses and workflow management software.

- Maintenance and lifespan: Longer-lasting LEDs reduce downtime and operational costs.

Choosing the right system can dramatically improve productivity and print quality, aligning with the varying demands of modern printing environments.

Conclusion

UV curing systems, especially LED UV technology, have fundamentally transformed the process landscape across offset, flexographic, and narrow-width printing sectors. Their ability to deliver instant ink hardening streamlines production, improves quality, and supports sustainable practices. For tag, flexible, and narrow-width applications, adopting advanced UV curing solutions makes a tangible difference in meeting deadlines, elevating print finish, and expanding creative possibilities. As technology evolves, these systems will continue to push the boundaries of what’s feasible in high-speed, high-quality printing.