The world of printing is constantly evolving. Businesses demand faster turnaround times and higher quality. They want prints that look sharp and last. This is where modern curing technology truly shines. Specifically, LED curing systems are revolutionizing how we achieve instant ink curing and, consequently, smudge-free prints.

For years, traditional heat-curing methods were the standard. However, these methods have drawbacks. They require significant energy. They can also lead to substrate distortion, especially with heat-sensitive materials. Then there’s the extended drying time. This can slow down production lines considerably.

Enter UV curing technology. It uses ultraviolet light to instantly cure inks and coatings. This process is incredibly efficient. It offers superior print quality. But even traditional UV lamps have their limitations. They generate a lot of heat. Their lifespan is not as long. They also contain mercury, posing environmental concerns.

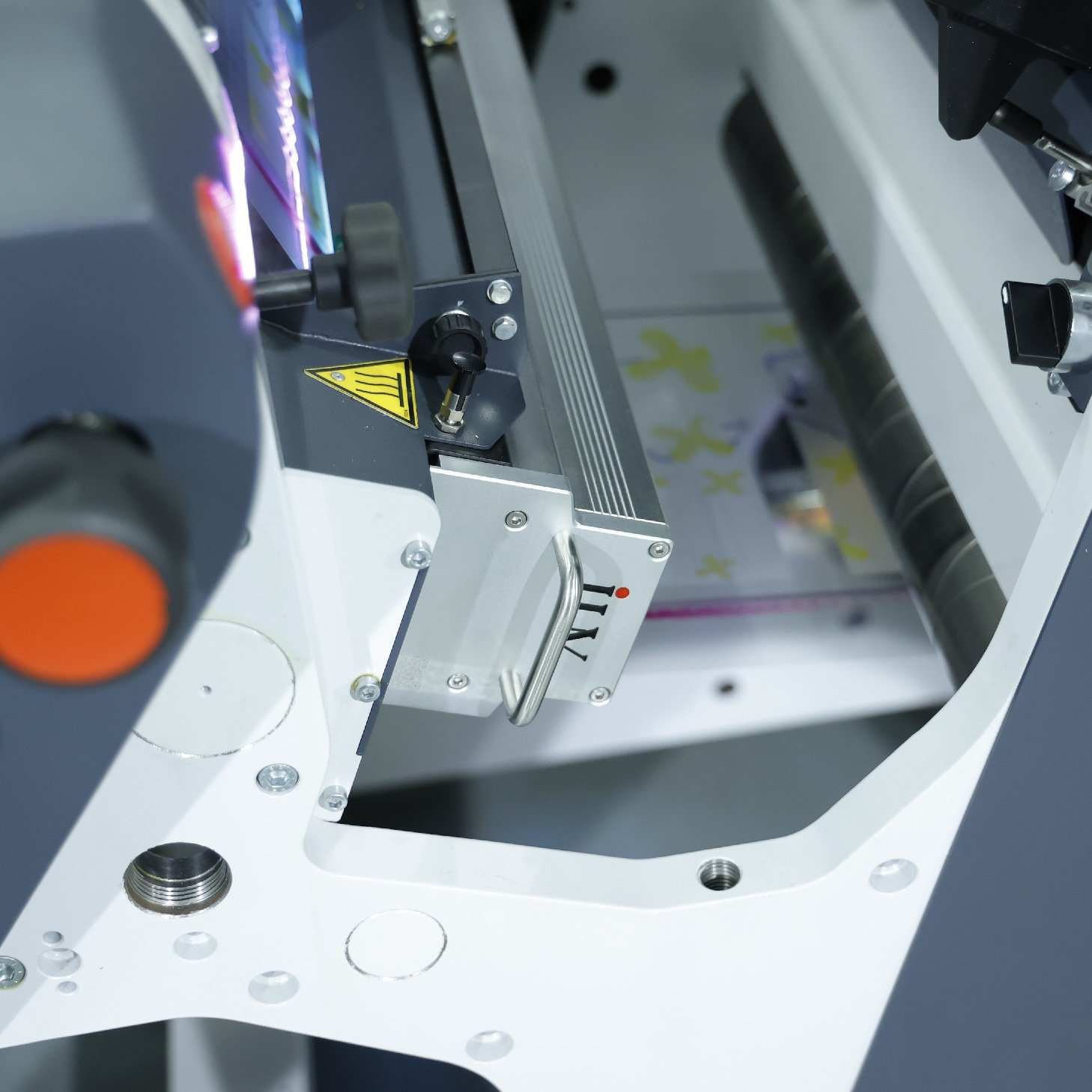

LED UV curing systems offer a significant leap forward. They use light-emitting diodes (LEDs) to produce UV light. This technology is a game-changer for many printing applications. Let’s explore why.

Instant Ink Curing: The Core Benefit

The primary advantage of LED curing is its ability to achieve instant ink curing. As soon as the UV light hits the ink, a photochemical reaction occurs. This reaction transforms the liquid ink into a solid, cured layer. There’s no waiting. The ink is dry, or rather, cured, immediately.

This instant cure is vital for several printing processes. In label printing, where intricate designs and vibrant colors are common, this speed is invaluable. Imagine labels needing immediate handling for cutting, folding, or packaging. Instant curing means no smudging. It ensures every detail remains crisp and clear. The labels are ready for the next step in seconds, not minutes.

Flexographic printing, often used for packaging and labels, also benefits immensely. Flexo presses run at very high speeds. Traditional drying methods can struggle to keep up. LED UV curing allows these presses to maintain their maximum speed. The ink cures instantly, preventing it from transferring to the anilox rolls or the next substrate layer. This leads to cleaner prints and reduced waste.

Offset printing, or lithographic printing, is another area where LED curing makes a difference. While traditionally associated with heat-set inks, UV-offset inks are becoming increasingly popular. LED curing allows for faster job throughput. It enables the printing of multiple colors on a single pass without ink transfer issues between stations. This is a significant efficiency gain for commercial printers.

Smudge-Free Prints: A Direct Result

The instant curing provided by LED systems directly leads to smudge-free prints. When ink is not fully cured, it remains vulnerable. Any contact can cause it to smear or smudge. This is a major quality concern. It can ruin an entire print run.

For narrow web printing, which focuses on labels and packaging produced on narrow-width presses, this is paramount. These applications often require handling shortly after printing. Smudge-free results are non-negotiable. LED curing ensures that the ink is permanently bonded to the substrate. This means the printed surface can be touched, stacked, or further processed immediately.

The implications for print quality are substantial. Sharp edges remain sharp. Fine text remains legible. Solid colors appear uniform and vibrant. There’s no need to worry about accidental smudges during post-press operations. This consistency builds client trust and reduces costly reprints.

The Technology Behind LED Curing

Unlike traditional mercury vapor lamps, LEDs emit light in a narrow, specific wavelength range. This targeted emission is more efficient. It means less wasted energy. It also means less heat is generated. This is a critical advantage for printing on delicate or heat-sensitive substrates like thin plastics, certain films, and even some papers.

The reduced heat output from LED systems is a boon for narrow web converters. They often work with a variety of materials where excessive heat can cause shrinkage or warping. LED curing allows for high-intensity UV output without damaging the substrate. This expands the range of materials that can be printed effectively and efficiently.

Furthermore, LED lamps have a significantly longer lifespan than traditional UV lamps. They can last for tens of thousands of hours. This reduces downtime for lamp replacement and lowers maintenance costs. They also switch on and off instantly, meaning no warm-up time is required. This further contributes to improved workflow efficiency.

Advantages Beyond Curing Speed

The benefits of LED UV curing extend beyond just instant ink curing and smudge-free results.

- Energy Efficiency: LEDs consume considerably less power than traditional UV lamps. This translates into lower operating costs and a smaller carbon footprint.

- Environmental Friendliness: LEDs do not contain mercury, making them a more environmentally responsible choice.

- Substrate Versatility: The lower heat output allows printing on a wider array of materials, including heat-sensitive plastics and films.

- Formulation Flexibility: LED curing encourages the development of new ink and coating formulations. These can be optimized for specific LED wavelengths, leading to even better performance and durability.

- Compact Design: LED systems are often more compact than traditional UV systems. This makes them easier to integrate into existing printing presses, especially in space-constrained flexographic and narrow web environments.

Conclusion

In the competitive landscape of label, flexographic, offset, and narrow web printing, efficiency and quality are paramount. LED UV curing systems provide a powerful solution. They deliver instant ink curing, ensuring smudge-free prints every time. This technology not only enhances print quality but also boosts production speed and reduces operational costs. As demand for faster, higher-quality, and more sustainable printing solutions grows, LED curing is setting a new standard for excellence. It’s a smart investment for any printer looking to stay ahead.