Achieving precise color and unwavering consistency in flexographic printing is a constant pursuit. For label printers, this goal directly impacts brand recognition and customer satisfaction. The advent of LED UV curing systems has significantly advanced our ability to meet these demands, offering a distinct advantage over traditional methods.

Flexo printing, especially in the narrow web sector for labels and packaging, relies on precise ink transfer. The quality of the final print hinges on several factors. Ink properties, anilox roll selection, plate stereotyping, and the curing process all play critical roles. Historically, mercury vapor lamps were the standard for UV curing. While effective, they presented challenges. Their heat output could affect ink viscosity and substrate stability. Furthermore, mercury lamps emitted a broad spectrum of UV light, leading to inconsistent curing depths and potential ink degradation.

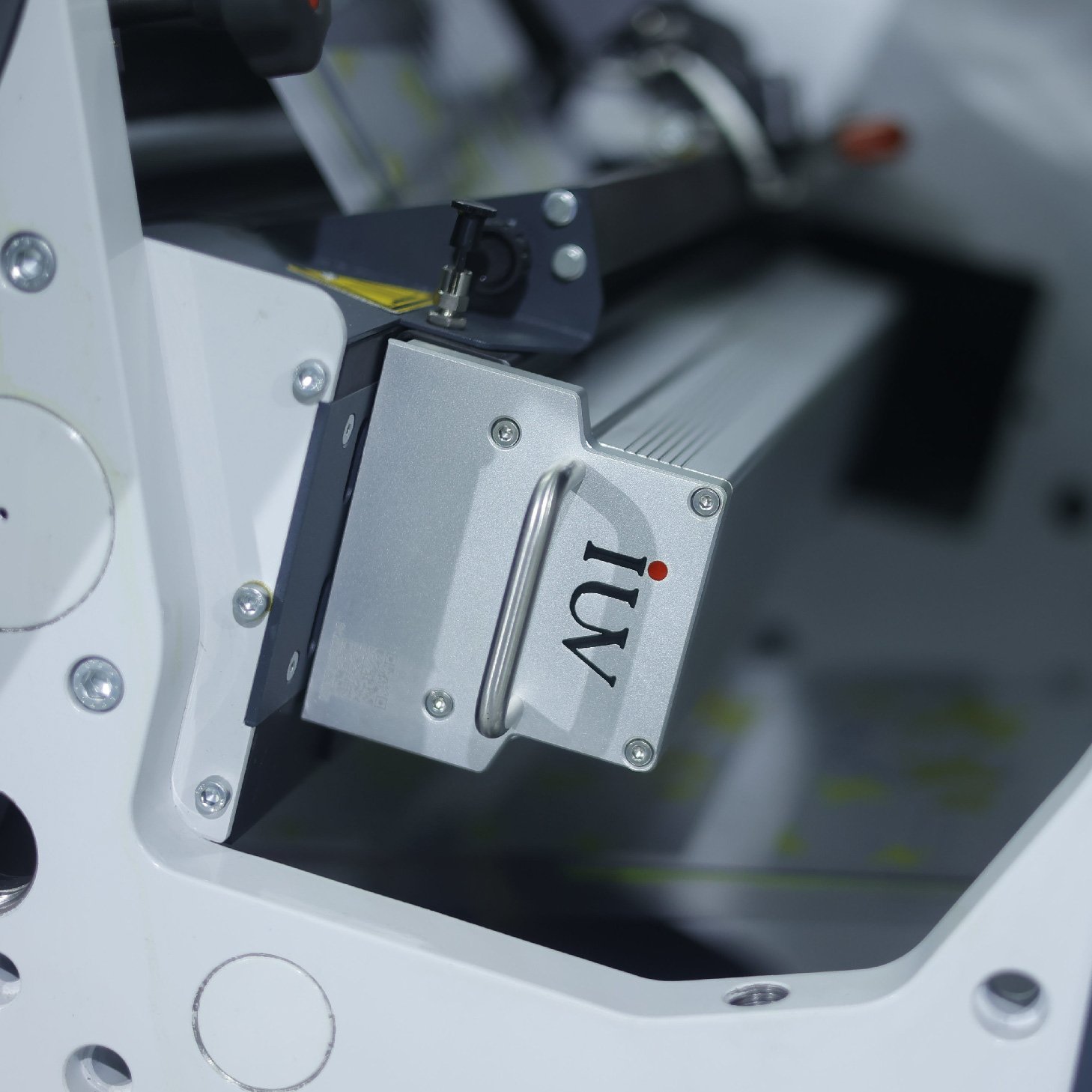

This is where LED UV curing systems truly shine. They utilize specific wavelengths of UV light, tailored to the photoinitiators within the inks. This targeted energy delivery ensures rapid and complete curing. Unlike mercury lamps, LED systems generate very little heat. This “cool curing” is a game-changer for sensitive substrates like thin films and heat-set papers. It prevents unwanted stretching or warping of the material, maintaining dimensional stability throughout the print run.

One of the most celebrated benefits of LED UV curing is its impact on color accuracy. Traditional mercury lamps can produce heat that causes inks to change properties during the printing process. This can lead to subtle shifts in color hue and saturation. LED curing, by contrast, provides a stable environment. The consistent energy output and minimal heat generation mean the ink cures uniformly without undergoing thermal distortion. This stability allows for the precise reproduction of brand colors, ensuring that every label printed perfectly matches the approved swatch.

Color consistency across long print runs is equally vital. Without it, a brand’s visual identity can be compromised. The on/off nature of mercury lamps, coupled with their aging characteristics, can lead to fluctuations in UV output over time. This necessitates frequent power adjustments and lamp replacements to maintain acceptable print quality. LED systems, however, offer a much more predictable and stable UV output. Their lifespan is significantly longer, and their performance remains consistent from the first impression to the last. This reliability translates directly into fewer make-ready times and reduced waste, as printers can trust that the color will stay true throughout the entire job.

Furthermore, the spectral output of LED lamps is precisely controlled. This means that the UV energy is delivered at the exact wavelengths required by the ink formulation. This efficient energy transfer leads to faster cure speeds, allowing for higher printing speeds without compromising ink adhesion or print quality. Faster curing also means that inks are fully cross-linked more quickly, preventing ink migration and ensuring excellent rub and scratch resistance. This is paramount for labels that endure handling and exposure.

The environmental advantages of LED UV curing are also noteworthy. Mercury lamps contain hazardous materials, requiring special disposal procedures. LED systems are mercury-free, making them a more environmentally responsible choice. Additionally, their energy efficiency is considerably higher. They consume less power than equivalent mercury lamp systems, leading to reduced electricity costs and a smaller carbon footprint. This aligns with the growing demand for sustainable printing practices within the packaging and label industry.

When considering color accuracy and consistency in flexo printing, the choice of curing technology is paramount. LED UV systems offer a superior solution by providing controlled, efficient, and stable UV energy. This translates into sharper prints, more vibrant colors, and an unparalleled level of consistency from start to finish. For label printers looking to elevate their quality, reduce waste, and embrace sustainable technology, the adoption of LED UV curing is a clear path forward. The ability to achieve exact color matches and maintain that perfection across thousands of labels is no longer an aspiration, but a tangible reality with modern LED curing technology. This precision empowers brands to present themselves flawlessly on the shelf, every single time.