How UV Curing Systems Reduce VOC Emissions in Printing

The printing industry has long faced challenges balancing high-quality output with environmental responsibility. Volatile Organic Compounds (VOCs), emitted by solvent-based inks and coatings, contribute to air pollution and workplace hazards. UV curing systems—particularly LED-based technologies—are revolutionizing print production by slashing VOC emissions while enhancing efficiency. Let’s explore how this innovation benefits label, flexographic, offset, and narrow-web printing.

The VOC Problem in Traditional Printing

Traditional printing methods rely on solvent-borne inks that release VOCs during drying. These chemicals evaporate into the atmosphere, posing health risks and environmental harm. In processes like flexographic or narrow-web printing, where fast drying is critical, solvent use becomes a necessary evil. Even offset printing, known for its precision, struggles with VOC-heavy fountain solutions and cleaning agents.

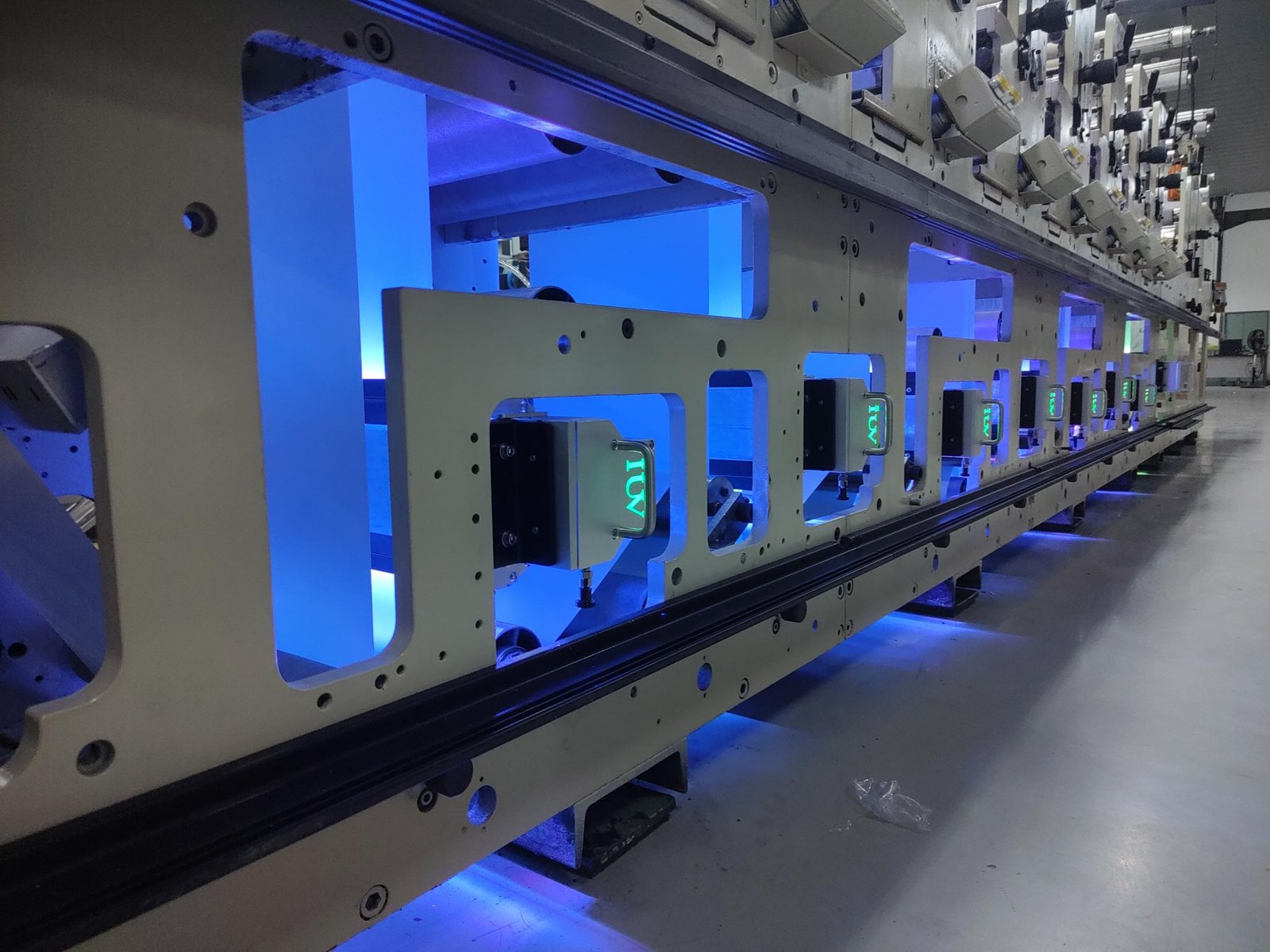

UV curing eliminates solvents by using 100% solid inks or coatings activated by ultraviolet light. No evaporation occurs, cutting VOC emissions to near-zero levels. This shift aligns with global regulations like REACH and EPA standards, helping printers meet sustainability goals without sacrificing performance.