Key Factors to Consider When Buying a UV Curing System for Printing Applications

Selecting the right UV curing system is critical for optimizing print quality, production speed, and operational costs in label, flexo, offset, and narrow-web printing. LED UV technology has revolutionized curing processes, but choosing equipment requires careful evaluation of technical and operational needs. Below are seven essential factors to guide your decision.

1. Wavelength Compatibility with Inks/Substrates

UV curing relies on precise light wavelengths to initiate photopolymerization in inks or coatings. LED UV systems typically emit 365-405 nm wavelengths, but specific formulations (e.g., white inks, specialty coatings) may require tailored spectra. For label printing, ensure compatibility with fast-curing, low-migration inks. In offset or flexo printing, verify the system handles thicker ink layers without under-curing. Always test equipment with your substrates to avoid adhesion failures or yellowing.

2. Curing Speed vs. Production Demands

Curing speed directly impacts throughput. High-speed narrow-web presses (200 meters/minute) demand systems with instant-on/off capabilities and uniform irradiance across the web. For sheetfed offset or hybrid setups, prioritize adjustable intensity to balance speed and cure depth. Avoid over-specifying: excessive power increases costs without improving results.

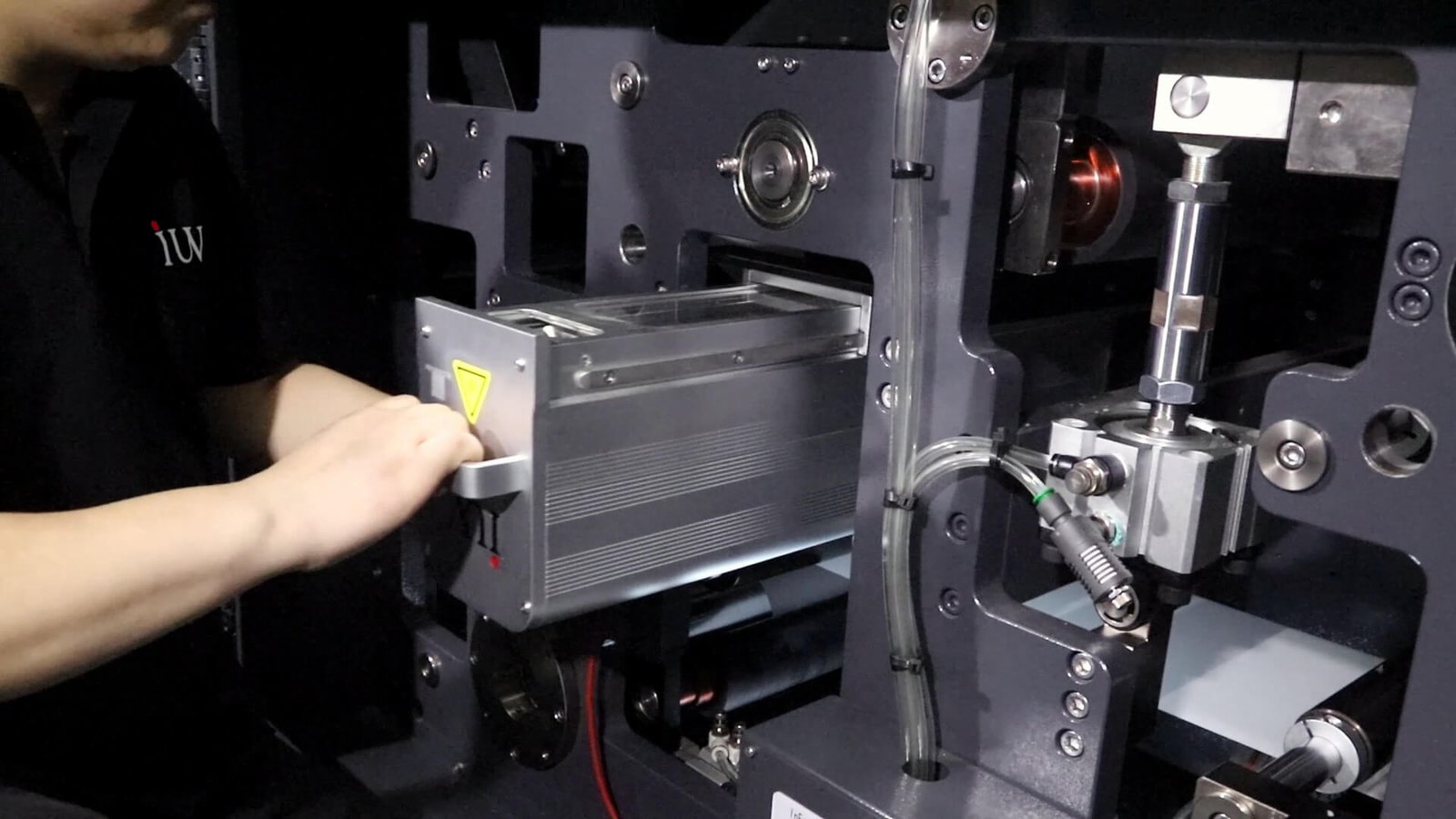

3. Cooling System Efficiency

LED UV systems generate heat, which can distort thin films or heat-sensitive substrates like PET labels. Integrated air or water cooling maintains optimal operating temperatures (typically below 40°C). In flexo printing, where dies and plates are heat-sensitive, robust cooling prevents downtime and material waste.