For narrow web flexo label printers, upgrading to LED UV curing is no longer just a technology trend but a strategic production decision. The performance of an LED UV system directly influences curing reliability, color stability, press speed, and substrate compatibility. Choosing the wrong configuration can limit ink cure, reduce adhesion, or create bottlenecks that negate the expected efficiency gains. Because every flexo press has its own mechanical layout, speed range, and application focus, system selection must be based on process requirements rather than nominal power ratings alone. A structured evaluation approach helps ensure that the LED UV system integrates smoothly with existing equipment and supports long-term production goals.

Understanding Your Current Flexo Press Configuration

The first step in selecting an LED UV system is a detailed assessment of the existing press. Narrow web flexo presses vary significantly in terms of station spacing, available mounting locations, web width, and maximum line speed. These parameters determine where LED modules can be installed and how much curing energy is required at each position. Presses running high-resolution labels with multiple color decks often benefit from interstation pinning, while presses focused on heavy whites or varnishes may require higher output at the final curing position. Understanding the mechanical constraints of the press ensures that the chosen LED system delivers uniform irradiance across the web without interfering with press operation or maintenance access.

Matching LED Wavelength to Ink Chemistry

Ink compatibility is one of the most critical factors in LED UV system selection. LED UV curing relies on specific wavelengths, typically centered around 365, 385, or 395 nanometers, to activate the photo-initiators within the ink formulation. Existing inks designed for mercury arc systems may not respond efficiently to narrow-band LED output. Before finalizing system specifications, printers must confirm that their inks, coatings, and varnishes are formulated for LED curing or can be easily transitioned. Selecting the appropriate wavelength ensures rapid polymerization, strong interlayer adhesion, and consistent surface properties across different substrates.

Determining Required Irradiance and Dose

In flexo label printing, curing performance depends on both peak irradiance and total energy dose delivered to the ink film. High-speed presses with dense ink coverage require sufficient irradiance to initiate cure instantly, while adequate dose ensures full through-cure and long-term adhesion. When evaluating LED UV systems, it is important to consider realistic production speeds rather than theoretical maximums. Systems should be capable of delivering stable output at the highest intended line speed without operating at the edge of their performance range. This margin improves consistency, extends component life, and provides flexibility for future process upgrades.

Evaluating Optics and Beam Uniformity

Optical design plays a major role in curing efficiency on narrow web presses. LED UV systems use lenses or reflectors to shape and distribute light across the web width. Poor beam uniformity can lead to undercured edges, uneven gloss, or color variation across the label. When selecting a system, attention should be given to lens efficiency, beam overlap, and edge-to-edge uniformity. Well-designed optics ensure consistent curing on both narrow and full-width jobs, reducing waste and improving repeatability. This is especially important for presses producing variable-width labels or running frequent job changes.

Considering Thermal Management and Substrate Sensitivity

One of the key advantages of LED UV curing is reduced heat generation, but thermal management remains an important selection criterion. High-output LED arrays still produce localized heat that must be managed to protect sensitive substrates and maintain module performance. Systems with effective air or liquid cooling maintain stable output and prevent thermal drift during long production runs. For label printers working with thin films, metallized substrates, or heat-sensitive adhesives, selecting a system with controlled thermal characteristics helps preserve web stability and adhesive performance.

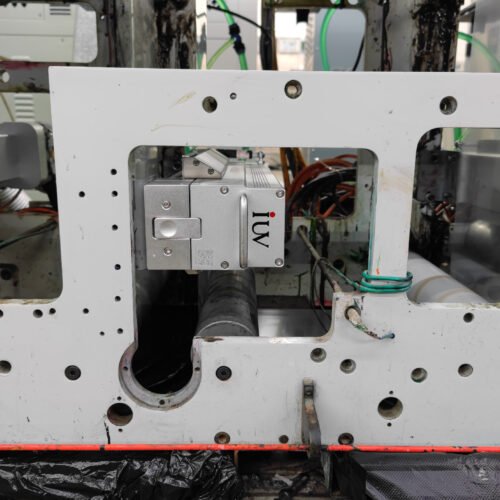

Integration with Press Controls and Workflow

Modern LED UV systems are designed to integrate with existing press controls, allowing synchronized operation with press speed and job settings. Seamless integration enables automatic power adjustment, instant on and off functionality, and real-time monitoring of curing parameters. When choosing a system, it is important to evaluate how the LED controller interfaces with the press PLC or operator console. Intuitive control integration reduces operator training time and minimizes the risk of setup errors during job changes. This level of integration supports efficient short-run production and consistent curing across multiple shifts.

Maintenance, Reliability, and Service Considerations

Long-term reliability is a decisive factor in LED UV system selection. Unlike mercury lamps, LED modules are solid-state devices with extended service life, but performance depends on component quality and system design. Printers should consider module lifespan, cooling system robustness, and ease of maintenance access. A well-designed system minimizes downtime and ensures consistent output over thousands of operating hours. Access to technical support and replacement parts is also essential, particularly for presses operating in multi-shift environments where uptime directly affects profitability.

Aligning System Choice with Production Strategy

Choosing the right LED UV system is not only a technical decision but also a strategic one. Printers focused on premium labels, high-resolution graphics, or specialty substrates may prioritize curing precision and beam uniformity. Operations emphasizing high throughput and cost efficiency may focus on energy savings, minimal maintenance, and rapid setup. Aligning system capabilities with production priorities ensures that the investment delivers measurable returns in productivity, quality, and operating cost reduction.

Preparing for Future Process Expansion

An effective LED UV system should support future process changes, including new ink sets, coatings, or press speed upgrades. Selecting a modular system with scalable output allows printers to adapt without replacing the entire curing solution. This flexibility is particularly valuable in narrow web environments where customer demands and substrate trends evolve rapidly. A future-ready system protects the investment and supports long-term competitiveness.

Conclusion

Selecting the right LED UV system for existing flexo equipment requires a structured evaluation of press configuration, ink chemistry, curing requirements, and operational goals. By focusing on wavelength compatibility, irradiance capability, optical uniformity, and system integration, label printers can ensure reliable curing performance across a wide range of applications. When properly matched to the press and production strategy, an LED UV system enhances print quality, increases press efficiency, and reduces operational costs. For narrow web flexo converters, this step-by-step approach provides a clear path to a successful and sustainable transition to LED UV curing.