For many label printers, the move from traditional UV curing to LED UV technology is no longer a question of if, but when. Narrow web operations face increasing pressure to improve efficiency, reduce waste, and maintain consistent print quality across a wider range of substrates. At the same time, energy consumption, maintenance demands, and regulatory considerations are forcing converters to re-evaluate legacy UV systems that were once considered standard.

Switching to LED UV curing represents a fundamental process change rather than a simple hardware replacement. Understanding how curing behavior, ink chemistry, press dynamics, and operator interaction change is essential for a successful transition.

Why Traditional UV Systems Are Being Reconsidered

Conventional mercury arc UV lamps emit a broad ultraviolet spectrum and rely on thermal radiation as part of the curing process. While effective, these systems introduce heat into the web, require warm-up and cooldown cycles, and suffer gradual output degradation as bulbs age. In narrow web label printing, this heat can affect thin films, pressure-sensitive adhesives, and dimensional stability, particularly at higher press speeds.

LED UV systems operate on a different principle. They emit a narrow, controlled wavelength band with instant on and off capability. The absence of infrared radiation significantly reduces heat transfer to the substrate. This difference alone changes how inks cure, how substrates behave, and how presses can be operated during setup and production.

Assessing Press Compatibility Before Conversion

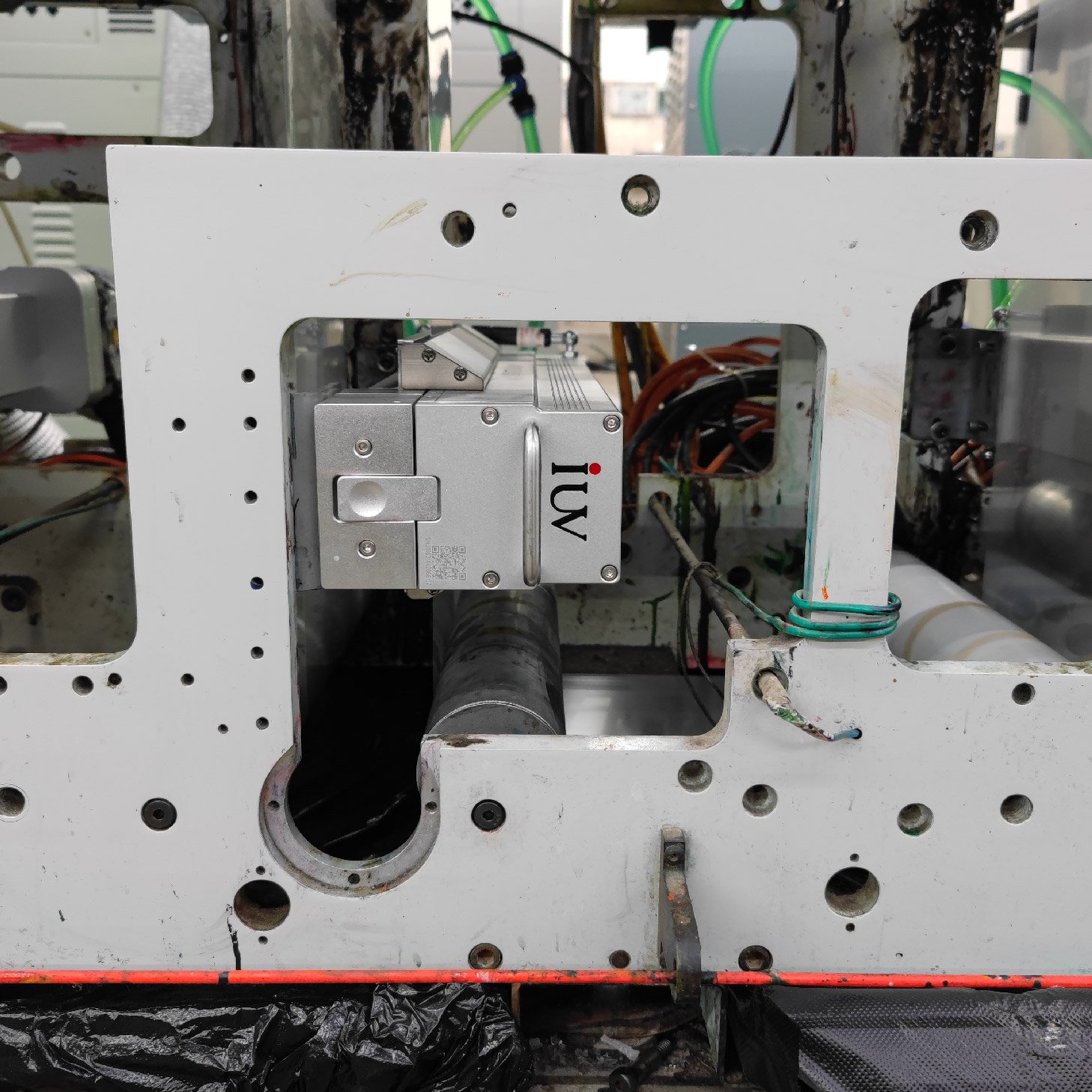

Most modern narrow web rotary presses are mechanically compatible with LED UV curing units, but compatibility should never be assumed. Station spacing, web path geometry, and available mounting locations influence how effectively LED modules can be installed. Because LED UV systems deliver highly directional energy, placement accuracy becomes more critical than with traditional flood-style UV lamps.

Older presses may require custom brackets or minor frame modifications to maintain consistent curing distance across the web. A detailed evaluation of the press layout helps prevent uneven irradiance, shadowing, or accessibility issues during maintenance.

Ink Behavior Changes Under LED UV Curing

One of the most common mistakes during an LED UV transition is underestimating the role of ink chemistry. Traditional UV inks are formulated to respond to broad-spectrum output and higher radiant heat. LED UV inks rely on specific photoinitiators optimized for narrow wavelength ranges and lower thermal input.

When switching curing technology, ink performance must be revalidated. Adhesion, surface cure, and interlayer bonding behave differently under LED UV exposure. In flexographic label printing, this often results in sharper dot reproduction and improved edge definition, but only when ink formulations are properly matched to the LED output.

Selecting the Right LED UV Wavelength Strategy

Not all LED UV systems are the same. Wavelength selection directly affects curing depth, surface hardness, and ink reactivity. In narrow web label applications, the correct wavelength depends on ink formulation, coating thickness, and press speed requirements.

Some printers benefit from hybrid wavelength strategies that balance surface cure with through-cure performance. Choosing the correct configuration ensures consistent curing without excessive exposure, which can lead to brittleness or adhesion issues.

Installation Considerations That Affect Long-Term Performance

Although LED UV units are smaller and lighter than mercury lamps, installation quality has a lasting impact on curing consistency. Maintaining a stable distance between the LED module and the substrate ensures uniform irradiance across the web width. Even small deviations can lead to undercured edges or excessive exposure in the center.

Cooling performance also plays a role. While LED systems generate less radiant heat, effective thermal management is required to maintain output stability over long production runs. Proper airflow or liquid cooling integration prevents output drift and protects diode lifespan.

Electrical Integration and Press Control Synchronization

Traditional UV systems rely on shutters and constant output levels. LED UV curing introduces digital control, allowing output to be adjusted dynamically with press speed. This capability improves efficiency but requires proper integration with the press control system.

Synchronization between curing output and press speed ensures consistent UV dose delivery during acceleration, deceleration, and job changeovers. Safety interlocks, emergency stop circuits, and fault monitoring must be fully integrated to maintain compliance and operator protection.

Process Adjustment After Switching to LED UV

Once installed, LED UV curing requires a recalibration of process parameters. Ink film thickness, anilox selection, and press speed interact differently under LED exposure. Printers often discover that lower ink laydown still achieves full cure, reducing material consumption.

Radiometric measurement becomes an essential tool during this phase. Measuring delivered UV dose at production speeds allows printers to validate curing performance rather than relying on visual inspection alone. Controlled adjustments help achieve stable curing without sacrificing throughput.

Substrate Stability and Print Quality Improvements

One of the most immediate benefits observed after switching to LED UV is improved substrate stability. Reduced heat input minimizes web stretching, shrinkage, and distortion, particularly on thin films and unsupported stocks. This stability improves register control and color consistency across long runs.

In high-resolution flexo label printing, improved dot integrity and reduced gain are common outcomes. These improvements translate into sharper graphics and more predictable color reproduction, especially in multi-color work.

Operator Adaptation and Workflow Changes

LED UV curing changes daily press operation. There is no warm-up period, and output responds instantly to control adjustments. While this improves responsiveness, it also requires operators to develop a more precise understanding of curing behavior.

Training focuses on recognizing curing margins, adjusting output efficiently, and understanding how LED UV interacts with ink and substrate variables. Well-trained operators are key to maintaining consistent quality across shifts.

Maintenance Expectations and Reliability

Compared to mercury arc systems, LED UV curing significantly reduces routine maintenance. There are no bulbs to replace, no reflectors to degrade, and no shutters to service. Maintenance primarily involves keeping optical surfaces clean and ensuring cooling systems operate correctly.

Stable output over time improves repeatability and reduces the need for frequent recalibration. This reliability supports higher press uptime and more predictable production planning.

Evaluating the Business Impact of Conversion

Beyond technical benefits, LED UV curing delivers measurable operational advantages. Energy consumption is reduced, cooling requirements are lower, and consumable costs decrease. Faster setups and reduced startup waste improve overall equipment efficiency.

For label printers operating in competitive markets, these gains support shorter lead times and more flexible production schedules. Environmental benefits further strengthen customer and regulatory alignment.

Final Perspective for First-Time LED UV Users

Switching from traditional UV to LED UV curing is a strategic upgrade for narrow web label printers. When approached with a clear understanding of press mechanics, ink behavior, and process control, the transition delivers long-term technical and economic advantages.LED UV curing supports higher consistency, lower waste, and greater process stability, making it a logical next step for printers modernizing their operations.