Metalized narrow web films remain one of the most challenging substrates in label printing. Despite advances in LED UV curing, converters still encounter ink adhesion failures, edge pick-off, flaking after die cutting, and delamination during application. These problems rarely originate from curing power alone. In most cases, they result from an imbalance between surface tension, ink wetting behavior, and polymerization dynamics under LED UV exposure. Understanding this interaction is essential for stable production in flexographic and offset narrow web label printing.

Characteristics of Metalized Narrow Web Substrates

Metalized films typically consist of a polymer base such as PET or BOPP with a vacuum-deposited aluminum layer. This structure creates a smooth, low-porosity surface with limited surface energy. Compared to paper or coated films, metalized substrates offer minimal mechanical anchoring for ink films. Adhesion therefore relies almost entirely on surface wetting and chemical bonding. Any disruption in surface energy uniformity leads to rapid ink rejection and adhesion loss.

Surface Tension Fundamentals in Label Printing

Surface tension governs how well an ink spreads across a substrate. For reliable adhesion, the surface energy of the metalized film must exceed the surface tension of the ink by a safe margin. In narrow web printing, this margin typically ranges between 8 and 12 dynes. When the gap is smaller, ink beads, retracts, or forms micro-voids that compromise adhesion. LED UV curing locks in these defects if wetting is incomplete at the moment of polymerization.

Ink Wetting Behavior Under LED UV Conditions

LED UV curing introduces unique wetting challenges. Unlike mercury UV lamps, LED systems emit narrow-band radiation with lower radiant heat. This reduces ink viscosity drop during printing. On metalized films, higher viscosity slows wetting and increases sensitivity to surface energy variations. If the ink does not fully level before exposure, partial curing fixes poor contact with the substrate. This often appears as acceptable adhesion immediately after printing but fails during downstream processes.

Common Adhesion Failure Modes on Metalized Films

Adhesion failure presents in several recognizable forms. Ink may crack or flake after die cutting, indicating poor anchorage. Tape tests may show clean ink removal, revealing inadequate wetting. In other cases, adhesion appears acceptable until labels are applied to curved containers, where flex stress causes ink lift. These symptoms point to surface tension imbalance rather than insufficient UV dose alone.

Evaluating Surface Energy on Press

Accurate surface energy measurement is the foundation of troubleshooting. Dyne pens or test fluids should be applied inline before printing. Metalized films often show uneven surface energy across the web due to coating variability or handling contamination. Values below 38 dynes are high risk for LED UV flexo inks. Even when corona treated, metalized films can lose surface energy rapidly if stored improperly.

The Role of Corona and Plasma Treatment

Surface treatment is essential for improving ink wetting on metalized films. Corona treatment increases surface energy by oxidizing the polymer layer beneath the metal coating. Plasma treatment provides more controlled activation and longer-lasting effects. However, excessive treatment can damage the metal layer, reducing adhesion rather than improving it. Treatment levels must be optimized specifically for LED UV ink systems and validated during production trials.

Ink Formulation Considerations for Metalized Films

Not all LED UV inks behave equally on metalized substrates. Pigment loading, oligomer selection, and photoinitiator type influence wetting and cure depth. Inks designed for paper or standard films often show poor flow on metalized surfaces. Low surface tension ink formulations improve wetting but may increase dot gain. Balancing wetting and print sharpness is critical in high-resolution narrow web applications.

Anilox Selection and Ink Film Thickness

Ink film thickness strongly affects wetting behavior. Excessive ink volume can trap air at the interface, especially on smooth metalized films. Fine anilox volumes often improve adhesion by allowing faster wetting and more uniform contact. In LED UV flexo printing, thinner films also cure more efficiently, reducing the risk of undercured interfaces that lead to adhesion loss.

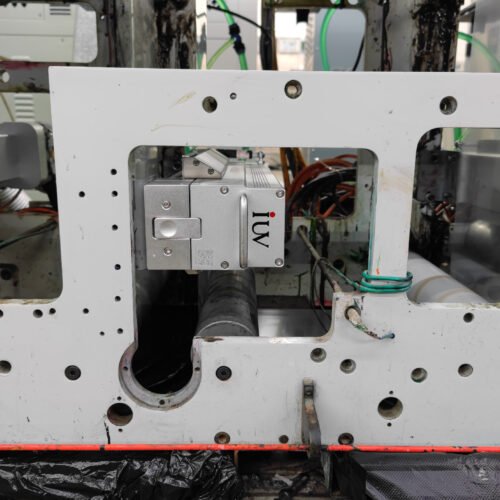

LED UV Irradiance Timing and Pinning Strategy

Curing strategy plays a decisive role in adhesion outcomes. Immediate high-intensity exposure can freeze ink before proper wetting occurs. Controlled pinning using lower irradiance allows ink to spread and level before final cure. On metalized films, delayed full cure improves interfacial bonding and reduces internal stress within the ink layer. This approach is especially important in multi-color narrow web presses.

Wavelength Selection and Polymerization Depth

LED UV wavelength influences how energy penetrates pigmented inks. Longer wavelengths such as 395 nm penetrate deeper but may polymerize more slowly at the surface. Shorter wavelengths promote faster surface cure but can limit depth of cure. On metalized films, insufficient depth of cure at the ink-substrate interface weakens adhesion. Matching wavelength to ink chemistry ensures balanced polymerization through the ink layer.

Temperature Effects on Wetting and Cure

Although LED UV generates minimal radiant heat, substrate temperature still affects ink flow. Cold metalized films reduce wetting speed and increase viscosity. Slight preheating of the web or maintaining stable pressroom temperature can significantly improve adhesion consistency. Temperature control is often overlooked during troubleshooting but plays a measurable role in wetting behavior.

Press Speed and Dwell Time Considerations

Higher press speeds reduce the time available for ink wetting before curing. On metalized films, this effect is amplified due to low surface energy. If press speed increases without adjusting curing delay or pinning strategy, adhesion failures often follow. Balancing speed, dwell time, and irradiance is essential for stable production.

Diagnostic Testing for Adhesion Root Causes

Systematic testing helps isolate the root cause of adhesion failure. Tape tests, cross-hatch adhesion tests, and post-cure rub resistance evaluations provide valuable data. Comparing results before and after surface treatment adjustments or curing changes reveals whether the issue is wetting-related or cure-related. Reliable diagnostics prevent unnecessary increases in UV power that do not address the real problem.

Long-Term Process Stability on Metalized Films

Achieving consistent adhesion on metalized narrow web films requires process discipline. Surface treatment levels must be monitored regularly. Ink batches should be controlled for viscosity and surface tension. LED UV output must remain stable across shifts. When these variables are controlled together, adhesion failures become predictable and manageable rather than recurring surprises.

Conclusion: Building Adhesion Reliability with LED UV on Metalized Films

Adhesion failure on metalized narrow web films is rarely caused by a single factor. It is the result of interactions between surface tension, ink wetting, curing timing, and substrate condition. LED UV curing offers precise control, but only when integrated with a deep understanding of surface science and press dynamics. By addressing wetting behavior before polymerization and aligning curing strategy with material properties, converters can achieve reliable adhesion and consistent performance in demanding label applications.