The relentless pace of modern commerce demands ever-increasing efficiency in production, and the label printing industry is no exception. For businesses focused on high-volume, narrow-web label runs, achieving both speed and exceptional quality has become a critical competitive advantage. This is where the synergy of narrow-web flexographic printing and advanced LED UV curing technology truly shines, offering a potent solution for optimizing throughput and elevating finished product standards.

Traditionally, flexographic printing has been a workhorse for label production, known for its versatility and ability to handle a wide range of substrates. However, enhancing the speed of these presses, particularly in the narrow-web segment (typically under 20 inches wide), presented challenges. Traditional UV curing systems, often employing mercury vapor lamps, could limit press speeds due to their heat output, energy consumption, and the need for longer curing times. These limitations directly impacted overall production efficiency and the potential for higher output.

The Rise of LED UV Curing in Flexography

The introduction of Light Emitting Diode (LED) UV curing technology has been a game-changer for the flexographic printing world. Unlike mercury lamps, LEDs emit UV light at specific wavelengths, precisely tailored to initiate the polymerization of UV-curable inks and coatings. This targeted emission results in faster, more efficient curing, even at higher press speeds.

In the context of narrow-web flexo, LED UV offers several distinct advantages that directly address the demands of high-speed production.

Faster Curing, Faster Presses

One of the most significant benefits of LED UV curing is its remarkable speed. The precise wavelengths emitted by LEDs lead to rapid photoinitiator activation within the ink. This allows for near-instantaneous curing as the substrate passes under the lamps. For narrow-web presses operating at high linear speeds, this means that the ink and coatings are fully cured and ready for the next printing station or finishing process without any delay. This eliminates bottlenecks that were common with older UV technologies, enabling presses to run at their maximum mechanical capabilities. The result is a tangible increase in the number of labels produced per hour.

Reduced Heat, Improved Substrate Versatility

A notable characteristic of LED UV lamps is their significantly lower heat output compared to traditional mercury lamps. This is crucial for narrow-web printing, which frequently utilizes heat-sensitive substrates like thin films, some papers, and specialized plastics. Excessive heat can cause these materials to warp, shrink, or even degrade, leading to print defects and material waste. LED curing minimizes this heat transfer, allowing printers to confidently run a broader array of substrates at high speeds without compromising material integrity. This expanded substrate capability opens up new market opportunities and allows for greater flexibility in product offerings.

Energy Efficiency and Environmental Benefits

Beyond speed and substrate handling, LED UV technology presents compelling economic and environmental advantages. LEDs are considerably more energy-efficient than mercury vapor lamps, consuming up to 70% less power. This translates into substantial operational cost savings, particularly for high-volume printing operations. Furthermore, LEDs have a much longer lifespan, reducing maintenance downtime and the frequency of lamp replacements. Environmentally, LEDs do not contain mercury, making disposal safer and more compliant with regulations. The reduced energy consumption also contributes to a smaller carbon footprint, aligning with the growing demand for sustainable manufacturing practices.

Optimizing Narrow-Web Flexo with LED Technology

Integrating LED UV curing into a narrow-web flexo press is more than just a component upgrade; it’s a strategic enhancement that redefines production capabilities.

Enhanced Print Quality and Durability

The efficient and consistent curing provided by LED UV technology leads to superior print quality. Ink and coatings are fully cross-linked, resulting in excellent adhesion, rub resistance, and chemical resistance. This is vital for labels that endure demanding conditions, such as those found in food and beverage, pharmaceutical, or industrial product packaging. For high-speed production, maintaining consistent quality across thousands or millions of labels is paramount, and LED UV helps achieve this with reliability. The sharp dot definition and vibrant color reproduction are preserved, contributing to a premium finished product.

Reduced Setup Times and Waste

The rapid curing of LED UV inks means that presses can often be stopped and started more quickly without ink smearing issues. This can contribute to reduced setup times between jobs, as less time is spent waiting for inks to dry or dealing with post-print handling. While not directly related to curing speed, the overall efficiency gains from faster presses and fewer curing-related issues can indirectly lead to less material waste during setup and short runs.

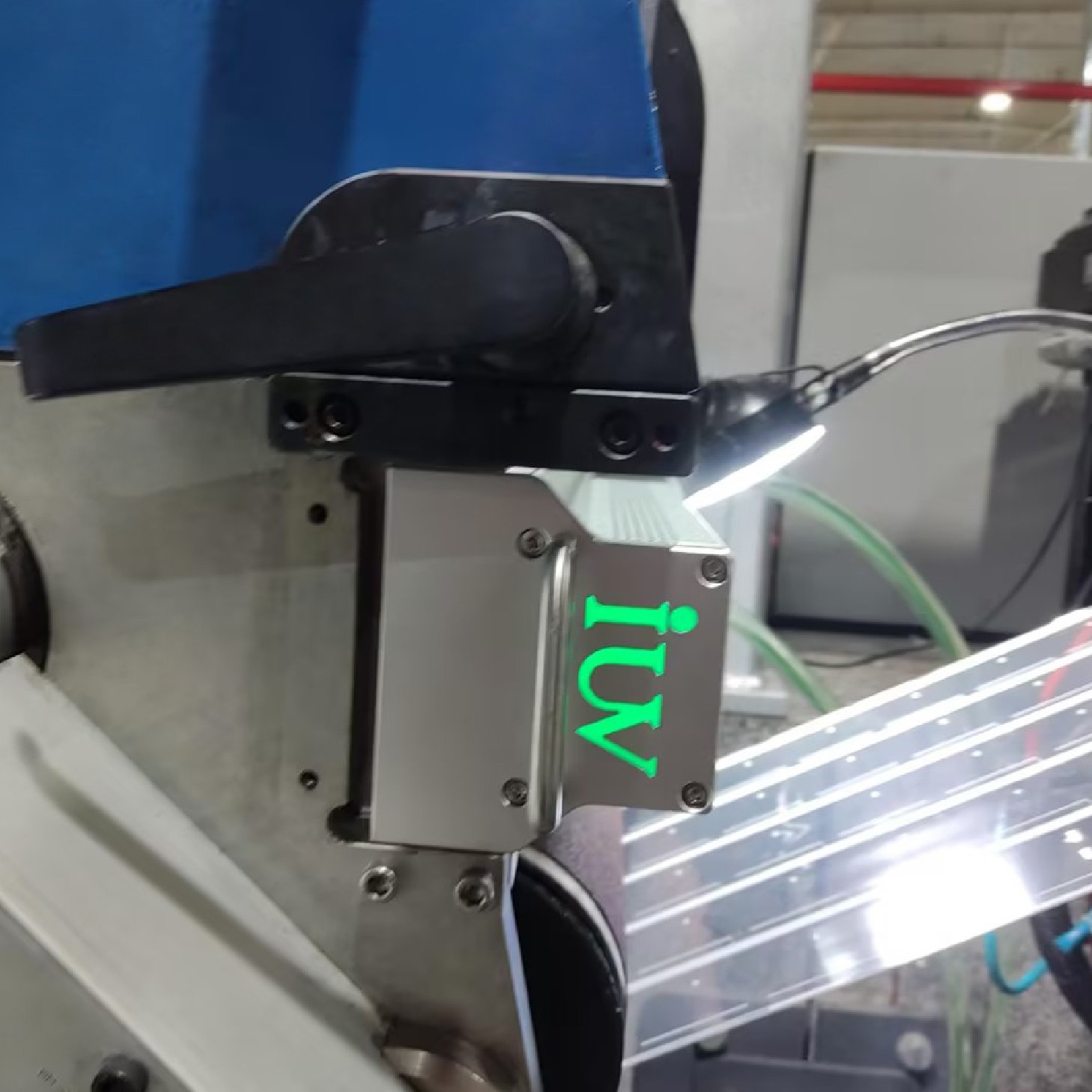

Integration with Modern Press Designs

Modern narrow-web flexo presses are increasingly designed with LED UV curing in mind. This integration ensures optimal placement of the LED units, efficient ventilation, and seamless communication between the press controls and the curing system. This holistic approach maximizes the performance benefits of both the press and the curing technology. The modular nature of LED curing systems also allows for easier retrofitting onto existing presses, providing a pathway for printers to upgrade their capabilities without investing in entirely new machinery.

Challenges and Considerations

While the advantages are clear, implementing LED UV curing in a narrow-web flexo environment does come with considerations.

Ink and Coating Formulations

Not all traditional UV inks are optimized for LED curing. Printers need to ensure they are using ink and coating formulations specifically designed for LED wavelengths. These formulations contain specific photoinitiators that respond effectively to the LED spectrum. Working closely with ink manufacturers is key to selecting the right products for optimal performance.

Initial Investment

The initial cost of LED UV curing systems can be higher than traditional mercury lamp systems. However, this upfront investment is often offset by the long-term savings in energy consumption, reduced maintenance, and increased production output. A thorough cost-benefit analysis is recommended to evaluate the return on investment for specific operations.

Spectrum and Wavelength Management

Different LED UV lamps emit light within specific wavelength ranges (e.g., 395nm, 405nm). It’s important to match the ink formulation to the correct LED wavelength for efficient curing. Understanding these specifications and working with knowledgeable suppliers ensures that the curing system is correctly configured for the chosen inks and substrates.

The Future is Fast and Efficient

The combination of narrow-web flexographic printing and LED UV curing technology represents a significant leap forward in label production. By enabling higher press speeds, accommodating a wider range of substrates, improving print quality, and offering substantial energy savings, this technology empowers label converters to meet the demanding needs of today’s market. As the industry continues to prioritize efficiency, sustainability, and quality, the adoption of narrow-web LED flexo printing is poised to become an even more integral part of successful label manufacturing operations. The ability to produce more labels, faster, with exceptional quality, and at a lower operational cost is a powerful proposition that drives innovation and competitive advantage.