The narrow-web printing sector faces constant challenges, especially when working with delicate, heat-sensitive films. These materials are vital for many packaging applications, from food and beverage labels to high-tech product identification. Traditional curing methods, often involving high heat or intense UV lamps, can easily damage these substrates. This can lead to warping, shrinking, or even complete material failure, resulting in costly reprints and production delays. Fortunately, advancements in LED flexographic (flexo) printing technology offer a powerful solution.

LED UV curing systems have revolutionized how printers handle challenging substrates. Unlike conventional mercury lamps, LED UV lamps emit light at specific wavelengths. This targeted emission generates significantly less heat. This is a critical advantage when printing on thin, heat-sensitive films commonly used in narrow-web applications. The reduced heat output minimizes the risk of substrate degradation, ensuring print quality and material integrity.

The Advantages of LED UV Curing for Sensitive Films

The primary benefit of LED UV curing in this context is its low-temperature performance. Conventional UV lamps produce a broad spectrum of light, including infrared radiation, which contributes to significant heat buildup. This heat is detrimental to films like PET, BOPP, and even some specialized plastics. LED lamps, however, operate much cooler. They emit light in narrow bands, primarily in the UVA range (365nm, 395nm, 405nm). This focused energy cures the inks efficiently without transferring excessive heat to the film.

This translates directly into improved print quality and process stability. Printers can achieve sharper dots, smoother solids, and better ink adhesion on heat-sensitive films. The risk of static electricity buildup, often exacerbated by heat, is also reduced. This makes material handling smoother and less prone to issues like dust attraction or web breaks. Furthermore, the consistent energy output of LED systems ensures repeatable curing results, batch after batch.

Flexography and LED UV: A Synergistic Partnership

Flexography is a dominant printing process in the narrow-web industry due to its versatility and cost-effectiveness. Its inherent ability to print on a wide range of substrates, including plastics and foils, makes it ideal for label and flexible packaging production. When combined with LED UV curing technology, flexo printing becomes even more potent, especially for demanding applications.

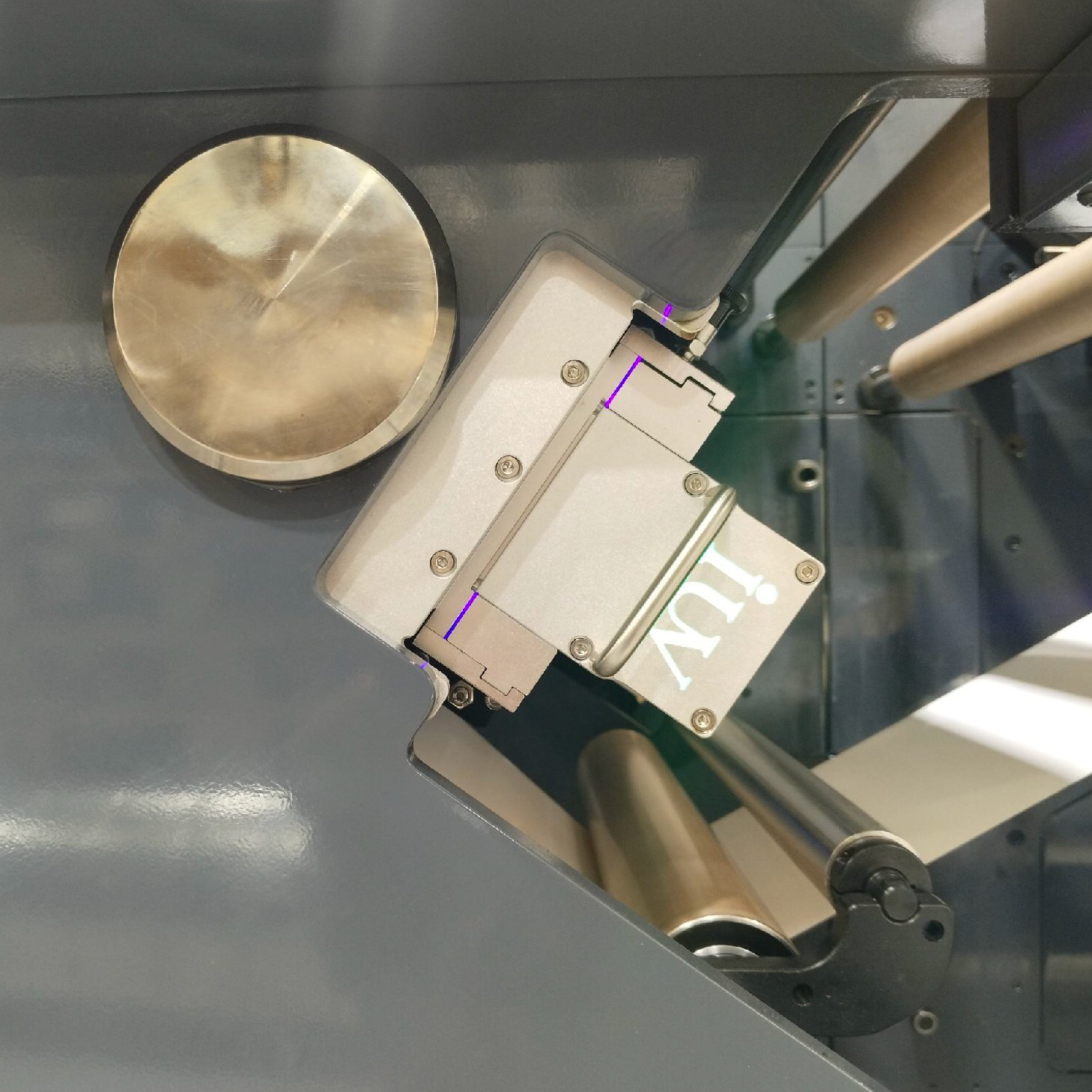

LED flexo units are designed for efficient integration into existing narrow-web presses. They offer near-instantaneous curing of inks and coatings. This allows for faster printing speeds without compromising quality, even on challenging films. The precise control over UV output from LED systems also enables printers to optimize ink laydown and curing for specific film types. This leads to enhanced performance and durability of the printed graphics.

Tackling Specific Challenges with LED Flexo

Heat-sensitive films present unique printing hurdles. For instance, polyethylene terephthalate (PET) films can become brittle or distort if overheated. Polypropylene (PP) films are known for their low surface energy, requiring specialized inks and careful curing. Polyethylene (PE) films, often used in flexible packaging, can deform easily. LED flexo technology addresses these challenges by providing a gentle yet effective curing process.

The low heat emission of LED UV systems prevents the thermal expansion and contraction of films, preserving dimensional stability. This is crucial for applications requiring precise registration, such as multi-layer labels or packaging with intricate designs. The ability to cure inks quickly also helps in achieving a tough, scratch-resistant finish on these flexible substrates, meeting the rigorous demands of end-users.

Ink Formulation and Compatibility

The transition to LED UV curing necessitates a careful look at ink formulations. While traditional UV inks are mercury-curable, LED-curable inks are specifically designed to react to the narrow wavelength outputs of LED lamps. These inks typically contain photoinitiators that are sensitive to UVA light. Developing or selecting the right LED-curable inks is paramount for achieving optimal adhesion and performance on heat-sensitive films.

Formulators have made significant strides in creating LED inks that offer excellent adhesion to challenging substrates like PET, PP, and PE. These inks also provide vibrant color reproduction and good flexibility, essential for packaging applications. Compatibility testing between the ink, the film, and the specific LED UV system is a key step in ensuring a successful printing process. This includes verifying cure speed, adhesion, rub resistance, and flexibility.

The Operational and Environmental Benefits

Beyond print quality, LED UV curing offers substantial operational and environmental advantages. LED lamps have a much longer lifespan compared to mercury lamps, reducing maintenance costs and downtime. They also consume less energy, contributing to lower operating expenses and a reduced carbon footprint.

The instant on/off capability of LED lamps means they only consume power when actively curing. This contrasts with mercury lamps, which require a warm-up period and can be energy-intensive even when not in full use. The absence of mercury in LED lamps also makes them an environmentally friendlier choice, aligning with growing sustainability initiatives in the printing industry. For narrow-web converters, this translates into a more efficient, cost-effective, and eco-conscious printing operation.

Future Trends and Innovations

The integration of LED flexo technology in narrow-web printing is a continuing trend. As demand for high-quality printing on diverse substrates, especially heat-sensitive films, grows, so does the importance of LED UV curing. Innovations in LED lamp design and ink chemistry are continuously pushing the boundaries of what is possible.

We are seeing developments in higher power LED systems for even faster curing speeds. Research is also focused on expanding the spectral output options of LED lamps to cater to a wider range of specialized inks and coatings. The synergy between advanced flexo press technology, optimized LED curing, and specialized ink formulations is paving the way for unprecedented quality and efficiency in narrow-web production, particularly for those challenging heat-sensitive film applications. This evolving landscape promises greater flexibility and capability for label and packaging printers worldwide.