The demand for high-performance labels in the narrow-web sector is constantly growing. Businesses require labels that not only look stunning but also withstand the rigors of product use, handling, and environmental exposure. For digital narrow-web printing, achieving this level of durability has historically presented challenges. However, the advent and widespread adoption of LED UV curing technology have significantly shifted this landscape, offering a powerful solution for enhancing label longevity.

The Evolving Needs of Narrow-Web Labeling

Narrow-web printing, typically encompassing labels and flexible packaging up to 20 inches wide, serves a vast array of industries. From food and beverage to pharmaceuticals and cosmetics, the label is often the first point of contact a consumer has with a product. This means it needs to be visually appealing, convey essential information, and, crucially, remain intact and legible throughout its lifecycle.

Traditional printing methods, while capable, often relied on thermal or oxidative curing inks. These processes could be slow, energy-intensive, and sometimes resulted in inks with inherent vulnerabilities to abrasion, chemicals, or UV light. Digital printing, with its flexibility and short-run capabilities, was particularly eager for a curing solution that matched its agility while delivering superior performance.

Understanding UV Curing: A Foundation for Durability

Before we explore the LED aspect, it’s helpful to understand UV curing itself. UV curing uses ultraviolet light to initiate a photochemical reaction that solidifies (cures) inks, coatings, and adhesives. This process is distinct from drying, where a solvent simply evaporates. Curing creates a cross-linked polymer network, resulting in a hard, durable film.

This rapid, on-demand curing offers several advantages over traditional methods:

- Speed: Curing happens almost instantaneously, increasing press speeds.

- Energy Efficiency: Compared to heat curing, UV systems can be more energy-efficient.

- Reduced VOCs: UV-curable inks and coatings typically contain little to no volatile organic compounds (VOCs), leading to a safer working environment and reduced environmental impact.

- Enhanced Properties: Cured inks often exhibit superior scratch resistance, chemical resistance, and adhesion.

The LED Revolution in UV Curing

While traditional mercury-vapor lamps have been the workhorse of UV curing for decades, Light Emitting Diodes (LEDs) represent a significant technological leap. LED UV curing offers a more targeted, efficient, and controllable form of UV energy.

Here’s how LED UV curing directly impacts and improves the durability of digital narrow-web labels:

1. Consistent and Targeted UV Spectrum

Traditional mercury lamps emit a broad spectrum of UV light, including wavelengths that are not optimally used for curing. This can lead to inconsistent curing and potential degradation of the substrate or ink over time. LEDs, on the other hand, are designed to emit specific wavelengths that precisely match the photoinitiators in UV-curable inks and coatings.

- Benefit for Durability: This precise wavelength delivery ensures that the photoinitiators are activated efficiently and uniformly. The result is a more complete and robust cross-linking of the polymer matrix within the ink. A thoroughly cross-linked film is inherently stronger and more resistant to physical and chemical stresses. This means better scratch resistance, improved rub resistance, and enhanced resistance to common cleaning agents or product contents.

2. Controlled Energy Output and Reduced Heat

LED UV systems offer a high degree of control over the intensity and duration of UV exposure. Unlike mercury lamps that can experience intensity decay and require frequent replacement, LEDs maintain their output for much longer periods. Furthermore, LEDs emit very little infrared radiation (heat) compared to mercury lamps.

- Benefit for Durability: Less heat generated means a lower risk of heat-related damage to the label substrate, especially for sensitive materials like thin films or certain plastics used in narrow-web applications. Substrates that are not subjected to excessive heat are less likely to warp, shrink, or become brittle. This helps maintain the structural integrity of the label itself, contributing to its overall durability. Moreover, the consistent energy output ensures that each label receives the same amount of curing energy, leading to uniform ink properties and predictable durability across the entire print run.

3. Improved Adhesion to Diverse Substrates

One of the challenges in narrow-web printing, particularly with digital technologies, is achieving excellent adhesion to a wide range of substrates, from paper to various plastic films (like PP, PE, PET). The way an ink adheres to a surface is a critical component of its durability.

- Benefit for Durability: The efficient and complete curing enabled by LED UV technology leads to a stronger bond between the ink and the substrate. The complete polymerization ensures that the ink forms a cohesive layer that is well-integrated with the surface. This superior adhesion prevents delamination, peeling, or lifting, even under conditions of flexing, stretching, or exposure to moisture or oils. For labels on flexible packaging or products that are frequently handled, this enhanced adhesion is paramount.

4. Enhanced Chemical and Abrasion Resistance

The cross-linked polymer structure formed during LED UV curing results in a surface that is significantly harder and less permeable than that achieved with other curing methods. This translates directly into improved resistance to everyday wear and tear.

- Benefit for Durability: Labels printed with LED UV cured inks can better withstand accidental spills of chemicals, oils, or solvents commonly found in industrial or household environments. They also exhibit superior resistance to scratching and scuffing from handling, stacking, or the movement of goods. This is particularly important for labels on products like cleaning supplies, automotive fluids, or items that undergo rough handling during shipping and retail.

5. Versatility with Special Effect Inks and Coatings

The narrow-web market increasingly utilizes special effect inks and coatings to make labels stand out. These can include varnishes, metallic effects, and tactile coatings. Ensuring these special finishes are as durable as the primary print is essential for the overall label performance.

- Benefit for Durability: LED UV curing is highly effective with a wide array of UV-curable formulations, including those used for these special effects. The controlled curing process ensures that these coatings cure properly, maintaining their intended aesthetic and providing a protective layer that contributes to the overall durability of the label. For instance, a durable spot varnish applied over printed graphics can protect them from abrasion and add a premium feel without compromising longevity.

LED UV Curing in Digital Narrow-Web Workflows

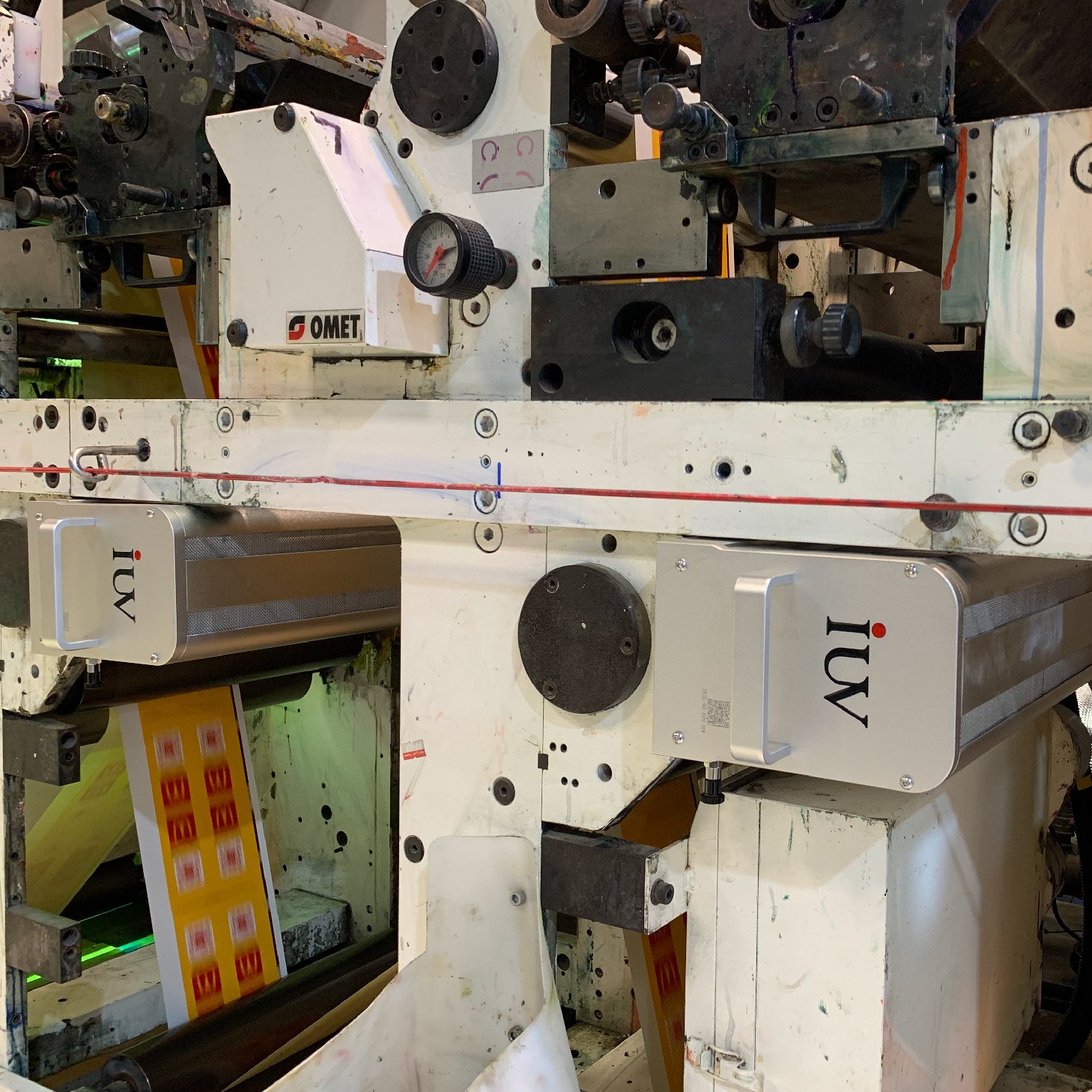

The integration of LED UV curing systems into digital narrow-web printing presses (whether inkjet or toner-based) is seamless. These systems are typically positioned inline, immediately after the printing station. As the label substrate passes under the LED array, the ink or coating is instantly cured.

This inline capability is a significant advantage for digital printing:

- No Drying Time: Eliminates the need for lengthy drying tunnels or waiting periods.

- Immediate Handling: Labels can be wound, cut, or finished immediately after printing, streamlining the entire production process.

- Reduced Floor Space: Compact LED units require less physical space on the press.

- Lower Energy Consumption: LED technology is inherently more energy-efficient, leading to operational cost savings.

Addressing Concerns and Future Outlook

While the benefits are clear, some initial considerations might arise. Ensuring compatibility between the LED UV system’s wavelength output and the specific photoinitiators in the inks is crucial for optimal curing. Reputable ink manufacturers now offer formulations specifically designed for LED UV curing. Furthermore, understanding the correct energy dosage (irradiance and exposure time) is key to achieving desired durability levels.

The future of narrow-web label printing is undeniably linked to advancements in digital technology and curing methods. LED UV curing stands out as a pivotal technology that not only meets but exceeds the increasing demands for label durability. It empowers converters to deliver labels that are visually striking, robust, and long-lasting, providing a competitive edge in a dynamic market.

By choosing digital narrow-web presses equipped with advanced LED UV curing, printers can confidently offer labels that promise superior performance, resilience, and aesthetic appeal, ensuring brand integrity from the moment of production to the end-user experience. This technology is not just an upgrade; it’s a fundamental enhancement to what narrow-web labels can achieve.