The packaging printing industry is constantly seeking ways to optimize operations and reduce turnaround times. One significant bottleneck in this process has been the time required for job changeovers, especially when dealing with specialized finishes like UV coatings. Traditionally, adjusting UV curing systems for different jobs could be a manual and time-consuming endeavor. However, advancements in automation are now revolutionizing this aspect of packaging printing, leading to dramatically faster job changeovers.

The Challenge of UV Curing in Job Changeovers

UV curing technology has become indispensable in packaging printing for several key reasons. It offers instant drying, which allows for faster production speeds and immediate post-processing, such as stacking or die-cutting. UV coatings also provide enhanced durability, scuff resistance, and a high-quality aesthetic finish that is crucial for brand appeal. However, achieving the optimal UV cure often depends on precise control of several parameters:

- UV Lamp Intensity: Different inks, coatings, and substrates require varying levels of UV energy to cure properly. Too little energy results in under-cured, sticky prints, while too much can scorch the substrate or degrade the ink.

- Exposure Time/Speed: The speed at which the substrate passes under the UV lamps directly influences the total energy delivered. This needs to be synchronized with the press speed.

- UV Wavelength: Different UV wavelengths are absorbed more effectively by specific ink and coating formulations. Modern UV systems often offer multiple wavelength options (e.g., Mercury lamps or LED UV with specific wavelength outputs).

- Cooling Systems: High-intensity UV lamps generate significant heat. Effective cooling is necessary to protect the press, substrate, and operators.

In a traditional setting, changing from one job to another, which might involve different colors, coatings, or even substrates, would necessitate manual adjustments to these UV curing parameters. This often involved skilled operators making educated guesses or running test sheets to dial in the settings, adding considerable time and potential material waste to the changeover process.

The Rise of Automated UV Press Adjustments

The integration of automation into UV curing systems addresses these challenges head-on. Automated UV press adjustments allow the press to independently configure its UV system based on pre-programmed job specifications. This significantly reduces or even eliminates manual intervention during changeovers.

How Automation Works in UV Curing

Modern automated UV curing systems typically incorporate several key technologies:

- Sensor Integration: Advanced sensors are often integrated into the UV curing units. These sensors can monitor various aspects of the printing process in real-time, such as substrate temperature, ink density, and even the spectral output of the UV lamps.

- Job Data Management: Printing presses are increasingly connected to workflow management systems. When a new job is loaded into the press, it can automatically retrieve the associated UV curing parameters from the job data. This data can include specific settings for lamp intensity, speed synchronization, and wavelength selection.

- Closed-Loop Control: This is a critical aspect of automation. Closed-loop systems use feedback from sensors to continuously adjust parameters. For instance, if a sensor detects that the substrate temperature is rising too high, the system can automatically reduce the UV intensity or increase the cooling fan speed. Similarly, if ink coverage varies, the system can adjust UV output to ensure consistent curing across the entire print.

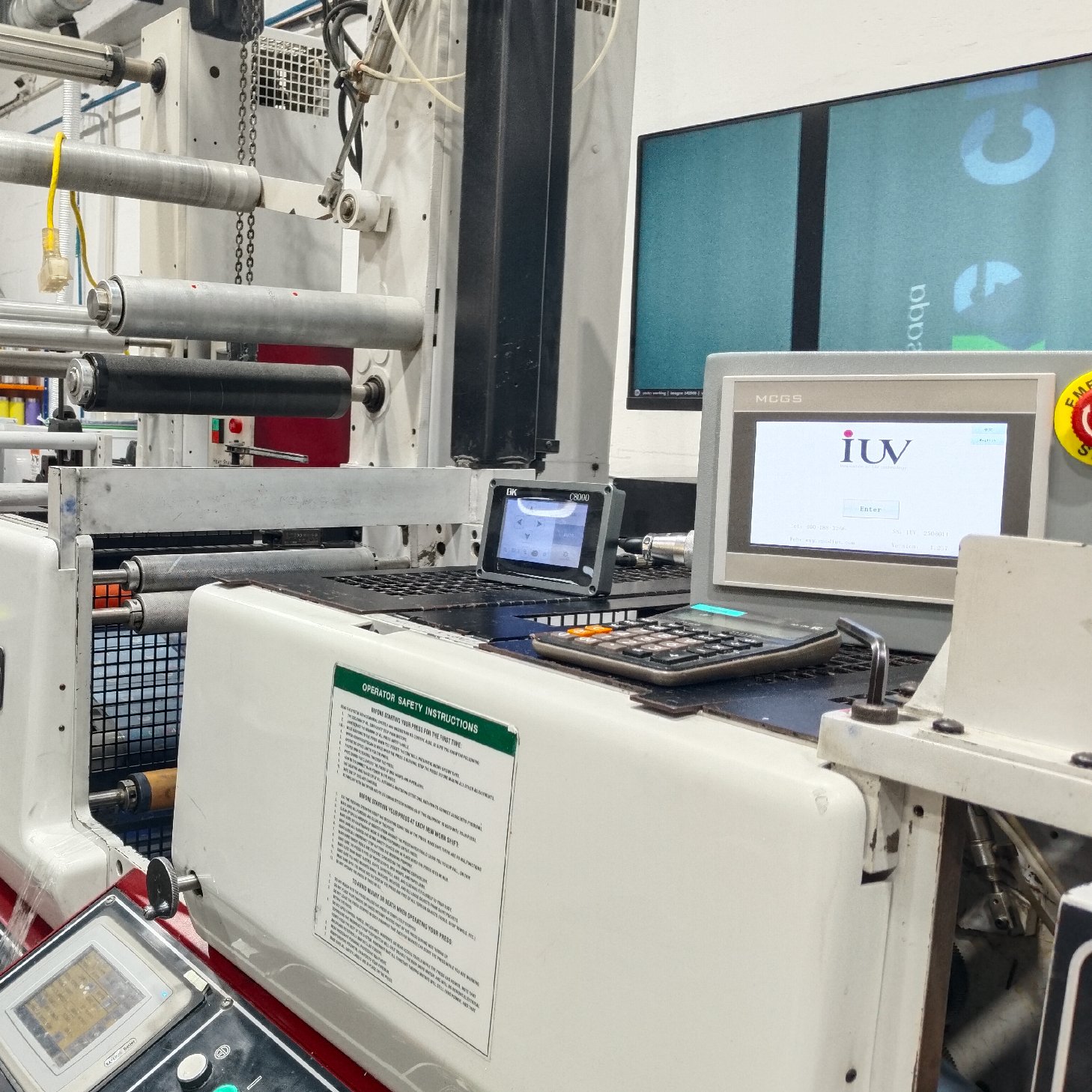

- PLC and HMI Integration: Programmable Logic Controllers (PLCs) are the brains behind these automated systems, executing the programmed logic. The Human-Machine Interface (HMI) provides operators with a visual display and control panel to monitor system status and make any necessary manual overrides.

Benefits of Automated UV Adjustments for Faster Job Changeovers

The impact of automated UV press adjustments on job changeovers is profound and multifaceted, especially in label and narrow web printing, as well as wider packaging applications.

1. Dramatically Reduced Setup Time

This is the most immediate and apparent benefit. Instead of an operator manually adjusting multiple dials or settings on the UV lamps, the press automatically reconfigures the UV system as part of the overall job setup sequence. This can shave minutes, or even tens of minutes, off each changeover, translating directly into increased press uptime and throughput.

2. Enhanced Consistency and Quality

Manual adjustments are prone to human error and variability. Automated systems, governed by precise programming and sensor feedback, ensure that the UV curing parameters are applied consistently for every job. This leads to more reliable curing, fewer instances of under-cured or over-cured products, and a higher overall print quality, job after job.

3. Minimized Material Waste

When operators have to manually dial in UV settings, they often run multiple test sheets to achieve the desired results. This consumes valuable substrate and ink, increasing waste and cost. Automated systems, by applying correct settings from the start, significantly reduce or eliminate the need for these test runs, leading to substantial material savings.

4. Increased Operator Efficiency and Safety

Automated systems free up skilled operators from tedious, repetitive tasks. They can focus on monitoring the overall print quality and managing other aspects of the production process. Furthermore, reducing manual interaction with high-intensity UV lamps enhances operator safety.

5. Greater Flexibility and Responsiveness

With automated UV control, printers can more easily accommodate short-run jobs and handle frequent changeovers without significant productivity penalties. This allows them to be more agile in responding to market demands and customer requests for smaller, more frequent print runs.

Applications in Different Printing Technologies

The benefits of automated UV press adjustments are applicable across various printing technologies commonly used in packaging:

Narrow Web Label Printing

In the label printing sector, job changeovers are often very frequent due to the wide variety of SKUs and short runs. Automated UV systems allow flexographic and offset label presses to switch between different UV-curable inks, varnishes, and adhesives with minimal downtime. This is crucial for high-volume label converters who need to maximize press utilization. The precise control of UV output is also vital for intricate label designs and special effects that rely on perfect curing.

Wide Web Packaging (Flexo and Offset)

For wider format packaging applications, such as flexible packaging and folding cartons printed on flexographic or offset presses, automated UV curing is equally transformative. Handling different film substrates, laminates, and a broad spectrum of inks and coatings requires robust and adaptable curing solutions. Automation ensures that the correct energy is delivered consistently across the web, preventing issues like poor adhesion or premature delamination, which can be catastrophic in flexible packaging.

Sheetfed Offset Printing

In sheetfed offset printing for folding cartons and commercial packaging, automated UV curing systems integrate seamlessly with modern offset presses. Job changeovers involving different ink sets, spot UV coatings, or metallic effects are streamlined. The ability to precisely control UV intensity and exposure for specific areas of the sheet can also enable advanced finishing techniques, like selective high-gloss or matte finishes, without lengthy manual setup.

The Future of UV Curing Automation

The trend towards greater automation in UV curing is set to continue. We can expect to see even more sophisticated sensor technologies, advanced AI-driven optimization algorithms, and tighter integration with digital printing workflows. This will further enhance efficiency, reduce waste, and enable printers to deliver even higher quality packaging solutions with greater speed and flexibility.

The adoption of automated UV press adjustments is no longer a luxury but a necessity for packaging printers looking to remain competitive. By minimizing the time and complexity associated with job changeovers, these technologies unlock significant gains in productivity, quality, and profitability.