The integration of LED UV automation into the label printing process has ushered in a new era of enhanced quality, particularly on challenging substrates like filmic and paper labels. This technological leap is not merely an upgrade; it’s a fundamental shift in how we achieve superior results, offering precision, speed, and consistency that were previously difficult to attain.

The Challenge of Substrates

Printing on filmic materials, such as polyethylene (PE), polypropylene (PP), and polyester (PET), presents unique hurdles. These substrates are often non-porous, meaning inks don’t readily absorb into them. This can lead to issues with ink adhesion, scratch resistance, and drying times. Paper labels, while more traditional, also have their own complexities, including varying absorbency, surface textures, and susceptibility to warping or color changes when exposed to heat or certain curing methods. Achieving vibrant colors, sharp details, and durable finishes on both requires a sophisticated approach.

Understanding UV Curing Technology

Traditional UV curing systems use mercury vapor lamps. While effective, these lamps generate significant heat, can have a limited lifespan, and their spectral output can vary. This heat can be detrimental to sensitive filmic materials, causing shrinkage or distortion. Moreover, the inconsistent output can affect ink cure levels, leading to variability in print quality and performance.

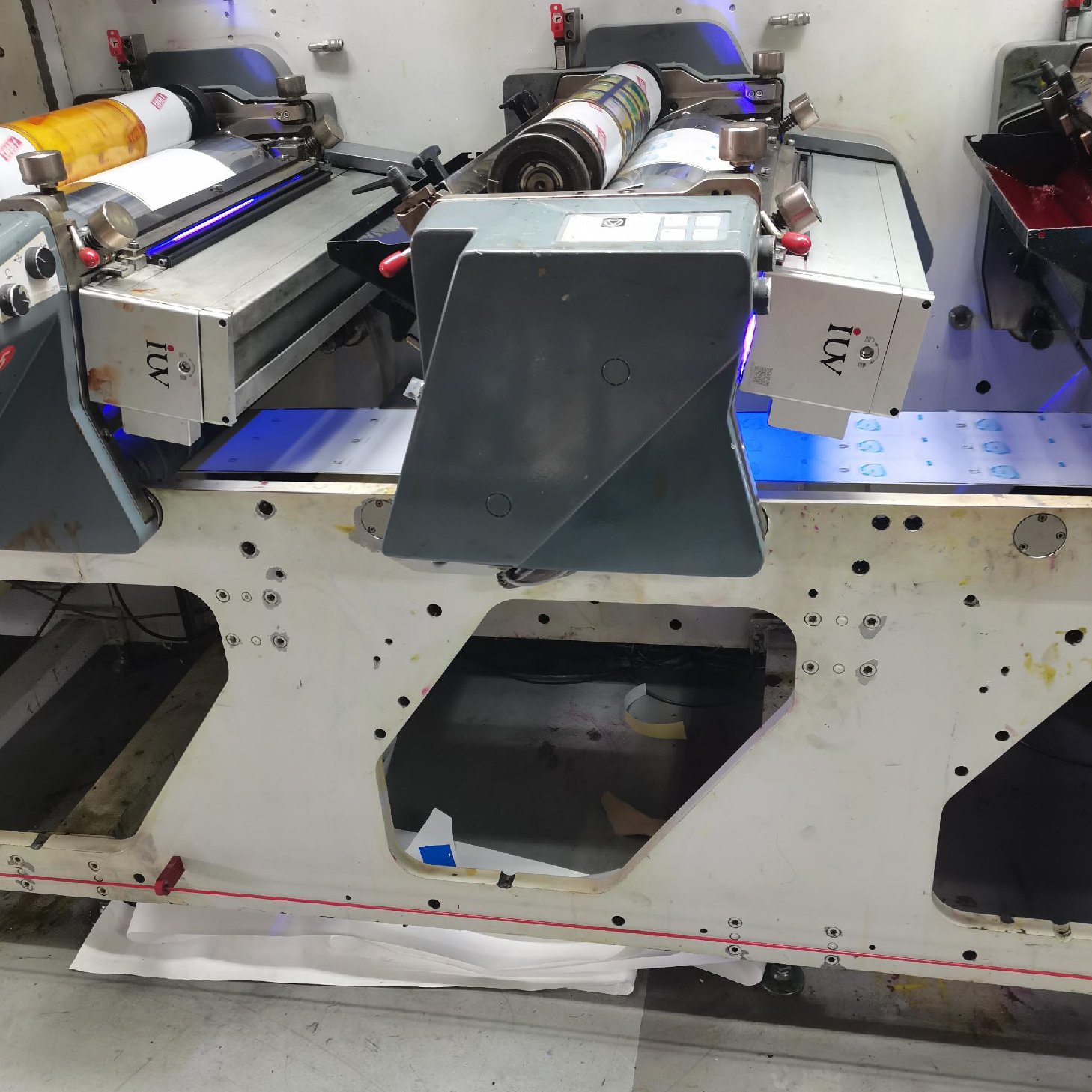

LED UV curing technology represents a significant advancement. Instead of a broad spectrum of UV light, LEDs emit a narrow, specific wavelength of UV energy. This targeted approach offers several distinct advantages:

- Lower Heat Emission: LEDs produce far less heat than mercury lamps. This is crucial for printing on heat-sensitive filmic substrates, preventing distortion and maintaining dimensional stability.

- Instant On/Off: LEDs switch on and off instantaneously. This means no warm-up or cool-down period is required, leading to immediate energy savings and faster job changeovers.

- Longer Lifespan: LED lamps have a significantly longer operational life compared to mercury lamps, reducing maintenance costs and downtime.

- Consistent Output: LEDs offer a stable and consistent UV output over their lifespan, ensuring uniform and reliable ink curing from the first label to the last.

- Energy Efficiency: LEDs consume less energy than traditional UV lamps, contributing to lower operating costs and a smaller environmental footprint.

Automation’s Role in Enhancing Quality

Automation, when coupled with LED UV curing, amplifies these benefits and introduces new layers of quality control. Automation encompasses the integration of various components and processes, from ink delivery and color management to press operation and, crucially, the precise control of the LED UV curing units.

In the context of label printing, automation ensures:

- Precise Ink Application: Automated ink systems deliver the exact amount of ink needed for each color, preventing over-inking (which can lead to muddiness and loss of detail) or under-inking (which results in weak color strength). This precision is vital for achieving consistent ink laydown, especially in multi-color applications.

- Consistent Color Management: Automated color registration systems ensure that each color unit on the press is perfectly aligned. This eliminates ghosting and ensures sharp, well-defined graphics and text. When combined with LED UV, the consistent curing of each ink layer prevents color shift or degradation that can occur with uneven drying.

- Optimized Curing Parameters: Automated control of LED UV units allows for precise adjustment of intensity and exposure time based on ink type, substrate, and press speed. This ensures that the ink is fully cured without being over-cured, which can sometimes make inks brittle. This is particularly important for achieving the required rub and scratch resistance on labels that will undergo significant handling.

- Reduced Operator Error: Automation minimizes the human element, reducing the likelihood of errors in setup, operation, and quality checks. This leads to greater consistency batch after batch.

LED UV Automation in Specific Printing Processes

The benefits of LED UV automation are profoundly felt across various label printing methods:

Flexographic Printing (Flexo)

Flexography is a workhorse for label printing, especially for narrow-web applications. In flexo, raised plates transfer ink to the substrate. LED UV curing is ideal here because it allows for faster press speeds, a critical factor in high-volume label production. The instant curing prevents ink from smudging or transferring to anilox rolls or blankets, which can happen with slower-drying inks. Automation ensures consistent ink transfer and registration, while LED UV guarantees a perfect cure, resulting in crisp dot gain, vibrant spot colors, and excellent adhesion on both paper and films.

Offset Lithographic Printing (Offset)

While traditionally associated with sheet-fed printing, offset lithography is also used in narrow-web label printing. Offset relies on the principle of ink and water repulsion. LED UV inks cure by photo-initiation, meaning they solidify rapidly upon exposure to UV light. Automation in offset helps maintain precise ink-water balance and precise transfer. LED UV curing ensures that the ink forms a durable, non-porous film on the substrate, enhancing scuff resistance and gloss, even on glossy or coated paper stocks and films.