The rise of short-run, multi-version label production presents a dynamic challenge for modern printers. As brands increasingly demand customization and faster turnaround times for diverse product lines, the traditional methods of label printing often struggle to keep pace. This is where automated UV printing, particularly with LED UV curing technology, emerges as a significant enabler, offering unparalleled flexibility and efficiency.

The Evolving Landscape of Label Demands

The market for labels is no longer a monolithic entity. Today’s consumers expect products tailored to their specific needs and preferences. This translates directly into a demand for labels that are not only visually appealing but also varied. Think of seasonal promotions, regional variations, personalized product lines, and limited editions. Each of these scenarios requires the production of numerous, often small, batches of labels that are distinct from one another.

Limitations of Conventional Printing for Short Runs

Traditional printing methods like flexography and offset printing, while excellent for long runs, can be inefficient and costly when dealing with short-run, multi-version jobs. The setup times, including plate changes, ink adjustments, and color calibration, are significant. For each new version of a label, these setup processes must be repeated, eating into production time and increasing waste. This can make it economically unviable to produce highly customized or short-run labels, forcing businesses to either compromise on their marketing strategies or incur prohibitive costs.

Introducing Automated UV Printing

Automated UV printing systems are designed to address these very limitations. The “automated” aspect refers to the streamlined workflow, from pre-press to finishing, minimizing manual intervention. This automation is critical for efficiently handling the rapid changeovers required for multi-version jobs.

At the heart of this technology is ultraviolet (UV) curing. Instead of relying on heat or air to dry ink, UV printing uses specialized UV lamps to instantly cure (harden) the ink as it is applied to the substrate. This process offers several key advantages:

- Instant Drying: UV inks cure almost instantaneously upon exposure to UV light. This means that labels can be immediately moved to the next stage of production or finishing without the risk of smudging or ink transfer.

- Versatility of Substrates: UV inks adhere well to a wide range of materials, including paper, films, and even some plastics, which are commonly used in label applications. This broad substrate compatibility is essential for meeting diverse product requirements.

- Vibrant Color Reproduction: UV inks are known for their ability to produce sharp, vibrant, and durable prints. This ensures that even short-run labels maintain high visual quality.

The Power of LED UV Curing

While traditional UV curing lamps have been around for a while, the advent of Light Emitting Diode (LED) UV curing technology has propelled automated UV printing to a new level. LED UV lamps offer distinct benefits over conventional mercury vapor lamps:

- Energy Efficiency: LEDs consume significantly less energy, leading to lower operating costs and a reduced environmental footprint.

- Longer Lifespan: LEDs have a much longer operational life than traditional UV lamps, reducing maintenance and replacement expenses.

- Instant On/Off: LEDs can be switched on and off instantaneously, which is ideal for print jobs with frequent start-stop cycles and for precisely controlling curing zones, further minimizing energy consumption and heat exposure to the substrate.

- Lower Heat Emission: LEDs emit less infrared radiation (heat) compared to mercury lamps. This is crucial for printing on heat-sensitive substrates, preventing warping or damage that could occur with excessive heat.

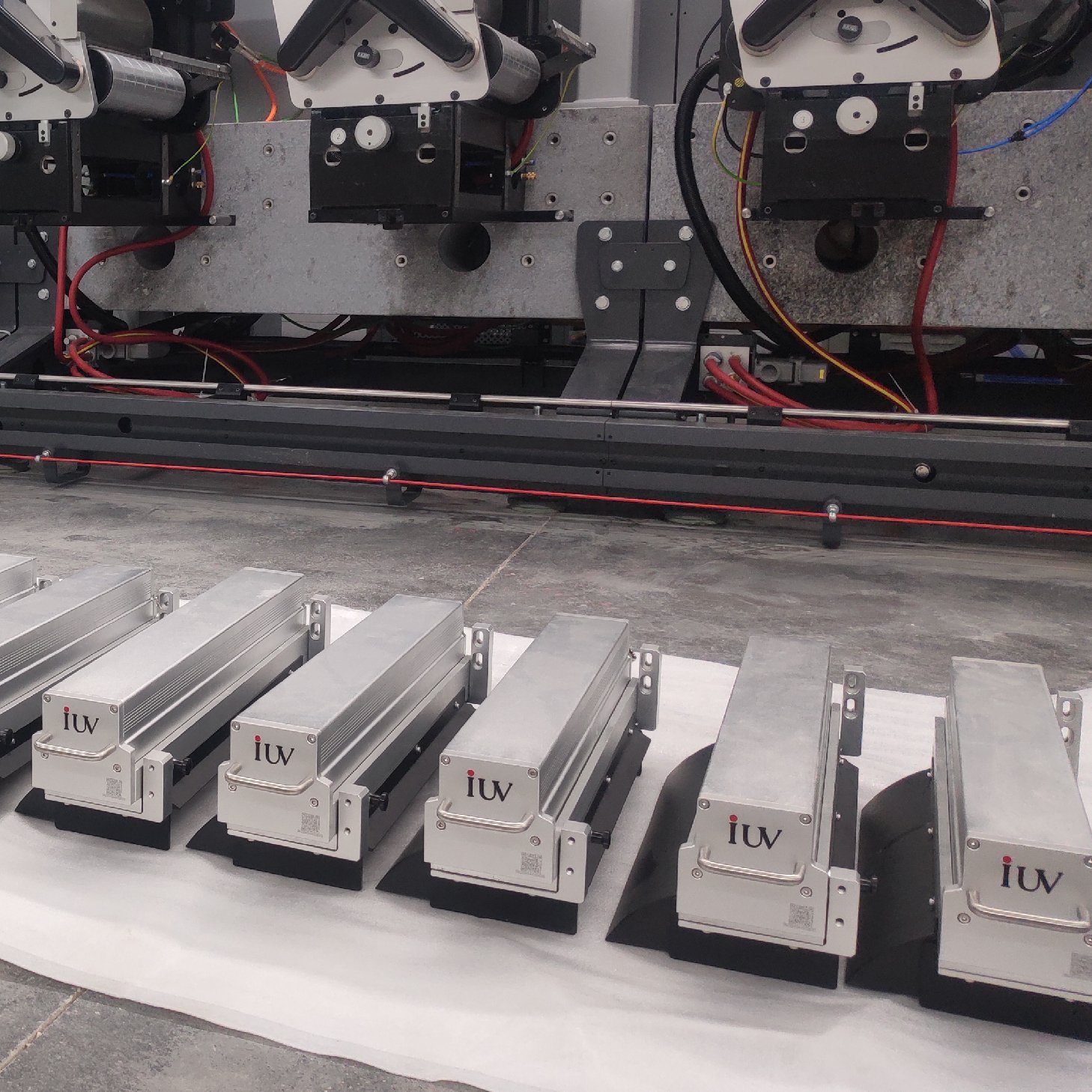

- Compact Size: The smaller profile of LED lamps allows for more flexible integration into narrow web printing presses.

How Automation and UV Curing Combine for Short-Run Success

The synergy between automation and LED UV curing in narrow web printing presses creates a powerful solution for short-run, multi-version label production:

- Rapid Job Changeovers: Automated systems allow for quick digital setup and adjustments. Without the need to change physical plates or extensively recalibrate inks, printers can switch from one label version to the next in a matter of minutes, or even seconds, depending on the press’s capabilities.

- Reduced Waste: The instant curing of UV inks and precise digital control minimize ink waste and substrate spoilage during setup and production. This is particularly beneficial for short runs where waste can represent a significant portion of the overall cost.

- On-Demand Production: The efficiency of automated UV printing enables “on-demand” label production. This means that labels can be printed as needed, reducing the need for large inventories and the associated risks of obsolescence or overstocking.

- Cost-Effectiveness for Small Batches: By minimizing setup times and waste, automated UV printing makes producing small quantities of labels economically viable. This opens up new market opportunities for printers and allows their clients to experiment with more diverse labeling strategies.

- Flexibility in Design and Varnish: UV inks and coatings can be applied in various ways, including spot varnishes, textured finishes, and metallic effects, all of which can be managed digitally within an automated workflow. This adds significant value and brand appeal to short-run labels.

- Narrow Web Printing Press Integration: The compact nature of LED UV curing systems makes them ideal for integration into narrow web flexographic and digital printing presses, the workhorses of the label industry. This allows for efficient, in-line production of complex labels.

Applications in Various Printing Technologies

- Narrow Web Flexography: While traditionally plate-based, modern narrow web flexo presses are increasingly incorporating automated plate-mounting systems and digital color management. When paired with LED UV curing units, these presses can achieve much faster changeovers for short-run, multi-version jobs, especially if using digital prepress workflows that minimize plate changes per job.

- Digital Printing: For true short-run and highly variable data printing (VDP), digital label presses are unparalleled. Most modern digital label presses heavily rely on UV curing (often LED UV) to instantly dry the ink, enabling high-speed production and immediate post-press processing. The digital nature inherently supports multi-version production without any setup penalties.

- Offset Printing (Sheet-fed and Web-fed): While less common for the tightest of short-run label needs compared to narrow web, some sheet-fed and web offset presses can also be equipped with UV or LED UV curing. Automation in these environments focuses on makeready times and plate handling, making them more competitive for mid-range short runs where the quality of offset is desired.

Addressing the “How” of Multi-Version Production

Consider a scenario where a beverage company wants to launch a new product with labels for different regions, each with a unique promotional message, and a limited-edition run featuring fan-submitted artwork.

With an automated UV printing setup:

- The design files for each version are loaded directly into the press’s digital workflow.

- As soon as one version is completed, the press automatically adjusts for the next version – perhaps a different ink sequence or a variable data element – with minimal downtime.

- The LED UV lamps instantly cure the ink on each label as it passes under them, ensuring that the print is dry and ready for inspection or finishing immediately.

- This allows the printer to efficiently produce all the different versions without significant delays or increased costs associated with traditional methods.

The Future of Label Production

The demand for personalized, varied, and rapidly produced labels is only expected to grow. Automated UV printing, powered by the advancements in LED UV curing technology, is not just a solution; it is becoming the standard for label printers looking to thrive in this evolving market. It empowers them to offer greater flexibility, faster turnaround times, and cost-effective production for short-run, multi-version jobs, ultimately enabling brands to connect with their consumers in more meaningful and dynamic ways.