Traditional UV curing methods often rely on mercury vapor lamps, which are energy-intensive and generate considerable heat. These lamps also have a shorter lifespan and require frequent replacement. Automated LED UV systems, on the other hand, utilize light-emitting diodes (LEDs) that are highly energy-efficient, long-lasting, and offer precise control over the curing process.

Energy Efficiency in Narrow Web and Label Printing

In the realm of narrow web and label printing, speed and efficiency are paramount. Automated LED UV curing systems allow for faster print speeds without compromising on cure quality. The instant on/off nature of LEDs means energy is only consumed when printing is actively occurring, unlike mercury lamps that need to warm up and stay on. This leads to substantial energy reductions, especially in environments where presses may cycle on and off frequently throughout the day.

The focused spectral output of LED UV lamps also means less wasted energy. They emit light within a narrow wavelength band that is highly effective for curing specific UV inks and coatings. This targeted approach minimizes heat generation, which is a significant advantage for heat-sensitive substrates commonly used in label printing. Reduced heat also means less demand on HVAC systems within the print shop, further contributing to overall energy savings.

Flexographic Printing and LED UV Advantages

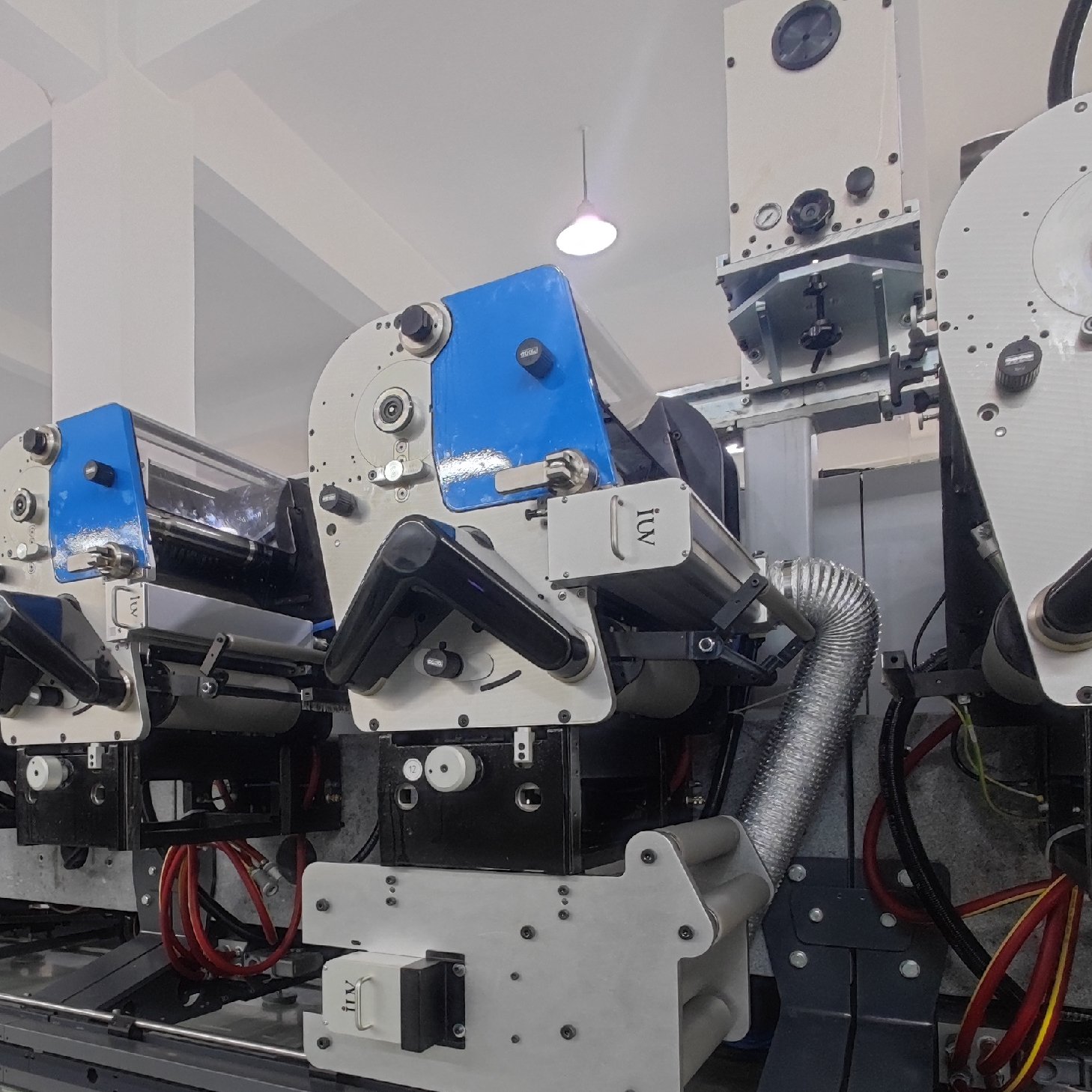

Flexographic printing, widely used for packaging and labels, benefits immensely from the controlled energy delivery of LED UV technology. The ability to achieve a full cure at high speeds ensures vibrant colors and durable prints, even on flexible materials. Automated LED UV systems integrate seamlessly into flexo presses, providing consistent curing across the web width.

The lower heat output from LED UV lamps is a major plus for flexographic printing. It reduces the risk of substrate distortion or shrinkage, ensuring dimensional stability and accurate registration. This consistency translates to less waste and higher quality output. Furthermore, the absence of ozone generation, a byproduct of mercury lamps, improves the working environment and eliminates the need for extensive ventilation systems, saving more energy.

Offset Printing and Energy Conservation

While offset printing traditionally uses different drying methods, LED UV curing is increasingly being adopted, especially in sheetfed operations for specific applications. Automated LED UV systems can be retrofitted or integrated into new offset presses. The energy savings here stem from the same principles: highly efficient light emission and minimal heat.

For offset printers, the immediate curing capabilities of LED UV allow for faster job turnaround times and immediate post-processing, such as stacking or die-cutting. This operational efficiency indirectly contributes to energy savings by reducing idle machine time. The precise control over UV intensity and wavelength ensures optimal ink and coating performance, reducing the need for re-runs due to curing issues.

The Role of Automation

The “automated” aspect of LED UV systems is crucial for maximizing energy savings. These systems can be programmed to activate only when the print head is running and to shut down automatically during press stops or job changes. This intelligent energy management is a significant departure from older technologies where lamps might remain energized unnecessarily.

Smart Energy Management

Modern automated LED UV systems often feature advanced control interfaces that allow printers to fine-tune curing parameters for different jobs and substrates. This level of control ensures that only the necessary amount of energy is used for a perfect cure, preventing over-curing which wastes energy and can degrade ink or substrate.

Reduced Maintenance, Reduced Consumption

The longevity of LED UV lamps also plays a role in energy conservation. With lifespans often exceeding 20,000 hours, they require far less frequent replacement than mercury lamps. This reduces the energy consumed in manufacturing and transporting replacement lamps, and it also minimizes downtime associated with lamp changes, further optimizing operational energy use.

Quantifiable Energy Savings

While specific savings vary depending on the press, application, and operational practices, studies and industry reports consistently show significant energy reductions. Many print shops report savings of 50% to 80% on their UV curing energy consumption after switching to LED UV technology. This translates directly to lower electricity bills and a reduced carbon footprint.

Cost-Benefit Analysis

The initial investment in automated LED UV curing systems may be higher than traditional systems, but the long-term operational cost savings, particularly in energy consumption, are substantial. The reduced waste, increased productivity, and improved print quality further enhance the return on investment.

Environmental Impact and Sustainability

Beyond direct energy cost savings, automated LED UV curing aligns with broader sustainability goals. By consuming less electricity, print shops reduce their reliance on fossil fuels and lower their greenhouse gas emissions. This shift positions businesses as environmentally responsible, which can be a significant competitive advantage in today’s market.

The absence of ozone and mercury in LED UV systems also contributes to a safer and cleaner working environment, eliminating the need for hazardous waste disposal associated with mercury lamps.

Future Trends

The evolution of LED UV technology continues, with advancements focusing on even greater energy efficiency, broader spectral capabilities for curing new ink formulations, and enhanced integration with digital printing workflows. As the printing industry increasingly prioritizes sustainability and operational excellence, automated LED UV curing is set to become the standard, driving further innovation and energy savings across all print segments.

In conclusion, the adoption of automated LED UV operations in modern print shops is not merely a technological upgrade; it’s a strategic move towards greater energy efficiency, reduced operational costs, and enhanced environmental stewardship. This technology offers tangible benefits for narrow web, label, flexographic, and offset printing, paving the way for a more sustainable and profitable future in the print industry.