The label printing industry thrives on speed and efficiency. In narrow web printing, particularly with flexographic processes, minimizing downtime between jobs is paramount. This is where workflow automation and UV flexo printing technologies converge to create powerful solutions. Specifically, the integration of LED UV curing systems dramatically accelerates the transition from one job to the next.

Flexographic printing, often called flexo, is a versatile method well-suited for printing on a variety of substrates. Its flexible printing plates and fast-drying inks make it ideal for packaging and labels. In the realm of narrow web printing, where machines handle materials typically under 20 inches wide, precision and speed are critical. Companies that can switch between different label designs or product runs quickly gain a significant competitive edge.

The Flexo Bottleneck: Job Changeovers

Historically, job changeovers in flexo printing have been a major bottleneck. This process involves several steps: removing the old printing plate, cleaning the anilox roll, mounting the new plate, setting the impression, and adjusting ink flow. Each of these steps requires manual intervention and meticulous attention to detail. Even small errors can lead to waste and further delays.

Consider the traditional method. A press operator might spend considerable time physically unmounting and mounting printing plates. Cleaning the anilox roller, a crucial component that meters ink, can also be time-consuming. Furthermore, achieving the correct ink density and registration on the new job often involves trial-and-error printing, consuming valuable substrate and ink. These cumulative delays directly impact production output and profitability.

Enter UV Flexo: A Leap Forward in Curing

The advent of UV (ultraviolet) curing technology revolutionized printing. Unlike conventional inks that rely on evaporation to dry, UV inks polymerize, or harden, almost instantaneously when exposed to UV light. This rapid curing allows for faster press speeds and the ability to print on non-porous substrates like plastics and foils.

Initially, mercury vapor lamps were the standard for UV curing. While effective, these lamps consumed significant energy, generated substantial heat, and had a limited lifespan, requiring frequent replacement. They also presented environmental concerns due to their mercury content.

The LED UV Revolution: Efficiency and Speed

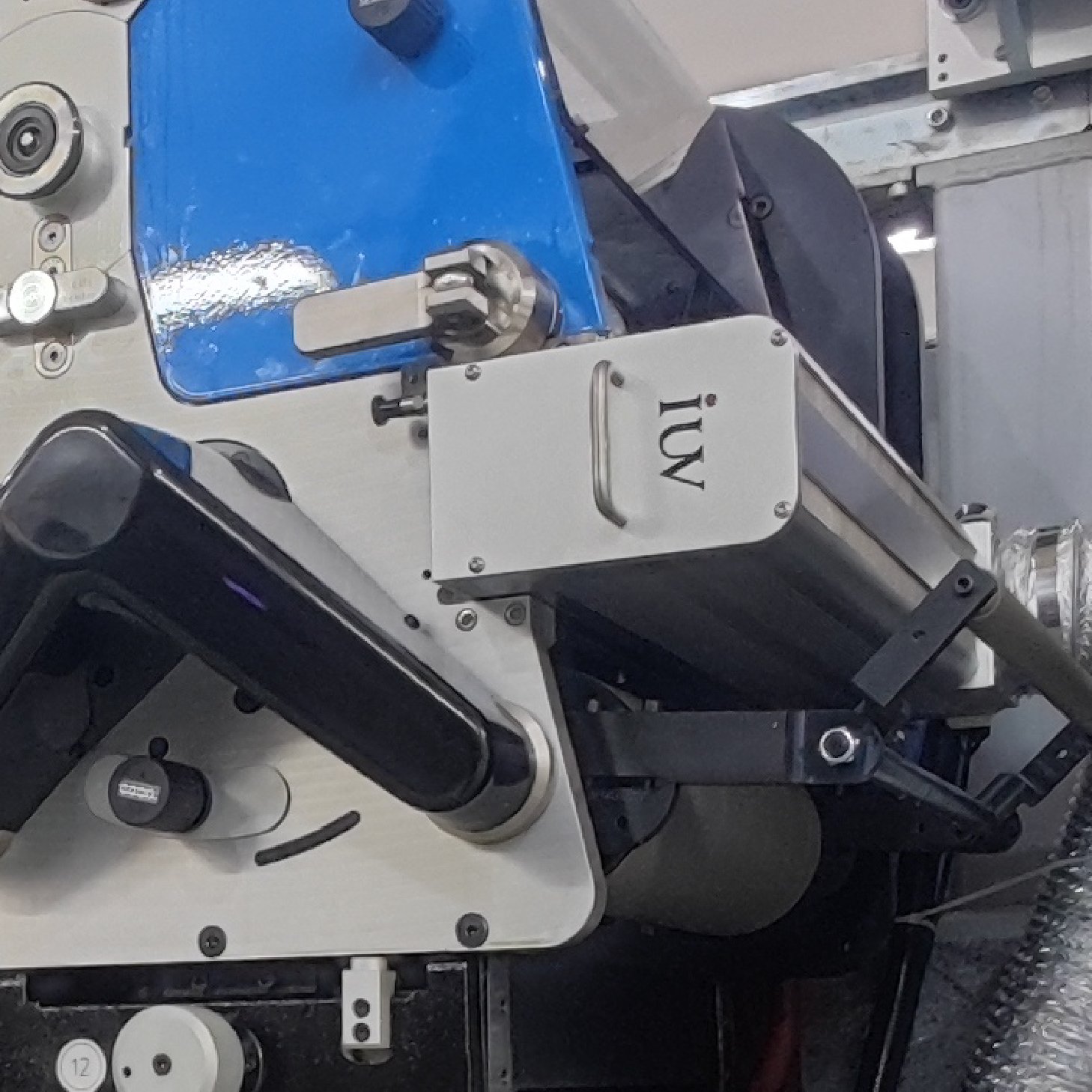

The introduction of LED UV curing systems marked another significant advancement. LED (light-emitting diode) technology offers several key advantages over traditional mercury lamps. First, LEDs are far more energy-efficient, consuming a fraction of the power. Second, they generate very little heat, which is crucial for heat-sensitive substrates and helps maintain a stable printing environment. Third, LEDs have an exceptionally long operational life, reducing maintenance and replacement costs.

Crucially for job changeovers, LED UV systems offer instant on/off functionality. This means the lamps are only active when needed, contributing to energy savings and a cooler press. More importantly, the rapid and consistent curing provided by LEDs means printed materials are dry and ready for the next process or rewinding immediately after passing under the lamp. This eliminates the need for extensive cooling or drying zones, which take up valuable press space and add to setup complexity.

Automation: The Key to Unleashing Full Potential

While UV flexo printing, especially with LEDs, significantly speeds up the curing process, true workflow automation transforms job changeovers from a manual ordeal into a streamlined operation. Automation in this context refers to the integration of technologies that reduce or eliminate manual intervention in repetitive tasks.

Key areas where automation impacts job changeovers in UV flexo printing include:

- Automated Plate Mounting: Advanced systems can automatically register and mount printing plates onto sleeves or cylinders. This drastically reduces the time and skill required for plate setup. Some systems use vision inspection to ensure precise placement.

- Automated Anilox Roll Cleaning and Changes: While full automation here is complex, some presses incorporate automated cleaning cycles or quick-change systems for anilox rolls, reducing manual cleaning time and ink contamination risks.

- Automated Ink Management Systems: These systems precisely control ink viscosity and delivery, ensuring consistent ink laydown from the start of a new job. They can automatically adjust ink levels and color density based on pre-set parameters or real-time feedback from color measurement devices.

- Automated Registration Control: Modern presses feature sophisticated camera systems that monitor print registration in real-time. If the print drifts out of alignment, the system automatically makes minute adjustments to the impression cylinders, eliminating the need for manual intervention and wasted prints.

- Automated Web Tension Control: Maintaining consistent web tension is vital for print quality. Automated systems ensure the correct tension is applied and maintained throughout the run, regardless of the substrate or press speed, contributing to a smoother changeover.

- Pre-set and Recipe Management: Digital workflows allow for the storage of job parameters (ink settings, press speeds, registration targets, curing intensity, etc.) as digital “recipes.” When a new job is loaded, the press can automatically recall and apply these settings, drastically reducing the manual input required by the operator.

The Synergy: LED UV and Workflow Automation

The real magic happens when LED UV curing is combined with these automated workflow elements. The instant curing capability of LEDs means that once automated systems have set up the print, the first printed labels are dry and ready for inspection or further processing almost immediately. There’s no waiting for inks to dry or for cooling.

This synergy allows for:

- Drastically Reduced Setup Times: Operators can transition from one job to the next in minutes, not hours. This allows for more frequent, smaller production runs to be economically viable.

- Minimized Waste: Precise automated controls and rapid curing mean fewer wasted sheets or rolls due to registration errors, ink issues, or drying problems.

- Increased Press Uptime and Throughput: More time spent printing and less time changing over directly translates to higher overall productivity and the ability to fulfill more orders within a given timeframe.

- Improved Consistency and Quality: Automation removes human variability, leading to more consistent print quality across all jobs and repeat orders. LED UV’s consistent curing further reinforces this.

- Operator Empowerment: By automating tedious tasks, operators can focus on higher-level activities like quality control, process optimization, and machine maintenance, rather than just manual setup.

Practical Applications in Narrow Web Printing

Consider a typical scenario in a label printing operation. A press might be running a large batch of one label design for a beverage company. Within a few hours, the order is complete. The operator then needs to switch to a different, smaller run for a specialty food product.

With an automated UV flexo workflow:

- The operator initiates the new job setup via the press interface, selecting the job’s digital recipe.

- Automated plate mounting systems quickly position the new plates.

- The ink management system primes the anilox rolls with the correct colors and viscosity.

- Automated registration systems make fine adjustments as the web starts moving.

- The LED UV lamps activate, instantly curing the ink.

- Within a few meters of printed material, the new job is running correctly, and the waste is minimal.

This process is significantly faster and less prone to errors than manually adjusting each parameter. This efficiency is critical for companies handling a diverse range of labels with varying run lengths.

The Future is Automated and UV-Cured

The trend towards shorter print runs, customization, and faster turnaround times in the packaging and label industries continues to grow. Workflow automation, powered by advanced technologies like LED UV curing, is not just a desirable feature but a fundamental requirement for staying competitive in narrow web flexo printing.

By investing in automated solutions for plate handling, ink management, registration, and by leveraging the efficiency and speed of LED UV curing, printing companies can unlock new levels of productivity, reduce operational costs, and deliver exceptional value to their customers. The integration of these technologies is paving the way for a more agile, efficient, and profitable future in the printing industry.