The label printing industry is constantly evolving. Businesses today demand flexibility, speed, and cost-effectiveness, especially for short-run production. Traditionally, achieving these goals in label printing presented significant challenges. Long setup times and high material waste associated with conventional methods made small batches economically unviable. However, a paradigm shift is underway, driven by the advancements in narrow-web digital label printing, particularly when integrated with modern LED UV curing technology. This combination is not just an incremental improvement; it’s a transformative force accelerating short-run production and opening new avenues for businesses of all sizes.

The Limitations of Traditional Label Printing for Short Runs

For decades, flexographic (flexo) and offset printing have been the workhorses of the label industry. Flexo printing, known for its speed and efficiency on long runs, relies on custom-made printing plates. Each color requires a separate plate, and the process of mounting these plates on the press, making adjustments, and running initial waste sheets to achieve color accuracy can be time-consuming and costly. This inherently makes short runs, where the setup cost is amortized over fewer labels, prohibitively expensive.

Offset lithography, while offering excellent print quality and detail, shares similar limitations. It also requires plates and extensive make-ready time. The cost and complexity of producing plates for even short print jobs mean that businesses often had to commit to larger print volumes than they actually needed, leading to increased inventory, potential obsolescence, and tied-up capital. These methods are optimized for high-volume, long-run production where the per-unit cost decreases significantly with scale.

Enter Digital Printing: A Game Changer for Short Runs

Digital label printing bypasses many of the traditional barriers to short-run production. Instead of physical plates, digital presses use digital data to transfer ink directly onto the substrate. This eliminates the need for plate creation and mounting, dramatically reducing setup times from hours to mere minutes. The ability to print directly from digital files means that artwork can be changed on the fly, making it incredibly easy to produce multiple versions of a label, personalize them, or simply run small batches without significant cost penalties.

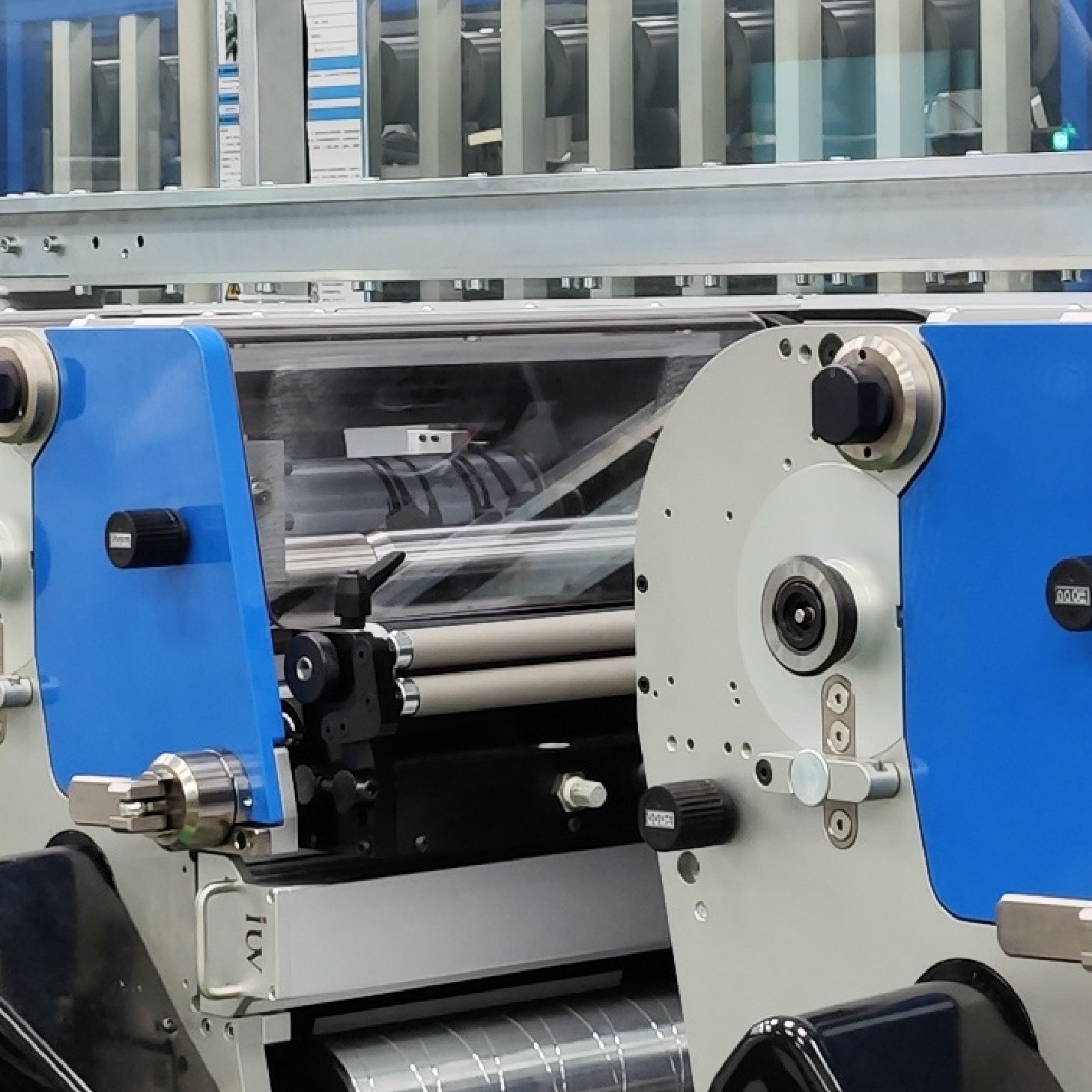

Narrow-web digital presses are specifically designed for the label and packaging sector, typically handling web widths of up to 20 inches (500mm). This focused design allows for efficient use of materials and a streamlined production workflow. For short runs, this translates directly into faster turnaround times and lower overall costs. A print job that might have taken days to set up and run on a flexo press can now be completed within hours. This agility allows businesses to react quickly to market demands, test new product variations, or fulfill urgent orders with unprecedented ease.

The Crucial Role of LED UV Curing

While digital printing itself revolutionized short-run capabilities, its full potential is unlocked through advanced curing technologies, with LED UV curing standing out. In traditional printing, inks need to be dried or cured. For digital presses, this is a critical step that happens almost instantaneously.

Historically, UV curing used mercury vapor lamps. These lamps are energy-intensive, generate significant heat, and have a limited lifespan, requiring frequent replacement. They also emit ozone and pose disposal challenges. The introduction of LED UV curing has addressed these drawbacks head-on.

LED UV curing utilizes light-emitting diodes to emit ultraviolet light. This technology offers several key advantages that are particularly beneficial for narrow-web digital printing and short-run production:

- Instant Curing: LEDs provide instant, high-intensity UV light exactly where and when it’s needed. This allows digital printing presses to run at very high speeds without ink smudging or bleeding. The ink cures almost immediately as it is applied to the substrate.

- Energy Efficiency: Compared to traditional mercury lamps, LEDs consume significantly less energy. This reduces operating costs and contributes to a more sustainable printing process.

- Lower Heat Output: LEDs generate much less heat than mercury lamps. This is crucial for printing on heat-sensitive substrates, which are common in the label industry. It also improves the working environment on the press.

- Longer Lifespan: LED lamps have a much longer operational lifespan, often tens of thousands of hours, reducing maintenance downtime and replacement costs.

- Environmental Benefits: LEDs do not contain mercury and produce no ozone, making them a more environmentally friendly curing solution.

- On-Demand Operation: LEDs can be switched on and off instantaneously, meaning they only consume energy when printing is actively occurring, further enhancing efficiency.

Accelerating Short-Run Production with Digital and LED UV

The synergy between narrow-web digital printing and LED UV curing is what truly accelerates short-run production. Here’s how:

- Reduced Make-Ready Time: As mentioned, digital eliminates plates. With LED UV, there’s no need for lamps to warm up or cool down. The press is ready to print almost immediately after the digital file is loaded, drastically cutting down the time between job conception and finished product.

- Faster Print Speeds: The instant curing provided by LED UV allows digital presses to achieve impressive printing speeds, even with demanding ink formulations. This means that even though a digital press might have a different speed profile than a high-volume flexo press, the overall job completion time for short runs is significantly reduced due to the elimination of setup and faster actual printing.

- Wider Substrate Compatibility: The low heat output of LED UV allows printers to use a broader range of materials, including thin films, foils, and recycled papers, without warping or damaging them. This flexibility is invaluable for short-run jobs that often require specialized or unique substrates.

- Enhanced Durability and Quality: LED UV-curable inks create durable, scratch-resistant, and chemical-resistant labels. This ensures high-quality output that meets the demands of various end-use applications, even for smaller print runs.

- Cost-Effectiveness: For short runs, the elimination of plate costs, reduced waste, lower energy consumption, and faster turnaround all contribute to a more competitive pricing structure. Businesses can now afford to print exactly what they need, when they need it, without the financial burden of large minimum order quantities.

- Versatility and Customization: Digital printing excels at variable data printing (VDP). This means each label can be unique – ideal for promotional campaigns, serialized products, or personalized packaging. LED UV curing ensures these variable elements are instantly durable.

- Streamlined Workflow: The entire process from file submission to finished label is more integrated. With digital files, pre-press is simplified. Instant curing means immediate handling and finishing, reducing bottlenecks and allowing for rapid fulfillment.

Applications and Market Impact

The impact of this technological combination is far-reaching. For brand owners, it means greater agility in bringing new products to market, the ability to test different packaging designs cost-effectively, and the capacity to produce customized labels for specific regions or promotions. For smaller businesses and startups, it democratizes access to high-quality, professional labels that were once only attainable for large corporations.

The demand for shorter runs is driven by several factors:

- Product Proliferation: Consumers today have more choices than ever, leading brands to offer a wider variety of SKUs.

- Personalization Trends: Consumers appreciate personalized products and packaging, driving demand for variable data printing.

- Sustainability Initiatives: Reducing waste and overproduction is a key goal for many companies, favoring on-demand, shorter print runs.

- Global Supply Chains: The need for rapid response to market changes and localized marketing campaigns necessitates faster label production.

Narrow-web digital printing, powered by LED UV curing, is the ideal solution for meeting these evolving market needs. It allows for the efficient production of labels for everything from craft beverages and artisanal foods to pharmaceuticals and high-tech components, where frequent product updates or small batch runs are common.

The Future is Digital and Sustainable

As digital printing technology continues to mature and LED UV curing systems become even more sophisticated, the advantages for short-run label production will only grow. The industry is moving towards a model of highly efficient, on-demand manufacturing. Narrow-web digital label printing, combined with the speed, efficiency, and environmental benefits of LED UV curing, is at the forefront of this transformation, ensuring that businesses can meet the demands of a dynamic market with agility, quality, and cost-effectiveness. This powerful combination is not just about printing labels; it’s about enabling innovation and optimizing production in today’s fast-paced commercial landscape.