In the competitive world of premium label printing, speed and quality are paramount. Achieving both requires a meticulously designed workflow, especially when leveraging the benefits of UV flexographic (flexo) printing. This method offers a compelling combination of efficiency and superior print results, making it a go-to choice for a wide range of demanding applications. Understanding how to build and optimize a high-speed UV flexo workflow is key to unlocking your operation’s full potential.

The Foundation: Understanding UV Flexo Technology for Labels

UV flexo printing utilizes a raised image carrier (flexo plate) to transfer ink onto the substrate. The “UV” aspect refers to the use of ultraviolet light to instantly cure, or dry, the ink. This rapid curing is a game-changer for high-speed printing, preventing ink smudging and allowing for faster production speeds.

For label printing, flexo is particularly well-suited. Its ability to handle a wide array of substrates, from pressure-sensitive papers and films to shrink sleeves, makes it incredibly versatile. The inherent flexibility of the printing plates also allows for excellent ink transfer on uneven or textured surfaces, crucial for premium finishes.

High-Speed Considerations: What Drives Efficiency?

When we talk about “high-speed” in UV flexo label printing, we’re referring to achieving maximum output without sacrificing quality. Several factors contribute to this:

- Press Speed: The mechanical capabilities of the printing press itself are the primary driver. Modern narrow-web flexo presses are engineered for high rotational speeds.

- Ink Curing Efficiency: The speed at which UV inks cure directly impacts how fast the press can run. Faster curing means less waiting time between print stations and a more continuous operation.

- Substrate Handling: Smooth and consistent feeding and winding of the substrate are essential. Any snagging or deviation can halt production.

- Plate Technology: The durability and precision of photopolymer plates ensure consistent ink transfer even at high speeds.

- Anilox Roll Selection: The correct anilox roll cell volume and count are critical for precise ink transfer, preventing both under-inking (poor coverage) and over-inking (ink spread, loss of detail).

Integrating LED UV Curing: The Modern Advantage

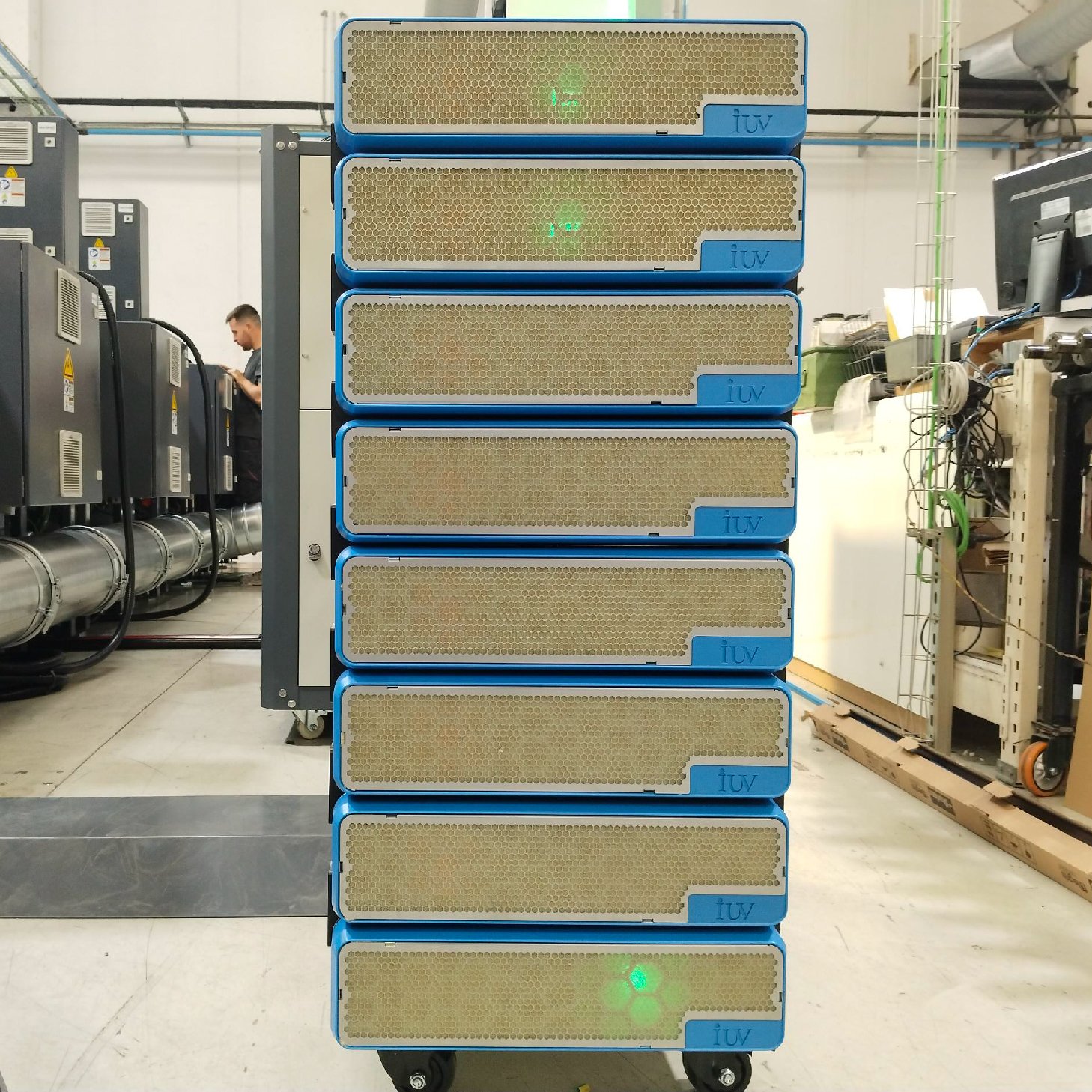

Traditional UV curing systems use mercury lamps. However, Light Emitting Diode (LED) UV curing technology has emerged as a superior alternative for many applications, especially in high-speed workflows.

LED UV offers several advantages:

- Instant On/Off: Unlike mercury lamps that require warm-up and cool-down periods, LEDs can be switched on and off instantaneously. This saves energy and allows for precise control, especially for intermittent printing or short runs.

- Lower Heat Output: LEDs generate significantly less heat than mercury lamps. This is a major benefit when printing on heat-sensitive substrates, preventing distortion or damage. It also contributes to a more stable printing environment.

- Longer Lifespan: LED lamps have a much longer operational lifespan, reducing maintenance costs and downtime associated with lamp replacements.

- Energy Efficiency: LEDs consume less power, leading to lower operational expenses.

- Wavelength Specificity: LEDs emit specific wavelengths of UV light, which can be precisely matched to the photoinitiators in UV inks, leading to more efficient and thorough curing. This is vital for achieving full cure at high speeds.

Designing Your High-Speed UV Flexo Workflow: Key Components

Building an effective workflow involves carefully selecting and integrating each component.

1. The Printing Press:

- Narrow-Web Focus: For most premium label printing, narrow-web flexo presses (typically under 20 inches in web width) are the standard. They offer the agility and precision required for intricate designs and variable data.

- Robust Construction: A high-speed press needs a rigid and stable frame to minimize vibration. This ensures consistent print quality and plate-to-plate registration.

- Automated Controls: Features like automated registration control, tension control, and automated wash-up systems significantly reduce setup times and operator intervention, contributing to higher throughput.

- Modular Design: Presses that allow for easy addition or reconfiguration of print stations and converting units offer future flexibility.

2. Printing Plates and Tooling:

- High-Quality Plates: Invest in photopolymer plates known for their durability and fine detail reproduction. Thermal or computer-to-plate (CTP) technologies offer excellent consistency.

- Precision Sleeves and Mandrels: For high-volume runs, using sleeves on air mandrels can reduce setup time and improve run consistency compared to solid plates.

- Appropriate Plate Thickness: The correct plate thickness impacts ink transfer and dot gain. Experimentation and consultation with plate manufacturers are key.

3. Ink Systems and UV Curing:

- High-Performance UV Inks: Select UV inks formulated for high-speed flexo printing. These inks are designed to cure rapidly under UV or LED UV light, offering excellent adhesion, scratch resistance, and color vibrancy.

- LED UV Integration: Plan for adequate LED UV curing units. The number and power of the units will depend on the press speed, ink type, and substrate. Ensure the LEDs are positioned correctly to provide full cure across the entire web width.

- Ink Fountain and Delivery: Efficient ink fountains and precise ink delivery systems are crucial. Servo-controlled ink fountains can help maintain consistent ink levels at high speeds.

- Anilox Rolls: Choose ceramic or coated anilox rolls with appropriate line screens and cell volumes for each color. Higher line screens generally provide finer detail but require more precise ink control.

4. Substrate Management:

- Consistent Substrates: Work with reliable suppliers who provide consistent substrate quality. Variations in caliper, surface energy, or coating can impact printability and curing.

- Effective Tension Control: Modern presses incorporate sophisticated tension control systems. Maintaining the correct tension prevents web wander, stretching, and ensures consistent dot placement.

- Winding and Unwinding: High-speed unwind and rewind units with splice detection and automatic splice capabilities minimize downtime.

5. Pre-press and Workflow Automation:

- Color Management: Robust color management ensures consistency across different jobs and print runs.

- Automated Proofing: Digital proofing systems help catch errors before they reach the press, saving time and material.

- Job Management Software: Software that integrates job specifications, plate production, and press scheduling streamlines the entire process.

Troubleshooting and Optimization for Peak Performance

Even with the best equipment, challenges can arise. Here are common areas for optimization:

- Ink Transfer Issues: If ink transfer is inconsistent, check anilox roll condition, ink viscosity, plate mounting, and squeegee pressure. At high speeds, these variables become amplified.

- Dot Gain: Excessive dot gain can lead to muddy images. This could be due to plate issues, ink too thin, incorrect anilox selection, or over-enthusiastic UV curing that causes ink spread.

- Curing Problems: Insufficient cure can lead to smudging or poor rub resistance. Ensure the LED UV system is correctly aligned and providing adequate energy. Check the ink’s specified cure speed against the press speed.

- Registration Drift: At high speeds, maintaining perfect registration is challenging. Invest in good automated registration systems and ensure the press frame is rigid.

- Web Handling: If you experience web breaks or wrinkles, re-evaluate tension settings, air circulation, and the condition of rollers.

The Future of Premium Label Printing with UV Flexo

The demand for high-quality, visually striking labels continues to grow. Building a high-speed UV flexo workflow, particularly one incorporating efficient LED UV curing, positions your printing operation at the forefront of this trend. It enables you to deliver exceptional product with greater speed and cost-effectiveness, giving you a significant competitive edge in the premium label market. By focusing on the integration of press technology, advanced curing solutions, and streamlined pre-press processes, you can unlock new levels of productivity and print excellence.