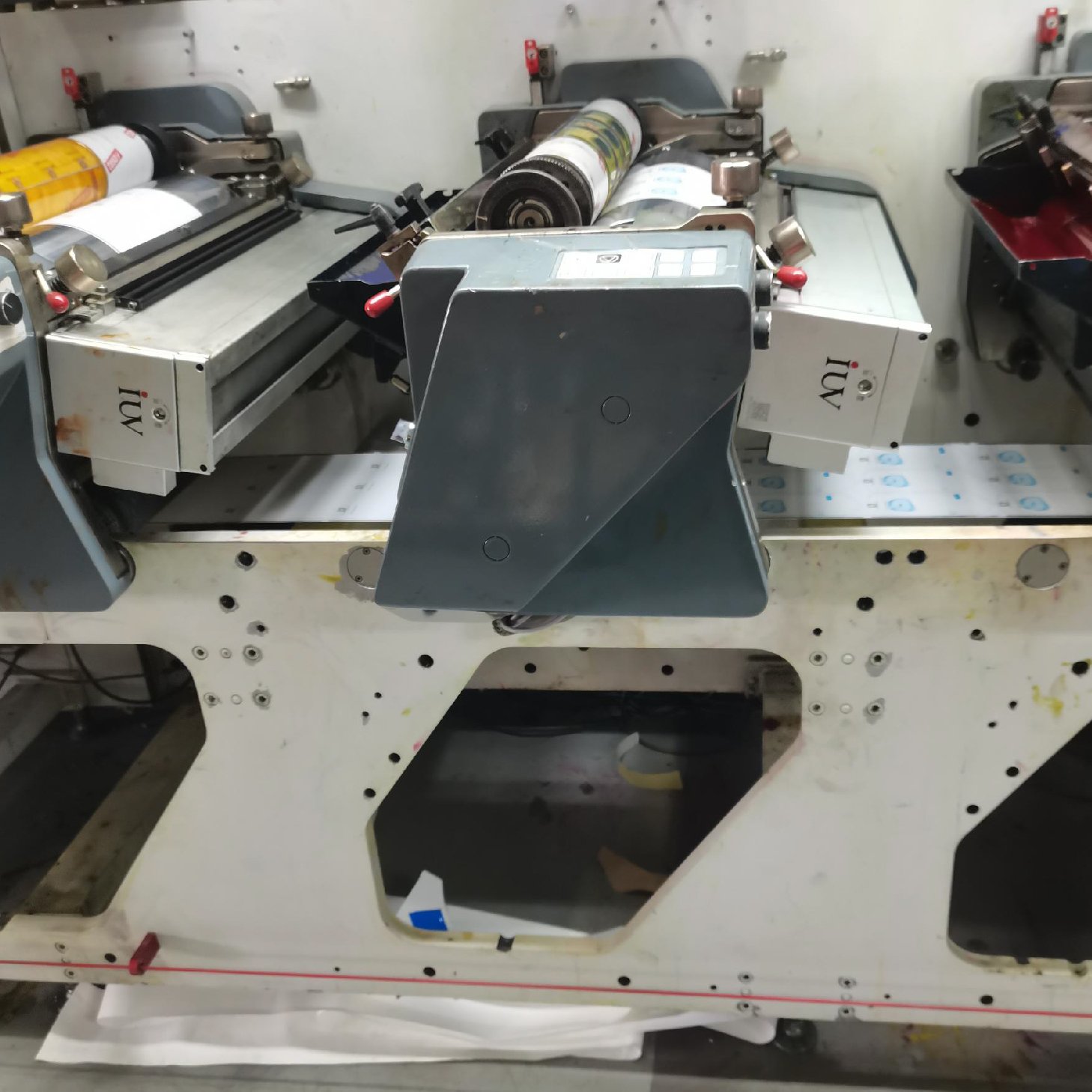

The world of printing is constantly evolving, driven by the relentless pursuit of higher quality, greater efficiency, and reduced environmental impact. In the realm of offset printing, particularly for narrow web applications like labels and flexible packaging, achieving superior dot control and accelerating turnaround times are paramount. This is where the integration of high-intensity LED curing systems presents a transformative opportunity. Moving beyond traditional UV lamp technology, LED curing offers distinct advantages that directly address these critical printing demands.

The shift towards LED UV curing in offset printing is not merely a technological upgrade; it represents a fundamental enhancement of the entire print production process. For label printers and those in the flexible packaging sector, where every micron matters and speed is of the essence, the benefits are tangible and immediate. This advanced curing technology directly impacts the final print quality, the operational efficiency, and even the sustainability of the printing operation.

The Precision of Dot Control: Sharper Images, Vibrant Colors

One of the most significant challenges in offset printing is maintaining the fidelity of fine details and achieving consistent color reproduction. Dot gain, the phenomenon where ink dots spread and enlarge during the printing and drying process, can lead to a loss of sharpness and muddied colors. High-intensity LED curing systems offer a superior solution to this problem.

Unlike conventional UV lamps that emit a broad spectrum of light, including heat-generating infrared radiation, LEDs produce a highly focused and specific wavelength of UV light. This targeted energy delivery cures the ink much more rapidly and uniformly across the printed surface. The faster and more controlled curing process minimizes the time available for ink spread, resulting in sharper dots and improved image definition. For printers producing high-resolution graphics, intricate text, or demanding brand colors, this enhanced dot control translates directly into superior print quality. The ability to lay down smaller, crisper dots means greater detail can be reproduced, and a wider gamut of colors can be achieved with greater accuracy. This is particularly crucial in label printing where brand perception is heavily influenced by the visual appeal of the product packaging.

Accelerating Turnaround Times: From Press to Finished Product in Record Time

In today’s fast-paced market, speed is a competitive advantage. Customers demand shorter lead times, and printers need to maximize press uptime. Traditional UV curing systems, while effective, often require a longer curing time and can generate significant heat, necessitating cooling and potentially limiting press speeds. High-intensity LED curing systems revolutionize turnaround times.

The intense, focused UV output of LED arrays allows for extremely rapid ink curing. This means that inks can be fully cured almost instantaneously as they pass through the curing station. This near-instantaneous cure enables presses to run at significantly higher speeds without compromising ink adhesion or print quality. For narrow web offset presses, often operating at hundreds of meters per minute, this acceleration is substantial. It translates into more jobs completed per shift, increased throughput, and the ability to accept rush orders with confidence.

Furthermore, the reduced heat output from LED curing systems eliminates the need for extensive cooling mechanisms that are often integral to traditional UV setups. This simplification not only reduces energy consumption but also frees up valuable press space and reduces the overall complexity of the curing station. The result is a more streamlined and efficient printing process, allowing for quicker job changeovers and a faster overall production cycle.

The Advantages of LED UV Curing Technology

The benefits of employing high-intensity LED curing systems in offset printing extend beyond just dot control and speed. Several other factors make this technology a compelling choice for modern printing operations.

Energy Efficiency: LEDs are significantly more energy-efficient than traditional UV lamps. They consume less power to produce the same amount of curing energy and generate far less waste heat. This translates into lower operating costs and a reduced carbon footprint, aligning with growing industry demands for sustainable printing practices.

Longevity and Consistency: LED modules have a much longer operational lifespan compared to conventional UV lamps, often lasting tens of thousands of hours. This reduces downtime associated with lamp replacement and ensures consistent curing performance over time, eliminating the variability that can arise from aging lamps.

Environmental Benefits: The reduced energy consumption of LEDs contributes to a more environmentally friendly printing process. Additionally, LED curing eliminates the need for mercury-containing lamps, which are often used in traditional UV systems, thereby reducing hazardous waste.

Versatility: High-intensity LED curing systems can be configured to emit specific wavelengths of UV light, allowing for optimized curing of a wide range of inks, coatings, and adhesives tailored for offset printing applications. This versatility ensures compatibility with evolving ink formulations and specialized printing requirements.

Applications in Narrow Web and Specialty Printing

The impact of high-intensity LED curing is particularly pronounced in the narrow web printing sector, which encompasses a vast array of label and packaging applications.

Label Printing: In the production of pressure-sensitive labels, shrink sleeves, and in-mold labels, precise registration, vibrant colors, and durable finishes are essential. LED curing enables offset printers to achieve these qualities with greater ease and speed. The ability to cure inks instantly on heat-sensitive substrates, such as some films used for labels, is a significant advantage.

Flexible Packaging: For short runs of flexible packaging, where customization and rapid delivery are key, LED curing offers a distinct edge. It facilitates the printing of high-quality graphics on a variety of filmic materials, ensuring excellent adhesion and rub resistance. The faster turnaround times allow for more agile production and quicker market entry for new product lines.

Specialty Printing: Beyond labels and packaging, LED curing systems are finding applications in other areas of offset printing where enhanced dot control and speed are beneficial, such as commercial printing of high-end brochures, postcards, and other marketing collateral where premium finish and rapid delivery are expected.

Addressing Challenges and Future Outlook

While the advantages are clear, successful implementation of high-intensity LED curing requires careful consideration. Ink formulation is a critical factor; printers must ensure their chosen inks are specifically designed for LED UV curing. Compatibility with existing offset printing presses is also a key consideration, as are the initial investment costs for the LED curing equipment.

However, as the technology matures and adoption rates increase, the economics continue to improve. The long-term savings in energy, reduced downtime, and enhanced print quality often outweigh the initial investment. The future of offset printing, especially in speed- and quality-sensitive markets like narrow web, is undoubtedly linked to advanced curing technologies. High-intensity LED curing systems represent a significant leap forward, offering printers the precision needed for superior dot control and the speed required to thrive in today’s competitive landscape. Embracing this technology is not just about staying current; it’s about unlocking new levels of performance and profitability.