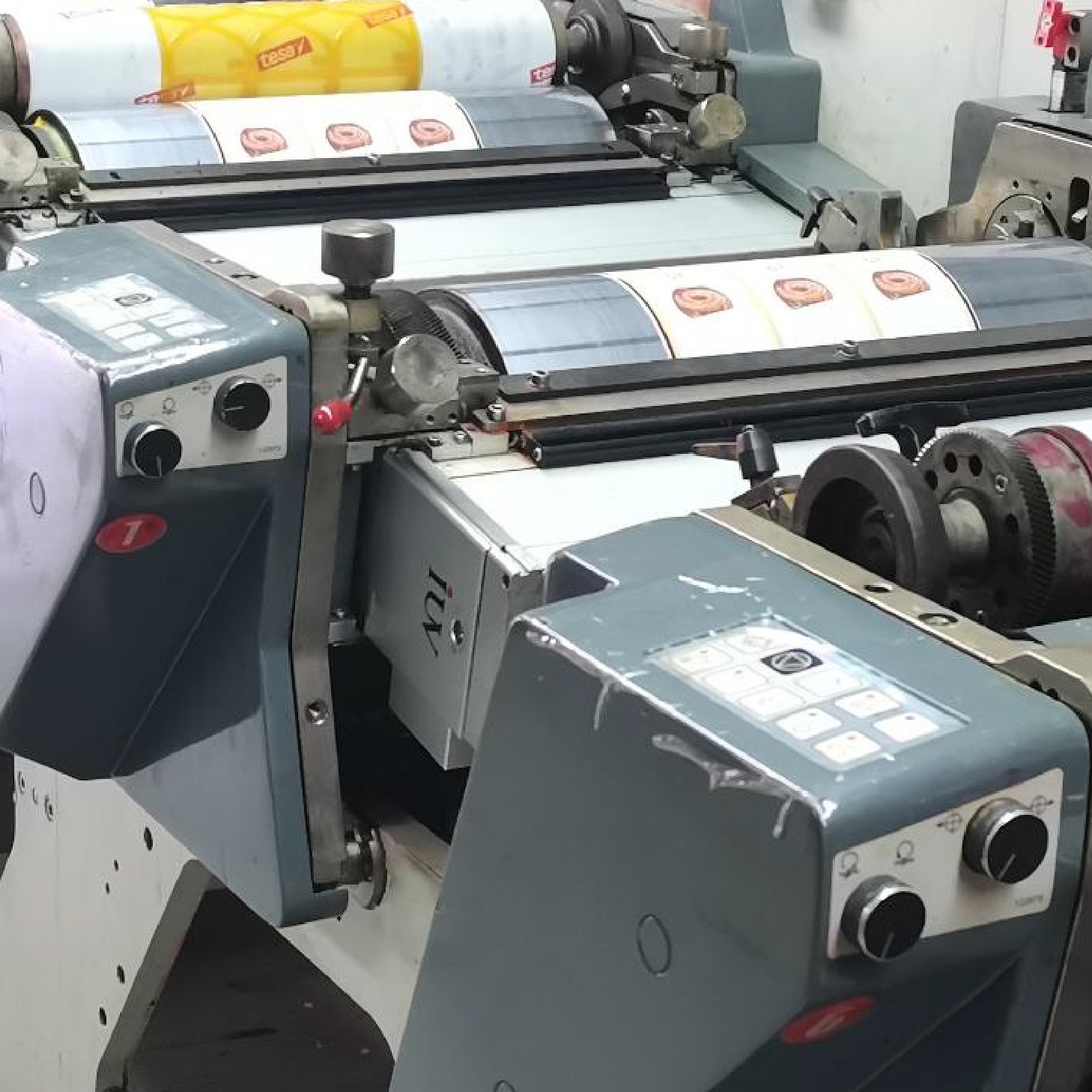

Printing vibrant, durable labels on challenging materials like films, foils, and synthetic papers demands a precise understanding of UV ink performance. These substrates, while offering unique aesthetic and functional benefits, present specific hurdles for ink adhesion, curing, and long-term durability. Optimizing UV ink formulations and printing processes is key to achieving superior results in narrow web, flexographic, and offset printing applications.

The Unique Demands of Film, Foil, and Synthetic Substrates

Traditional paper-based substrates absorb ink to some degree, aiding in adhesion. Films, foils, and synthetics, however, are non-porous. This lack of absorbency means that UV ink must form a strong bond on the surface. Any compromise in ink formulation or curing can lead to issues like delamination, scratching, or poor rub resistance, severely impacting the perceived quality and functionality of the label.

- Films: Polypropylene (BOPP), polyethylene (PE), and polyester (PET) films offer excellent clarity, chemical resistance, and durability. However, their inherently smooth, non-polar surfaces can be difficult for inks to adhere to. Surface treatments like corona or plasma are often employed to increase surface energy, promoting better ink wettability and adhesion.

- Foils: Aluminum and other metallic foils provide a premium look and barrier properties. Their inert surface requires inks that can form a robust film without reacting with the foil or being compromised by its reflectivity, which can sometimes interfere with UV curing.

- Synthetics: Materials like Teslin® or vinyl offer tear resistance and weatherability. Their plasticized nature can sometimes lead to ink plasticization, affecting hardness and scratch resistance if not managed correctly.

Understanding UV Curing Technology

LED UV curing has revolutionized the printing industry, offering faster speeds, lower energy consumption, and reduced heat output compared to traditional mercury vapor lamps. For film, foil, and synthetic applications, understanding LED UV curing is paramount.

- Wavelength Specificity: LED lamps emit UV light at specific wavelengths, typically in the I-line (365 nm) or V-line (405 nm) ranges. Ink formulations must be designed with photoinitiators that efficiently absorb these specific wavelengths to ensure complete and rapid polymerization (curing).

- Irradiance and Dose: Irradiance refers to the intensity of UV light, while dose is the total energy delivered. Insufficient irradiance or dose will result in under-cured ink, leading to poor adhesion, ghosting, and reduced physical properties. Over-curing, while less common, can lead to brittleness and cracking.

- Heat Management: While LEDs generate less heat than mercury lamps, heat can still build up on the substrate, especially at high speeds. This can affect dimensional stability of films and potentially impact ink performance. Proper ventilation and substrate cooling are important considerations.

Optimizing UV Ink Formulations

Achieving optimal performance on these demanding substrates relies heavily on the UV ink’s chemical composition.

- Adhesion Promoters: Specialized adhesion promoters are critical. These additives are designed to chemically bond with the substrate surface or improve the wetting of the ink, ensuring a tenacious hold. For challenging plastics, adhesion to low-surface-energy materials is a primary concern.

- Resin Systems: The choice of binder resins dictates many of the ink’s physical properties. For films and synthetics, flexible resins are often preferred to prevent cracking as the substrate bends or stretches. Resins must also offer excellent chemical resistance and scratch hardness. For foils, resins need to form a hard, glossy film that complements the metallic substrate.

- Pigment and Dye Selection: Pigments must be compatible with the UV curing system and not inhibit photoinitiator activity. High-performance pigments are necessary to achieve vibrant colors that remain stable under UV exposure and resist fading or bleeding. For transparent films, the optical clarity of the ink system is also a factor.

- Photoinitiator Packages: The photoinitiator system is the heart of UV curing. It must be carefully selected to efficiently absorb the LED light at the specific wavelength used. Different photoinitiators have varying absorption spectra and reactivity. A well-balanced photoinitiator package ensures through-cure without surface tackiness.

Process Considerations for Enhanced Performance

Beyond ink formulation, printing process parameters play a vital role.

- Ink Transfer and Laydown: Consistent and controlled ink transfer is essential. In flexography, anilox roll selection is critical for achieving the right ink film thickness without over-application. In offset, the balance of ink and water (if applicable) and the press settings must be meticulously managed. Too thin a film may not have sufficient pigment or binder for durability, while too thick a film can lead to curing issues and ink waste.

- UV Curing Station Setup: Ensuring the UV lamps are properly positioned relative to the substrate and that the irradiance levels are correctly calibrated for the specific ink and substrate combination is crucial. Regular maintenance and measurement of UV output are non-negotiable. The number of UV lamps and their arrangement (in-line or inter-deck) also influence cure speed and effectiveness.

- Substrate Surface Preparation: As mentioned, corona or plasma treatment is often necessary for films and some synthetics to enhance surface energy. The effectiveness of these treatments can degrade over time, so ensuring fresh treatment just before printing is ideal.

- Press Speed and UV Power Relationship: There is a direct relationship between press speed and the UV energy delivered. Higher speeds require higher UV irradiance to achieve the same dose. Operators must understand this dynamic and adjust UV power accordingly. Inadequate curing at high speeds is a common failure point.

Troubleshooting Common Issues

When problems arise, a systematic approach is needed.

- Poor Adhesion: This often points to an issue with surface energy (lack of treatment), incorrect ink formulation (inadequate adhesion promoters), or insufficient UV cure.

- Scratch and Rub Resistance: This is typically a function of the resin system’s hardness and the degree of cure. Ensure the ink is fully polymerized and consider if a higher-performance resin is needed.

- Ink Tackiness: This is a classic sign of incomplete UV curing. Re-evaluate the UV dose, photoinitiator package, and any potential inhibitors in the ink or on the substrate.

- Ink Transfer Issues: Feathering, mottling, or thin ink films can be related to anilox cell volume, ink viscosity, or doctor blade settings.

By combining advanced UV ink technology with meticulous process control, printers can unlock the full potential of film, foil, and synthetic label materials. This synergy ensures labels not only look exceptional but also perform reliably in their intended applications, meeting the rigorous demands of modern branding and product protection.