Narrow-web printing presents unique challenges. Especially when dealing with substrates that react poorly to heat. This is a common concern in label and flexible packaging production. The demands for vibrant colors, durability, and fast turnaround times are ever-increasing. Achieving these goals requires a deep understanding of UV ink behavior. It also demands careful consideration of the printing process.

Heat-sensitive substrates can deform, shrink, or degrade under elevated temperatures. This poses a significant hurdle for traditional curing methods. Fortunately, LED UV curing technology offers a solution. It allows for highly efficient curing with minimal heat generation. This makes it an ideal choice for delicate materials. However, simply switching to LED UV is not enough. Fine-tuning the ink and process parameters is crucial for optimal results.

Understanding the Substrate’s Thermal Limits

Before diving into ink formulation and curing, it’s vital to know your substrate. Different materials have different thermal thresholds. For instance, thin polyethylene films might start to soften at much lower temperatures than thicker polyester films. Paper-based stocks can also exhibit moisture-related expansion and contraction with heat. Understanding these limits helps prevent premature substrate degradation. It ensures the print quality remains high throughout the production run.

Print converters must consult substrate datasheets. They should also conduct their own thermal testing if necessary. This might involve using a thermal imaging camera or a small-scale oven test. Knowing the point at which the substrate begins to change dimensionally or optically is key. This information informs decisions about press speed, dryer temperatures, and UV lamp intensity.

The Role of UV Ink Formulation

UV inks are designed to cure via ultraviolet light. This process involves photoinitiators within the ink. These initiators absorb UV energy and trigger a polymerization reaction. This reaction transforms the liquid ink into a solid, durable film. For heat-sensitive substrates, the ink formulation itself plays a critical role.

Pigment selection is paramount. High pigment loading can sometimes lead to increased viscosity. This might require higher energy input for proper flow and transfer. Certain pigments can also absorb UV light, potentially interfering with the curing process or contributing to localized heat buildup. Careful pigment dispersion is also important. Poor dispersion can lead to inconsistent curing and weak adhesion.

The resin system is another critical component. It dictates the ink’s rheology, adhesion, and final film properties. For narrow-web applications, especially flexography, inks need to have specific flow characteristics. They must transfer cleanly from the anilox roll to the plate and then to the substrate. Resins that cure too slowly can lead to smudging or blocking, even with UV curing. Resins that cure too quickly might result in brittleness or poor adhesion.

Additives, such as slip agents or adhesion promoters, can also impact thermal behavior. Some additives might decompose or volatilize at elevated temperatures. This can affect print quality and cause press issues. Formulators must select additives compatible with both the UV curing process and the substrate’s thermal profile.

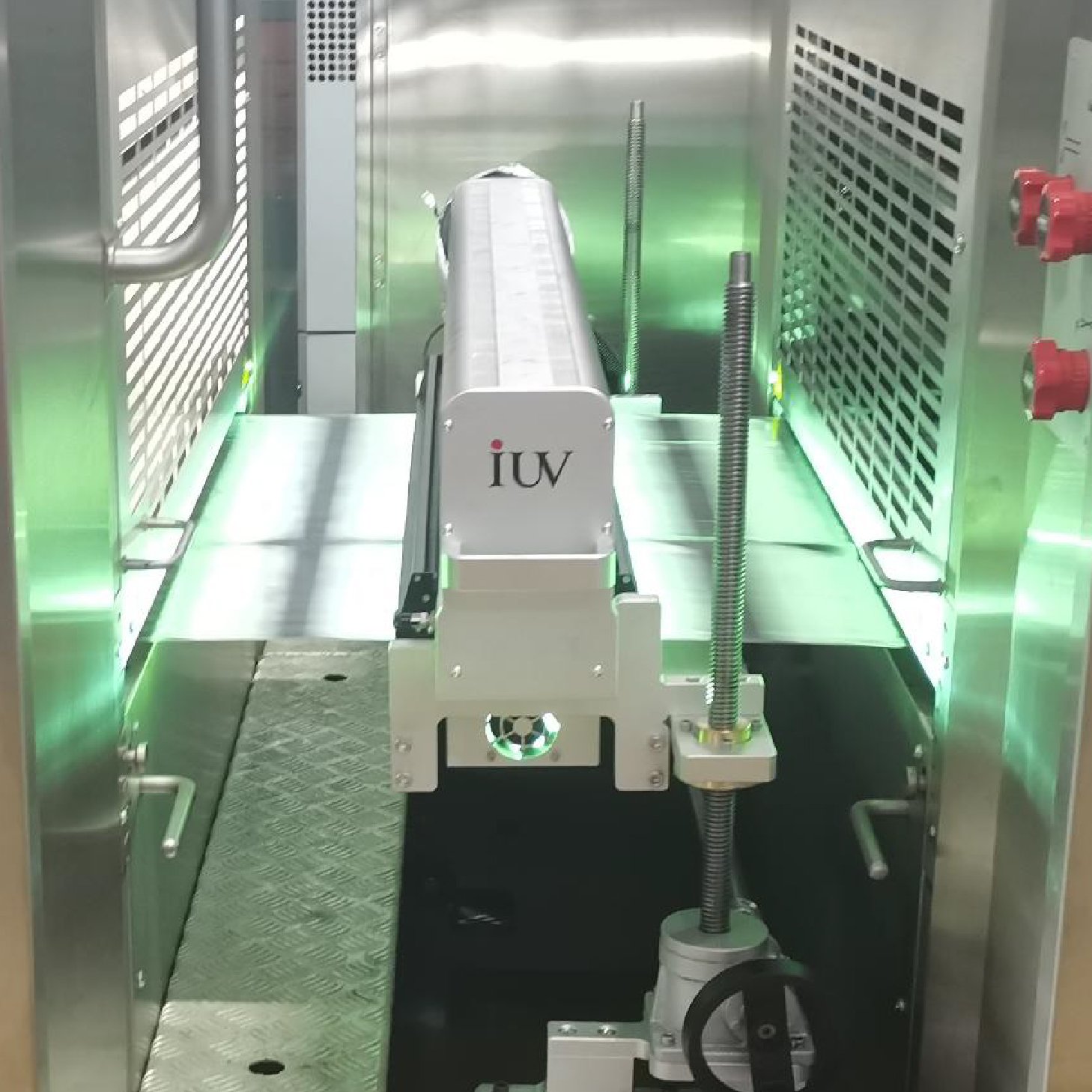

Advantages of LED UV Curing for Sensitive Substrates

Traditional mercury vapor UV lamps generate significant heat as a byproduct of their operation. This heat can easily transfer to the substrate, leading to the problems mentioned earlier. LED UV curing systems, on the other hand, emit UV light within very specific wavelengths. They do this with much higher energy efficiency. This means less wasted energy and, consequently, less heat generated.

The focused spectral output of LEDs also allows for more targeted curing. This can lead to faster cure speeds. Faster speeds mean less dwell time for heat to build up on the substrate. Furthermore, LED lamps can be switched on and off instantly. This allows for precise control over energy delivery. It also reduces the overall heat load on the press and the material.

The spectral output of LED lamps can also be tailored. This allows for better matching with the absorption characteristics of specific UV ink formulations. This optimization ensures efficient polymerization without excessive energy input. This is particularly beneficial for achieving a complete cure on heat-sensitive materials.

Flexographic Printing Considerations

Flexography is a dominant printing method in the narrow-web label industry. When printing on heat-sensitive substrates with UV inks, several flexo-specific factors come into play. Anilox roll selection is critical. Anilox volume and cell count affect ink transfer. Too much ink can increase the energy required for curing. Too little can result in poor opacity and color strength.

Plate material and hardness also influence print quality and ink laydown. Softer plates might conform better to slightly distorted substrates. However, they can also lead to dot gain. The interaction between the ink, plate, and anilox must be balanced. This balance ensures consistent ink transfer and an even ink film thickness. An even film is easier to cure efficiently.

Press speed is a direct determinant of substrate exposure time to heat. Higher press speeds generally mean less heat buildup, assuming efficient cooling between stations. However, faster speeds can also increase friction and mechanical stress. These factors can also contribute to substrate issues. Careful press speed optimization is therefore necessary. It requires balancing production efficiency with material integrity.

Offset Lithographic Printing Adjustments

While flexography is common, offset lithography is also used in narrow-web printing. For UV offset on heat-sensitive substrates, ink transfer is typically more uniform than in flexo. However, ink film thickness can be higher. This necessitates careful control of the ink-water balance and fountain solution. Too much moisture can also affect certain heat-sensitive materials.

The rollers in an offset press can also generate heat through friction. This needs to be managed. With UV offset, ensuring the ink is designed for the specific wavelength output of the LED UV lamps is crucial. The ink formulators must consider the ink’s rheology for proper transfer from plate to blanket to substrate. Poor rheology can lead to printing defects. These defects can be exacerbated by substrate heat sensitivity.

Optimizing UV Lamp Settings

The core of LED UV curing lies in controlling the lamp settings. This includes power output, exposure time, and wavelength. For heat-sensitive substrates, the goal is to deliver enough UV energy for a complete cure. This must be done without exceeding the substrate’s thermal limits.

Power output, often measured in Watts per square centimeter (W/cm²), directly relates to the intensity of the UV light. Higher power means faster curing, but also potentially more heat. It is advisable to start with a moderate power setting and gradually increase it. Monitor the substrate temperature closely. Use non-contact infrared thermometers or thermal cameras for accurate readings.

Exposure time is determined by the speed of the press and the placement of the UV lamps. For a given press speed, the exposure time is fixed. If the initial cure is insufficient at a moderate power setting, increasing the press speed is usually not an option without impacting throughput. Instead, adjusting the lamp intensity or the number of lamps in the curing bank becomes necessary.

Wavelength is fundamental to LED UV curing. Different LED emitters produce UV light at specific wavelengths, commonly in the UVA range (320-400 nm). Ink formulations are optimized for particular wavelengths. Ensure the LED lamps’ spectral output precisely matches the photoinitiators in the UV ink. Mismatched wavelengths result in inefficient curing, requiring more energy and potentially leading to overheating.

Advanced Techniques and Best Practices

To further optimize UV ink performance on heat-sensitive narrow-web substrates, consider these advanced techniques:

- Spot Curing: Instead of curing the entire web continuously, consider spot curing. This involves strategically placing UV lamps only where ink has been applied. This minimizes overall heat exposure to the substrate.

- Web Cooling: Employ air knives or chilled rollers immediately after the UV curing station. This rapidly cools the substrate, dissipating any absorbed heat before it can cause damage.

- Ink System Management: Ensure the ink is stored correctly and mixed thoroughly before use. Over-agitated inks can introduce air, affecting viscosity and curing. Degassing ink might be necessary in some high-speed applications.

- Test Runs and Monitoring: Always perform thorough test runs before committing to a full production batch. Continuously monitor print quality, adhesion, and substrate integrity throughout the run. This includes regular checks for color consistency and any signs of ink film defects.

- Collaboration with Ink Suppliers: Work closely with your UV ink supplier. They can recommend specific ink formulations optimized for LED UV curing and heat-sensitive applications. They may also have insights into compatible additives and resin systems.

By carefully considering substrate properties, ink formulation, and the nuances of LED UV curing technology, printers can successfully navigate the challenges of heat-sensitive narrow-web substrates. This approach ensures high-quality output and maintains production efficiency.